Heat-resistant adhesive for metal: specifications

Heat-resistant glue for metal is a popular product for household and construction chemicals. It is widely used in auto repair and plumbing, as well as for thread repair and crack repair in metal. For the high reliability of gluing and the long service life of the repaired structures, the glue was named "cold welding" and has firmly entered modern use.

Technical characteristics of heat-resistant glue of different brands

Heat-resistant glue is a solid or liquid composition consisting of epoxy resin and a metal filler.

- Resin acts as the main component that binds the elements together.

- The metal filler is an important element of the mixture, which gives high heat resistance and reliability of the bonded structure.

In addition to the basic substances, the glue contains modifying additives, plasticizers, sulfur and other elements that give the glue the necessary texture and regulate the setting time.

Initial drying of the glue varies from 5 minutes for Penosil products to 60 minutes for Zollex glue. The time for complete drying of these compounds is 1 and 18 hours, respectively. The maximum operating temperatures for the glue start from 120 degrees for Penosil and end at 1316 degrees for the Almaz high-temperature model. The average maximum possible temperature for most compounds is 260 degrees.

The cost of products depends on the manufacturer, the form of release and the performance properties of the glue. Among the budget options can be noted "Spike", used for gluing ferrous and non-ferrous metals and produced in tubes with a capacity of 50 g. It can be purchased for 30 rubles.

Domestic brand "Super Khvat" has an optimal ratio of price and quality. The composition costs within 45 rubles per 100 g. Compositions with a narrow specialization are more expensive. For example, the cost of a 300 gram pack of "VS-10T" is about two thousand rubles, and the branded composition of "UHU Metall" costs about 210 rubles for a 30 gram tube.

Advantages and disadvantages

High consumer demand and a wide range of applications are due to a number of indisputable advantages of heat-resistant glue.

- The availability and reasonable cost of the formulations make the glue even more popular in the consumer market.

- For gluing parts by cold welding, professional skills and special welding equipment are not required.

- The ability to carry out repair work without removing and dismantling the repaired parts.

- The quick time of complete drying of some models allows you to carry out repairs on your own and in a short time.

- Unlike traditional welding, the compositions do not have a thermal effect on metal components, which is convenient when repairing complex mechanisms and sensitive assemblies.

- The high quality of the connection guarantees the continuity of the fastened elements even under the influence of mechanical stress.

- With the help of hot glue, a refractory and heat-resistant joint is formed. This is important when repairing metal structures that operate at temperatures exceeding 1000 degrees.

- No need for additional seam treatment such as sanding and leveling. This is the advantage of this group of glue over electric gas welding.

- Possibility of bonding metal with rubber, glass, plastic and wood products.

The disadvantages of heat-resistant glue for metal include the inability to eliminate major damage and malfunctions with it. There is also a long time for complete drying of some formulations, and an increase in the time of repair work. The surfaces to be glued must be thoroughly prepared using degreasing and washing of working surfaces.

Views

In the modern market, hot melt adhesives for metal are presented in a wide range. The models differ in composition, purpose, maximum operating temperature and cost. There are both universal compounds used to work on any metal surfaces, and highly specialized products.

The most popular and common are several brands of glue.

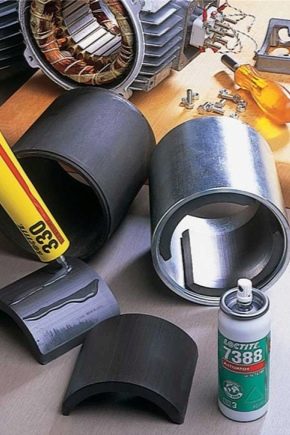

- "K-300-61" - a three-component agent consisting of an organosilicon epoxy resin, an amine filler and a hardener. The material is applied in several layers on a surface preheated to 50 degrees. Consumption for the formation of one layer is about 250 grams per sq. m. The period of complete drying directly depends on the temperature indicators of the base and varies from 4 to 24 hours. Available in 1.7 liter cans.

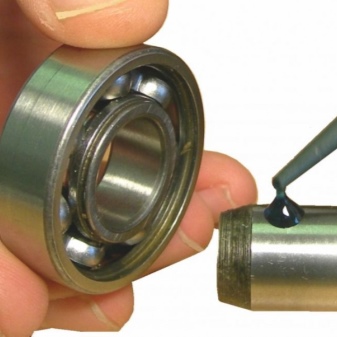

- "VS-10T" - glue consisting of special resins with the addition of organic solvents. The composition of the product includes additives of quinolia and urotropine, which allow the composition to withstand a temperature of 200 degrees for 200 hours and 300 degrees for 5 hours. The adhesive has good flow properties, which allows it to be applied at low pressures. After mounting on a previously prepared surface, the composition is left for one hour, during which the solvent completely evaporates. Then the parts to be glued are placed under a press with a set pressure of 5 kg / sq. m. and put away for two hours in an oven with a temperature of 180 degrees. Then the structure is taken out and left to cool naturally. Operation is possible 12 hours after gluing. The price of 300 grams of the composition is 1920 rubles.

- "VK-20" - polyurethane glue, which has a special catalyst in its composition, which allows it to withstand short thermal effects up to 1000 degrees. The adhesive can be used at home without preheating the surface. But in this case, the time for complete drying can be 5 days. Heating the base to 80 degrees will help speed up the process significantly. The material forms a water-resistant seam and allows you to make the surface solid and tight. The pot life of a freshly prepared mixture is 7 hours.

- Maple-812 - a household or semi-professional compound that reliably connects metal to plastic and ceramic substrates. The disadvantage of the model is the fragility of the formed seam, which makes it possible to use it on surfaces that are not subject to deformation during operation. The period of hardening of the layer at room temperature is 2 hours, and the final gluing and drying of the solution when the base is heated to 80 degrees is 1 hour. The material must not be exposed to open flames. The cost of a package of 250 g is 1644 rubles.

Criterias of choice

When choosing an adhesive, it is necessary to pay attention to the compatibility of this composition with the metal to be glued. The strength of the formed layer should not be less than the strength of the metal itself. Along with the maximum temperature at which a particular composition can be used, the lower permissible term definition should also be taken into account. This will prevent the possibility of cracking and deformation of the seam in conditions of negative temperatures.

Use universal formulations with caution. It is better to opt for specialized products, taking into account the materials that will stick together, for example, "metal + metal" or "metal + plastic".

When choosing the form of release of the glue, one must take into account the place of application and the type of work.When gluing microcracks, it is more convenient to use a liquid consistency, and plastic sticks will be indispensable in the event that it is not possible to knead epoxy resins and hardener. The most convenient to use are ready-made semi-liquid mixtures that do not require independent preparation and are completely ready for use. You should not buy glue for future use: the shelf life of many formulations does not exceed one year.

It should be remembered that even the toughest metal adhesive does not match the bond strength of traditional welding. If the structure is subjected to regular dynamic stress, the integrity of the butt joint will be compromised. In such cases, it is better to use welding or mechanical fasteners. If the glued part will be used at home, then there is no need to purchase expensive products with a high thermal threshold used in the aviation and automotive industries. In this case, you can get by with a budget composition with an upper term of 120 degrees.

Heat-resistant metal adhesive is an easy-to-use tool that allows you to independently carry out high-quality repairs of metal structures used in high temperatures.

In the next video, you will find an overview of the HOSCH two-component adhesive.

The comment was sent successfully.