Block adhesive: selection criteria

Block glue is a mixture of several components designed for joining building block parts. The use of such a composition facilitates the task of erecting internal walls and partitions, especially from lightweight slabs and structures made of aerated and foam concrete.

Peculiarities

Glue is a chemical composition that provides adhesion of various materials to each other. If earlier the walls were erected mainly from bricks and its analogues, today the usual methods of construction are recognized as excessively laborious, including due to the high cost of the material.

Lightweight building blocks have become the preferred material today, significantly replacing traditional bricks. Small in size and easy to use, they are connected using adhesive mixtures. For block structures, specialists develop numerous adhesives and foams for joining in the process of erecting building walls.

The obvious fact is that the quality of individual components completely determines all the performance characteristics of the adhesive. As a rule, in its production, various brands of cement, sand, organic and other plasticizers are used. The composition of the mounting glue depends on which blocks need to be connected together.

The most common in the production process - a cement-sand composition cannot be prepared on our own, when mixing, special technologies are used. Therefore, the mixture is produced in bags, weighing up to 20-25 kg.

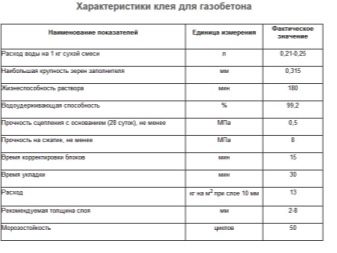

Specifications

There are only two types of adhesive mounting mixture on sale.

- For winter and temperatures not lower than +5 degrees Celsius. Winter formulations can be used at any time of the year, including summer. At the same time, the limit of their frost resistance is still limited to -15 degrees, it is better not to carry out installation work in more severe frosts.

- If you have a second variety (summer), then the mixture is not suitable for a cold pore, there will be a rapid cracking of the layer. The warmest type of adhesive is polyurethane foam for wall panels and block structures with ridges and grooves. It provides additional waterproofing and reduces thermal conductivity.

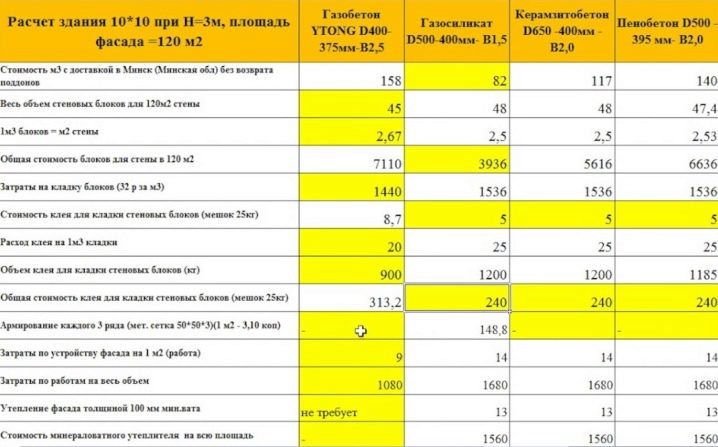

Consumption

In practice, this is often not the case. Much depends on how strong the curvature of the surfaces is. The higher it is, the more layers are required. In this case, weather conditions are an important factor.

Taking into account all the nuances, on average, a cube of building blocks requires one bag of mixture, that is, 25-30 kg. And sometimes it can take up to 36 kg of adhesive. Therefore, in the absence of a lot of experience in laying, it is better to purchase mixtures with a margin.

For durable bonding of porous structures with cells, more moisture is needed, so the consumption of adhesive per 1 m2 will be higher. To minimize all costs, calculate how much glue is needed to lay the cube of foam blocks. For example, for aerated concrete, the standards provide for the consumption of no more than one and a half kilograms of glue per 1 m3. In this case, the seam is extremely thin - no more than 1 mm. However, for this, the surface must be perfectly flat.

The main advantage of the glue is considered to be profitability with high efficiency and reliability of the connection. The amount of cement and sand mortar applied to the blocks should create a layer equal to 2-3 cm in height.At the same time, such an adhesive mixture firmly connects the elements with a thickness of the composition already starting from one and a half centimeters. If glue is used, builders bypass seams starting at 4-5 mm in thickness.

Using the most modern styling technologies, specialists achieve thin seams, just one or two millimeters. With this type of connection of blocks, the cold in the room does not linger, fungus and mold will never appear.

Manufacturers overview

Among the manufacturers of dry mixes in demand on the market, offered at the lowest prices, it is worth mentioning the companies Zabudova and Eunice Uniblock... The mixtures are suitable for laying gas silicate blocks, from which low-rise structures of modern buildings are mostly erected. They consist of sand and cement, but a mixture of this quality cannot be obtained on our own without special equipment.

In addition to them, for gas silicate blocks, experts recommend using adhesives of brands "Prestige", "Bonolit" and "Pobedit-160".

