Two-component adhesive: types and applications

For bonding various building and finishing materials, in most cases, a special adhesive is used, which includes two components. Such an adhesive provides strong and reliable adhesion of various materials. But before using this substance in the process of repair work, it is necessary to familiarize yourself in advance with its characteristics, features and scope of application, and in order not to be deceived by dishonest manufacturers, it is also important to analyze the manufacturers of two-component formulations in advance.

Peculiarities

Two-component adhesive combines two types of ingredients in its composition - special resins, as well as hardeners. The latter can have a different state of aggregation: liquid or powder. But in any case, it is necessary to carry out the main procedure before using the glue - mixing its components, which provides the material with the ability to harden.

To prepare the composition properly, you must strictly follow the instructions for its dilution.indicated on the packaging. The instruction contains information about the proportions of the ratio of components and the time required for exposure after dilution. Some formulations imply a different way of mixing the two substances. If two surfaces are to be glued, then a resin is applied to one, and a hardener is applied to the other, while the compositions are mixed directly when the two surfaces are joined.

The two-component composition quickly sets to the surface and hardens. It is also very difficult to remove. In some cases, the process of gluing or sealing with epoxy becomes irreversible, therefore it is important to carefully prepare the surface so that the adhesive composition, in addition to performing its key functions, does not contribute to the appearance of incidents in the repair.

A two-component material for bonding wood and other surfaces is often sold in buckets. One of the ingredients is presented in dry form. In this case, add the dry component to the bucket and mix both components thoroughly.

Depending on the specific brand and specific components in the composition of the epoxy, such glue can be stored from half an hour to two hours. Then it becomes unusable due to its thickening consistency.

When the composition is already applied to the surface, it will maintain its performance for 1-2 hours.

Advantages and disadvantages

Compared to other types of adhesives, two-component adhesives have a number of special positive characteristics.

These include some positions.

- High drying speed. Such a solution does not contain various solvents or aqueous components, so it can dry out after a day after application.

- High strength. Epoxy mortar sticks materials together for a long time. In addition, it can be applied to absolutely any substrate.

- Waterproof. After processing with such glue, the material will not react worse to contact with water. The glue has the ability to keep liquid out and not to absorb it. In addition, the performance of the solution will not be affected by contact with moisture.

- The adhesive solution does not allow electricity to pass through.

- The adhesion level is very high.

- The composition has an elastic structure.

- The adhesive does not have a negative effect on solid wood materials.

- After drying, the glue line does not deform.

- The material is not prone to shrinkage after a certain time after application.

- Even despite the presence of harmful substances, the glue is not dangerous, because these substances simply disappear as the composition hardens.

- The composition is not subject to the harmful effects of various bacteria and mold.

The disadvantage is the relatively high price, but among the variety of products, you can always find an option that matches your financial capabilities.

Also, some polyurethane varieties of two-component adhesives have a very caustic composition that can cause burns if they come into contact with the skin.

Views

Although two-component glue is a universal material, it still has a number of varieties, each of which has its own characteristics.

The main types of composition include several types.

- Polyurethane adhesive with epoxy component. It often becomes an alternative to fastening with self-tapping screws. This solution has 20% elasticity and is sold at an affordable price.

- An even more elastic compound specially designed for fixing to the base of parquet is a polyurethane adhesive without epoxy resins. Its elasticity index can reach 40%, but such a substance is sold at a higher price.

- Acrylic 2-component adhesive is presented in the form of such a variety as a modified composition. It includes an activator that is applied to the surface of the product. Only then can the gluing be carried out.

- Among the acrylic varieties, there is also a two-component dispersion adhesive based on water. This compound is durable due to its high level of adhesion to the surface and is environmentally friendly.

- Adhesive for PVC is a composition, the working capacity of which can last up to 8 hours. It also provides for the possibility of additional addition of hardeners. For industrial work with PVC material, such a type of two-component composition as 3M is used, which includes special equipment for application.

- A special one is a non-shrinking two-component solution, which has a transparent color. This epoxy compound is multifunctional, as it is able to fix both complex electronic parts and small decorative elements.

Scope of application

Due to the excellent adhesion of the substance, the two-component composition various types of structures can be glued.

- A two-component polyurethane compound for gluing parquet is very popular. Parquet glue adheres better to the boards if they are tapped after gluing, thereby eliminating unwanted voids.

- If it is necessary to attach plywood with dowels, two-component glue can be an alternative fastening that is not inferior in strength.

- A composition of this type is perfect for laying ceramic tiles or mosaics. Due to its special properties, the material ensures reliable adhesion of the tile covering to the base on both horizontal and vertical surfaces.

- With additional heat treatment using an adhesive, you can join parts made of metal, aluminum or other heavy materials.

- Using two-component glue, even massive products made of natural and artificial stone, for example, marble and granite, are connected to each other. These can be various panels used for interior decoration.

