Poxipol cold welding: pros and cons

Cold welding Poxipol, produced by the Uruguayan company of the same name, is a popular adhesive and is well known in the domestic market of household chemicals. The composition is widely used for gluing various surfaces in domestic conditions and has a high consumer demand.

Specifications

Cold welding Poxipol is a two-component epoxy adhesive with a pasty consistency and no solvent. The value of the maximum shear force of the joint is not less than 993 N with an average shear stress of 2.2 MPa, a pull-off stress of 5.4 MPa and a shear test of 237 N. The primary setting time is one hour, and full hardening occurs after a day. The solution remains plastic for 10 minutes after application, which allows, if necessary, to correct the correct location of the parts to be joined. The release form of the product is presented in two tubes with a volume of 14 to 70 ml, the contents of which are mixed immediately before use in a 1: 1 ratio.

A distinctive feature of the application of cold welding is the absence of the need to use a press and strong pressure of the glued surfaces. To ensure a reliable connection, it is enough not to expose the parts to vibration and leave them at rest for the specified time. Work with the glued surface in the form of grinding, drilling and other mechanical influences can be carried out one day after installation. Another feature of the composition is its ability to solidify in conditions of high humidity, including under water.

Advantages and disadvantages

Demand for Poxipol cold welding and a large number of positive reviews are due to a number of undeniable advantages of the material.

- The versatility of the tool lies in the possibility of gluing together materials of different structure and density.

- Ease of use and availability of material. The composition can be purchased at any hardware store or hardware store, which makes it even more popular with consumers.

- The possibility of forming a layer of any thickness is due to the stability of the composition to deformation and the preservation of the original volume after drying.

- Due to its thick consistency, the composition is excellent for working on vertical surfaces.

- The absence of solvents in the glue makes it possible to use the composition in living quarters in the presence of children and animals.

- Resistance to water makes it possible to use the glue in rooms with high humidity. The product can be used with moderate exposure to sulfuric and hydrochloric acids, gasoline and toluene.

- The material does not leave marks after drying, which allows you to glue objects without fear of streaks and stains.

The disadvantages of Poxipol cold welding include a low melting point., which is 120 degrees, which significantly limits the scope of the glue. There is a small package for the Poxipol 00266 and 00267 models, which has a volume of 14 ml, as well as a long time for the complete drying of the product. Low tensile strength values exclude the use of glue for work with parts that are prone to vibration and shock. The disadvantages include the need for thorough preparation of working surfaces with mandatory degreasing and dust removal of parts.

Application area

Poxipol cold welding has found widespread use in the home. With its help, you can glue any surfaces, as well as restore the integrity of containers and planes. The tool fixes well metal, plastic, rubber, glass, wood and concrete in any combination, and can also be used to repair car parts, furniture, toys, dishes and water pipes.

The glue has proven itself well for sealing tanks and gas tanks., as well as when repairing door fittings. The material can be used for outdoor work and used in subzero temperatures. The tool is widely used to restore damaged ceramics and for gluing decorative items. In construction and repair work, Poxipol is used to reinforce ceramic tiles, and in auto repair shops it is used to putty fenders and bumpers. The adhesive effectively removes holes in metal sheets, suitable for repairing boats, mirrors and concrete floors.

Instructions

Before proceeding with gluing parts, it is necessary to carefully prepare the working surfaces. This requires removing mechanical debris, as well as washing and degreasing the elements using a special solvent. It is necessary to combine the contents of the packages in equal parts and mix the composition thoroughly. Mixing time is usually 10 minutes. The resulting mass should be homogeneous and free of lumps. When mixing the components, the temperature of the resulting mixture increases significantly.

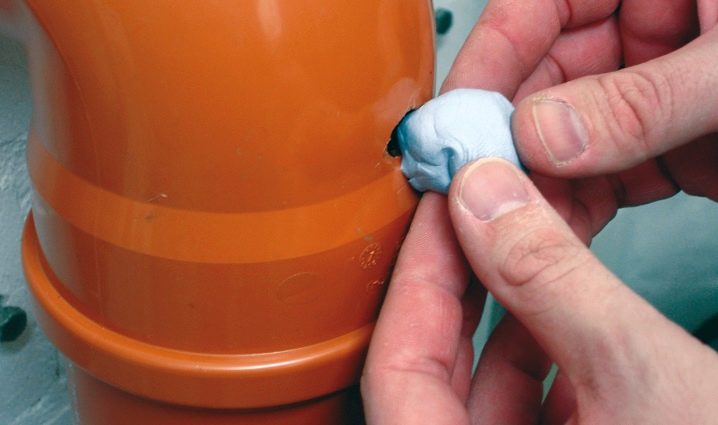

Then you should apply the resulting product to one of the surfaces and press the parts tightly against each other. To eliminate leaks in containers, you need to apply glue to the hole or crack and leave it at rest until it dries completely. You can adjust the location of the parts within 10 minutes after applying the mixture, and it is recommended to use the glued thing a day after installation.

When using Poxipol cold welding, the following precautions should be observed:

- it is necessary to exclude contact with the skin and mucous membranes;

- in case of contact of the skin of the hands with uncured glue, wash the contaminated area with soapy water, and then rinse with warm running water;

- if allergic reactions occur, it is recommended to consult a doctor;

- after complete drying, the product does not pose a danger to human health;

- when buying cold welding, you should pay attention to the expiration date, since it is forbidden to use compositions with an expired date.

Advice

Strict adherence to the rules of use and following simple recommendations will help to quickly and reliably glue any surfaces and extend the life of damaged items.

- Smoothing the mixture after application should be carried out using a rubber spatula or a knife moistened with water.

- If the mass is poorly squeezed out, you can slightly heat the tube.

- In case of partial use of the material and the presence of a residual amount of glue for the next use, it is not recommended to replace the caps of the tubes in places.

- Prepare the mixture on an easy-to-clean plate.

- It should be remembered that Poxipol does not bond Teflon, polypropylene and polyethylene surfaces.

- To join complex surfaces, a thin layer of toluene-free contact adhesive must first be applied to each of the parts. This applies to steel, bronze, copper and chrome plated products. Cold welding can be started after the auxiliary composition is completely dry.

- When gluing smooth, pore-free elements, it is recommended to clean the working areas with sandpaper or fine sandpaper. This will increase the adhesive properties of the materials and ensure their reliable connection.

- It should be borne in mind that the composition becomes transparent only 10 minutes after application. At the same time, the volume and shape of the layer does not change.

- The recommended temperature for cold welding is 20-25 degrees.A higher temperature decreases the time for complete drying, a lower temperature increases.

Poxipol cold welding will help to quickly repair any product, keep it presentable appearance and ensure high reliability of the connection.

You will learn more about working with Poxipol cold welding by watching the following video.

The comment was sent successfully.