Firm Volma produces assembly adhesive that is easily diluted with water and is suitable for use within an hour. The advantages of the composition are in its versatility, it is applied to tongue-and-groove blocks and slabs, cement bases and plaster, foam and aerated concrete blocks, gypsum-fiber structures. Before use, preparation is needed: irregularities are removed, metal surfaces are protected from corrosion and cleaned. The mixture is based on gypsum with mineral additives. Gives a durable and thin layer, moisture resistant.

Company "Rusean" produces several types of composition: ordinary glue for cellular blocks made of polystyrene concrete and an assembly mixture based on gypsum for joining tongue-and-groove and gypsum fiber boards. The popularity of the manufacturer is explained by the inexpensive price of a bag of glue mixture - about one and a half hundred rubles.

Firm Bolars - the Russian leader in the production of professional building materials. Its products are standard composition adhesives and primers for granite and assembly mixtures. If you need a good glue for winter, then you should pay attention to the products of the Bolars company. Frost-resistant adhesive works well at temperatures down to -12 degrees Celsius.

In addition, you can offer several more types of building mixtures.

- Universal adhesive Cbs for any lightweight concrete blocks. Demonstrates excellent compressive strength, does not freeze within three hours, and is given 7 minutes to adjust products.

- "Aerated concrete"... Applied at a temperature not lower than + 50 ° C. In this case, the required seam thickness is from 3 mm to one centimeter.

- "Polystyrene G-32". An example of a sand-cement mixture with additives. Provides weather resistance, is not subject to biological influences. When applied, a layer of 2 to 8 mm is applied.

How to choose?

Several types of lightweight blocks and slabs are used in modern construction.

- Expanded clay concrete, ceramic (building elements that in appearance resemble bricks with voids inside, they are made of fired clay).

- Concrete, polystyrene concrete and foam concrete. Housing made from such materials is not warm enough, so clean concrete is not suitable for laying walls. But for buildings on the farm and summer premises, these blocks are perfect.

- Gas silicate, cellular materials. Silicate blocks are among the most demanded building materials.

- Gypsum tongue-and-groove blocks or slabs. They are parallelepipeds with grooves and ridges on the sides for interconnection, made of gypsum binder.

If masonry glue is used for foam blocks, crushed white quartz sand is added to the main components of the mixture during manufacture. The ready-to-use composition can be stored for no more than 2-3 hours.All the crushed components of such an adhesive make it possible to firmly connect the elements, while the layer necessary for gluing remains thin and at the same time strong and plastic.

This composition is characterized by frost resistance, it is classified as winter, it is considered good for installation at low temperatures.

Ceramic blocks are glued using mixtures of similar composition, prepared from imported organics based on cement and sand. The ceramic adhesive is water-repellent. Applies evenly and adheres firmly to blocks during construction.

If we are talking about polystyrene concrete, then for reliable adhesion, a mineral composition with Portland cement is needed. Capsular polystyrene is added to it, subjecting it to preliminary foaming. The adhesive is characterized by a porous structure, provides resistance to decay and has excellent thermal insulation properties.

Universal glue firmly connects the structure of wood concrete and glass elements. It is an expensive mixture of imported ingredients that can be used both in summer and in cold weather. Such glue is moisture resistant, not afraid of frost, has sufficient plasticity. It is made from environmentally friendly components, does not freeze within 10-15 minutes.

For frameless installation of tongue-and-groove plates, a mixture based on gypsum, combined with additives from mineral and chemical raw materials, is produced. The adhesive is characterized by a high degree of adhesion, it is applied directly to both vertical and horizontal joint grooves. Some types bond together concrete and brick, gypsum fiber sheets and granite.

The modern type of adhesive is foam for cellular blocks. It is also used for all types of bricks and gas silicates. Durability has not yet been tested by time, but high adhesion is achieved within a few hours. Foam blocks are laid in a warm room.

Tips & Tricks

- Dilute the composition exactly according to the instructions, which must be read carefully. Dry mixes are added to water, not vice versa. In this case, you will need a drill with a special attachment.

- Mix the composition exclusively from a dry mixture, do not use excess material. The bag indicates what is the volume fraction of the granular substance, at what temperature to dilute the glue, what layer thickness is optimal for a given composition, etc.

- Keep the composition homogeneous and mix all ingredients thoroughly. Stir the mixture periodically.

- The temperature regime needs to be constant, the drops affect the quality of the resulting mixture.

- If you use a notched trowel when applying, the glue consumption can be reduced by 20-30%.

Experts recommend purchasing both blocks and an adhesive mixture at once. In this case, it is best to accurately calculate the required amount in advance. It is difficult to assess the quality of the adhesive material, for this it is easier to buy a small amount of different compounds, dilute according to the instructions and compare.

The main criterion will be the weight of the composition solidified to a solid state. The lightest glue is considered to be the best. In this case, the degree of thermal conductivity will be minimal.

To assess the strength of the connection, it is enough to glue two blocks, wait for the right time, and then throw them down with a sharp movement. If, when falling to the ground, the seam does not hold, and the blocks parted, this glue does not suit you for adhesion. If the seam is preserved, you can count on high quality bonding in the future.

See the next video for more details.

The comment was sent successfully.