Moment Montage liquid nails: features and benefits

Moment Montage liquid nails are a versatile tool for fastening various parts, trim elements and decor without the use of screws and nails. Ease of use and aesthetic result have made it possible to use the adhesive in many types of renovation work.

Specifications

Liquid nails are composed of a large number of fine-grained fillers. This allows not only to glue, but also to seal the cracks. They perfectly bond wood, plasterboard, gypsum, ceramic and cork surfaces. Some types stick together glass, stone, metal.

Moment Montage liquid nails can be divided into two large groups according to their composition: based on synthetic resins and polyacrylate-water dispersion. This directly affects the properties of the glue, its technical characteristics and application.

"Moment Montage" based on synthetic resins contains rubber and organic solvents. Thanks to the latter, it has a pungent unpleasant odor and is easily flammable until it hardens. Handle rubber nails in a well-ventilated area. They are only suitable for construction and installation work.

Cannot be used for mounting PVC or foam panels. The composition can withstand temperatures below 200 ° C. This option is marked with MR.

Technical characteristics of rubber nails:

- seams withstand prolonged contact with water;

- perfectly bond smooth and non-absorbent surfaces;

- can be used as a sealant;

- thanks to the elasticity of the glue, the seams are resistant to vibration;

- excess mixture is removed only with a solvent;

- dissolve the plastic.

Nails based on polyacrylate water dispersion are chemically neutral. They can be used for interior renovation work: glue PVC panels, plastic skirting boards, baguettes, ceiling tiles. And although the hardened joint can withstand negative temperatures, the glue itself is stored and set at temperatures from +5 to + 300 ° C. It is marked on the MB packaging.

Technical characteristics of acrylic nails:

- do not have a pungent unpleasant odor;

- can be used to fill gaps;

- resistant to atmospheric moisture, but cannot withstand prolonged contact with water;

- after drying, it can be painted with dispersed paints;

- universal;

- at least one of the surfaces must absorb water well;

- excess can be easily removed with a damp cloth.

"Moment Montage" can also be divided according to the type of materialfor example, only for plastic. Nails are available in white or transparent (marking with a small letter "p"). The choice of liquid nails depends on the intended scope of work. If the seams come in contact with water, and the surfaces are smooth, non-absorbent, and the elements are large, then it is better to choose an adhesive based on synthetic resins. If you need to glue plastic elements of decoration, decor, repair work is carried out in living rooms, then it is better to use acrylic nails.

If the adhesive is high or the shelf life of 1.5 years has expired, then it is disposed of as normal household waste. Under no circumstances should it be released into the sewer. The composition of liquid nails is extremely toxic to fish.

Views

The Moment Montage line includes about sixteen products. Depending on the materials and the complexity of the upcoming work, you can easily choose the most suitable adhesive composition. It is determined by the corresponding marking (MB and MP).The numbers next to it indicate the initial setting strength (kg / m²).

- "Moment Montage - Express" MV-50 applies to all types of work. It does not contain solvents, is moisture resistant, and is suitable for the installation of wood, PVC and insulation panels. It can be used to attach skirting boards, door frames and decorative elements.

- “One for everything. Super strong " made with Flextec technology. The adhesive has an elastic structure, one-component. It has a wide range of applications, high initial strength (350kg / m²), therefore it is ideal for large and heavy structures. Suitable for all surfaces regardless of porosity. It is possible to fill gaps, seal static joints. Moisture cures and can be applied to wet surfaces. It adheres to concrete and brick walls, glues natural stone. Not suitable for glass, copper, brass and PVC.

- “One for everything. Transparent" has the same properties as Super Strong. Often used for urgently sealing joints underwater, but not suitable for permanent immersion. It has a shorter shelf life, only 15 months.

- "Moment Montage - Express" MV-50 and "Decor" MV-45 it is characterized by fast gluing, it is used for fixing decorative elements made of various materials. The best adhesion will be on hygroscopic surfaces.

- "Moment Installation. Waterproof "MV-40 characterized by resistance to moisture class D2 and versatility, provides a strong bond of any material.

- "Moment Installation. Super Strong "MVP-70 Transparent glues quickly enough, while the load is up to 70 kg / m². It is used for the installation of wall panels and decorative elements. On sale there is a super-strong MB-70 white.

- "Moment Installation. Super Strong Plus "MV-100 has the same technical characteristics as Superstrong MB-70, only the gripping force is much higher - 100 kg / m². For fastening heavy elements, it does not require supports and clamps.

- "Moment Installation. Extra strong "MR-55 presented on the basis of rubber, suitable for heavy structures, holds any materials.

- "Moment Installation. Universal "MP-40 presented on the basis of synthetic rubber, while being easily washed off. It is suitable for fixing fiberboard, concrete walls, marble or natural stone masonry, polystyrene bathtub panels, fiberglass, glass surfaces. Bonds quickly, reliable. Can be stored at sub-zero temperatures down to -20 degrees.