- Glass products can most often be broken due to their fragility. But epoxy glue will be an excellent glue when restoring the shape of dishes, vases and other glass items.

- The two-component material is used for repairing shoes, some clothing parts and accessories.

Such a widespread use of the adhesive composition makes it possible to use it in everyday life as a universal method of bonding various materials.It is enough to have one tube of such glue in the house in order to easily eliminate many breakdowns.

Sometimes epoxy is used to make specific parts. For this, the composition is poured into special forms.

During the finishing work, the adhesive is used to seal the gaps in the floor screed, which allows you to correct minor defects formed during construction.

Manufacturers

There is a variety of such compositions on the market for building and finishing materials. Let's highlight the most popular manufacturers.

- "Uzin MK 92 S" - is a unique adhesive with a very long service life. This quality is due to the increased strength of the material.

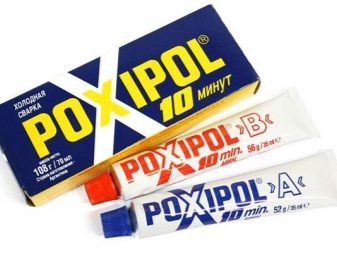

- Two-component adhesive mixture Poxipol is a unique material because it can harden even while under water. The contact adhesive does not include toluene. Within half an hour, the mixture can already dry.

- To bond heavy materials such as metal, steel, titanium or cement, use "Universal two-component composition 302"... It is sold in tubes of 10 g. It is important to remember that such a substance cannot adhere zinc, polyolefins, copper and celluloid.

- Brand glue Interbond It is used as a binder between materials made of wood, plastic, MDF, plywood and other lightweight materials. Its peculiarity lies in the fact that one of the substances is presented in the form of an aerosol, which must be sprayed onto one of the surfaces to be joined.

- Two-component composition Akfix 705 has a special structure. It never flows downwards, therefore it is a very convenient material for cladding vertical surfaces. In addition to wood and plastic, the substance also adheres to leather and rubber.

- Zionacrylate brand adhesive solutions Loctite have a wide range of applications. The company produces special types of compounds for insulating wires, gluing rubber parts, carrying out cosmetic procedures and many other types of work.

How to choose?

For many users, the choice of glue itself is difficult.

To choose the right composition, you should take into account a number of factors, which include some nuances.

- Type of work. This can be finishing work, wall cladding, parquet laying. Also, glue is used to repair and join parts. The volume of the required material directly depends on this factor. Sometimes it is enough to purchase just a 10g tube.

- The material to be glued. It defines the specific type of two-component adhesive. Not all varieties have the ability to connect parts from any raw material, therefore, special compositions should be purchased.

- Financial expenses. It is necessary to calculate the acceptable cost of the glue based on your capabilities. For some jobs, it is not at all necessary to buy the most expensive adhesives, because a cheaper analogue can also successfully cope with finishing and repairs.

- When the user decides on a specific brand of glue, then you need to remember to read the reviews about its manufacturer - this will help to make sure of the peculiarities of using the material, learn some secrets of use and, in some cases, protect yourself from purchasing low-quality products.

Advice

To make the use of two-component adhesive in various fields easy and effective, it is necessary to heed the recommendations of professionals in construction and renovation work and experienced users.

The advice of professionals will help to facilitate the process of working with glue.

- The polymerization process is not clearly fixed in time. It can be influenced in various ways. If it is necessary to speed up the procedure, it is recommended to increase the ambient temperature.Some craftsmen prefer to add hardener in large proportions to speed up the process. If you need to prolong the process, then it is worth adding less hardener than indicated in the instructions.

- If parquet is laid on the two-component connector, it is recommended to wait for complete drying not 24, but 48 hours.

- Do not forget about protective equipment when working with epoxy two-component adhesive. These include gloves, a bandage for respiratory protection. It is necessary at the stage of mixing the components, since at this stage the release of harmful substances can occur. Gloves come in handy to keep the glue from getting on your hands, as it can be difficult to clean.

- If during the repair process the two-component glue gets on the skin, then an acetone solution will help to wash away its traces.

- Drafts in the room should be avoided when working with this adhesive.

- If a floor mortar is used, the surface to be applied must be dry, but not too smooth.

- Some formulations have very fast adhesion, so it is recommended to use them in conjunction with other substances when it is necessary to equip any finishing details without haste.

- The tools used to mix or apply the two-component adhesive should be thoroughly cleaned. If the equipment is not cleared of contamination in time, it may become unusable.

Two-component adhesives are a truly unique bonding agent for various coatings and parts. If you take into account all the nuances of choosing and working with such material, then you can easily cope with repair and household difficulties.

For the use of Hosch two-component German structural adhesive, see the following video.

The comment was sent successfully.