What is polystyrene foam glue and how to choose the right option?

When finishing surfaces, the quality of the material is of paramount importance. But in addition to the characteristics of the facing raw materials, the method of fixing it is also important. For example, if we are talking about expanded polystyrene, it is worth thinking about the correct choice of adhesive composition for fixing it.

Features of material installation

For the insulation of facades and interior work, many different construction products are used. One of these products is polystyrene foam. The material is made up of slabs of various dimensions and thicknesses. For fixing the slabs to various substrates, including concrete and metal, specialized adhesives are purchased.

The main task of the glue for expanded polystyrene is the presence of properties that ensure high-quality fastening of the material to the surface.

Both domestic and foreign companies are manufacturers of such products. Allocate funds for outdoor and indoor work.

According to experts, when choosing an adhesive for mounting a material, it is necessary to pay attention to several main points.

- The main task of adhesives is to ensure reliable adhesion of the slabs to the base, so the price of products in this case plays a secondary role.

- Adhesive solutions or mixtures (especially products intended for outdoor use) must be resistant to temperature fluctuations, precipitation and other negative environmental influences.

- The environmental friendliness of the compositions plays an important role. If you do not pay attention to this nuance when buying a composition for interior decoration, the product can negatively affect the health of people in the room.

- Ease of installation is also a significant nuance.

As practice shows, not all goods presented on supermarket shelves meet the above requirements. Because of this, the process of installing polystyrene foam is often complicated.

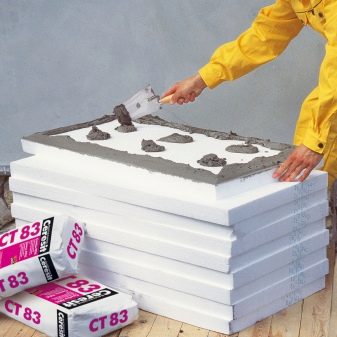

There is a certain specificity of working with glue for outdoor finishing work. As for the bituminous and cement mortar, the compositions should be applied in a permanent layer to the surface of the slab. The base of the wall, in turn, must be prepared so that the product can be glued as tightly as possible. To do this, it is cleaned of dirt and primed.

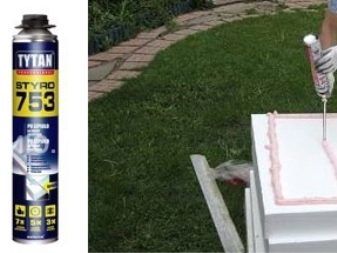

If it is planned to install polystyrene foam using glue-foam, the composition is applied along the perimeter of the product, as well as in the center in a zigzag. After that, the slab is fixed to the surface.

If excess solution is formed, they are carefully removed after the glue has set. If the material dries for a very long time, it is better to fix the plates with props.

Overview of adhesives

Adhesives for indoor and outdoor use differ in composition and characteristics. They can also have a different consistency, be sold as a dry or ready-to-use mixture. The only property that all types of glue have in common is the prohibition on the inclusion of any solvents. Contact of gasoline or acetone with the insulation is unacceptable, because these substances can burn through it.

As for glue-foam, this type of product is very convenient for use due to its ease of application.The finished composition includes all the necessary components that allow you to quickly and efficiently glue the products. However, it should be borne in mind that this glue dries very quickly. It is used most often as a single-use product.

Dry formulations allow you to use them several times, mixing the mixture in portions, as needed.

Experts advise to give preference to dry products when the working surface has defects and irregularities.

Adhesive foam for outdoor use has a polyurethane base and is sold in cans, which simplifies the application of the composition to the sheets of material. Unlike bituminous products, it dries quickly, so there is no need for material supports. The tool is gaining strength after a couple of hours.

As for the popular brands of adhesives for outdoor use, we can mention the products of the companies Ceresit, Berg and Knauf. These brands have already won the trust of customers due to their high quality products.

Adhesives designed for working with polystyrene foam plates can be divided into two types:

- dry products;

- polyurethane solutions.