- "Moment Installation for panels" MR-35 specially designed for fixing polystyrene or foam panels. It bonds the same materials as the Universal MP-40, is characterized by strength, but is easily washed off before hardening.

- "Moment Installation. Instant grasp "MR-90 perfectly grasps from the first minutes of use, glues surfaces that do not absorb moisture. It perfectly holds polystyrene, polystyrene, brick, plywood and stone together.

- "Moment Installation. Transparent grip »MF-80 made on the basis of Flextec polymer, quickly sets. It can be used as a sealant, is transparent and does not contain solvents. It is suitable for smooth, non-absorbent surfaces.

- “The Moment of Fix. Universal ”and“ Expert ”. The fixation is almost instantaneous, the setting force is 40 kg / m². Used only for indoor work. If glue is not used, it must be kept closed, as it quickly forms a film. It is designed for the installation of ceiling tiles, floor skirting boards, wood and metal decorative elements, sockets, wood wall panels, as well as for filling gaps up to 1 cm.

- "Moment Installation. Polymer "toLeu is represented by a composition based on an acrylic aqueous dispersion, it is not liquid nails. It has excellent adhesion, becomes transparent when dry, and is used to fill deep gaps.They can glue paper, cardboard, polystyrene, wood, parquet mosaic, expanded polystyrene, PVC. Available in bottles.

Appointment

Liquid nails are a special durable adhesive formulated for mechanical fasteners. Bonding strength can replace screws and nails, hence the name. Perfect for installing tiles, panels, skirting boards, friezes, platbands, window sills, decorative elements. Does not require the use of impact tools during operation, but fasteners may be required to secure heavy structures. "Instant grappling" allows you to quickly complete all installation work. The polarization time is about 15 minutes, during this time you can move the parts, correct the direction.

Liquid nails will not damage the working substrate and will not destroy it over time. The seam does not rust, does not rot, and is resistant to moisture and frost. The glue meets all the requirements of GOST. Usually available in 400g cartridges.

Compounds on rubber are used for the installation of heavy structures where there is high humidity. Great for natural bamboo wallpapers, tiles and mirrors. For plastic elements, PVC and polystyrene, it is better to use liquid nails based on an acrylic water dispersion. They are more versatile, less dangerous and have no chemical odor. This glue can be used in children's rooms and other living areas.

How to work with the squad?

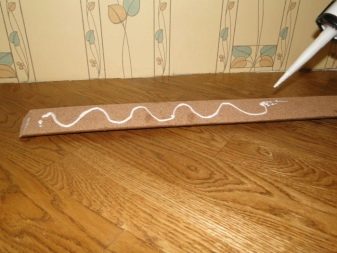

Before applying the glue, the surfaces must be cleaned and degreased. Nails are applied with an indent from the edge by 2 cm so that the glue does not come out of the seam when squeezed. If the surface is uneven, apply in spots. For small surfaces, it can be applied with a line to give greater rigidity and increase the adhesion force. For example, for ceiling tiles, it can be applied in a continuous line around the perimeter, for wall panels - in small sections.

Apply glue according to the instructions. If the nails are acrylic, then apply glue and press, holding for a few minutes, until it sets. If the nails are rubber, then apply glue, connect the surfaces, and immediately separate them so that the solvents disappear, the bonding is better. Leave for 5-10 minutes and connect completely by pressing. If the structures are heavy, then use props.

You can put a toothpick inside to keep the glue from sticking out of the joint. It will act as a limiter and set the seam thickness.

If the excess does come out, then before they dry, they can be removed by scraping off with a plastic card like a spatula. Acrylic nails can be wiped off with a damp cloth, rubber nails can be removed with a solvent. If the surface is porous, then such manipulations will spoil the appearance. In this case, it is better to wait until the excess glue is dry and carefully cut it off.

Note for beginners

- To work with liquid nails, you need to purchase a construction gun. The cartridge is inserted into it, then you need to open or cut off the tip. The composition is squeezed out with a trigger. If large-scale repair work is planned, then it is better not to save money and purchase a high-quality pistol. In cheap models, the trigger quickly fails. The gun itself is versatile and useful for working with sealant.

- If the concrete walls are fresh, then it is necessary to withstand for at least a month. This is necessary so that the surface dries well, and the concrete itself grabs. After that, you can start installation work. If PVC panels are to be glued to painted walls, they must be sanded. Acrylic nails do not adhere well to non-absorbent surfaces. According to numerous reviews, an additional primer can be applied.

- To improve adhesion to expanded polystyrene, the surface can be covered with wood glue diluted with water (1: 1). Once the primer is dry, nails can be applied. Parts are fastened with liquid nails quickly, but it will take more time to fully cure. The glue dries from 12 to 24 hours.

What to choose, hot glue or liquid nails, see the following video:

The comment was sent successfully.