The differences between these groups lie in the method of breeding, packaging, appearance, and also the technique of processing the material.

In addition, Styrofoam products can be categorized into split formulations and general purpose products. The latter type has a wider range of applications. Such compositions can not only perform basic functions, but also serve as a means for reinforcing slabs with a mesh. Their disadvantages include average quality characteristics. However, this disadvantage justifies the affordable cost of the product. For a more reliable installation, it is worth giving preference to adhesive solutions or mixtures of a narrow spectrum of action.

For outdoor work

The most suitable composition for external work with expanded polystyrene plates can be considered bituminous gluedespite the fact that it contains a solvent. This component does not pose any danger to the insulation. The products are sold ready-to-use. To glue the surfaces together, bituminous glue must be applied to the wall.

The next popular type is cement gluewhich is perfect for working with brick subfloors, concrete and cinder block walls, as well as for fixing ceiling tiles. Typically, such a mixture is sold dry, and for preparation, the powder is diluted with water. The disadvantages of dry products include the fact that it takes some time to dilute the glue to the desired consistency. However, the cement-polymer composition and low cost make the product very popular. It is suitable for those cases when extruded polystyrene foam is used as insulation.

In room

When installing polystyrene foam boards indoors, it is necessary to use compounds that meet the following requirements:

- high level of adhesion;

- lack of toxic substances in the composition;

- resistance to temperature fluctuations;

- quick installation and minimal smudges.

In apartments and houses with a constant positive air temperature and minimum humidity, the slabs can be glued to the surface with glue PVA... In rooms where the humidity is high enough, it is better to use glue rubber-based... Such products are excellent for working with metal, plastic, concrete, wood and ceramics.

Dry gypsum mix can be used for surfaces with base defects. This group includes Knauf Perflix glue. This is a completely natural product that is intended for indoor use only.

When working with decorative elements and ceiling surfaces, it is worth stopping the choice on water-soluble formulations... Such products are white, so they can hide as much as possible all existing seams and joints between sheets of material.

Foam adhesive can be used for basements, balconies, walls and floors. It should be applied at temperatures from 0 to +35 C.

Characteristics and consumption

According to experts, the most economical composition in terms of product consumption is polyurethane foam and paintable glue for outdoor use.

To calculate the estimated consumption of the adhesive, you need to have an idea of the average amount of its consumption. This value directly depends on the product, its type, and manufacturing technology.

On average, dry powders have a consumption of about 500 grams per 1 m2 of material. For a bituminous mixture, this figure ranges from 800 grams or more per 1 m2. Polyurethane adhesives are remarkable in that they have the lowest consumption - 1 can is usually enough for 10 m2.

Selection Tips

Going to the supermarket for glue for repair work, you should take into account the following important nuances associated with the choice of a product:

- quality products should not be tough;

- the vapor permeability of the composition should have an average indicator;

- as for density, preference should be given to the most durable formulations, this saves on product consumption;

- during outdoor work, the stability of the solution to negative temperatures is of particular importance;

- Each manufacturer sets its own price for products, so it is not safe to say that cheaper products are of lower quality.

What else can you glue?

- Among the variety of adhesives suitable for polystyrene foam, one can single out styrofoam adhesivewhich is also used for polyurethane and polystyrene mounting. Among the positive features of the product, one can note the reliable fixation of the material to concrete, plaster and most wood-containing substrates. The products have a wide range of applications, therefore they are allowed to work both indoors and outdoors. In addition, after complete drying, the material can be additionally treated with dyes or varnish.

- A reliable adhesive composition provides good fixation of raw materials, however, some craftsmen use improvised means in working with expanded polystyrene, for example, liquid nails or tile mastics... Often, silicone sealant is used for mounting the material. However, when choosing such compositions, people do not take into account the fact that such solutions most often corrode the material.

- For sticking raw materials to a small surface sometimes you can use double-sided tape... But this method allows you to fix the material well only if the base is small. Otherwise, this installation option should not be considered.

For information on how to properly apply glue-foam using TechnoNICOL as an example, see the next video.

The comment was sent successfully.