How long does polyurethane foam dry?

Construction without polyurethane foam is impossible. Its dense composition will seal any surfaces, provide sound and thermal insulation in all hard-to-reach places. However, many are interested in how long polyurethane foam hardens. To find out, you need to carefully study the properties of the product, technical characteristics, list the main types of polyurethane foam.

Properties and types

Polyurethane foam is a one-component polyurethane sealant. Its popularity is enormous: without it, the process of installing doors and windows becomes much more complicated, it becomes impossible to carry out professional work directly related to repairs. The use of such a sealant does not require the purchase of secondary tools for work. The liquid material enters all the necessary cavities, after a certain amount of time it dries completely. Polyurethane foam is always supplied in the form of cylinders containing a liquid prepolymer and a propellant.

When the contents of the cylinders are released, the polymers react. The humidity of the air and the sealed bases is responsible for their release.

Technical specifications

To find out how long it takes to completely dry the polyurethane foam, should be said about the characteristics:

- Primary expansion is the property by which the volume of foam applied to the surface increases. Due to this property, the material takes up space completely and fixes it securely.

- Consider a secondary extension. Since the foam must increase or decrease in volume, this characteristic is negative. As a rule, this is due to improper use (the temperature regime is exceeded, the base is not cleaned, mechanical stress has been made).

- The curing time for the polyurethane foam varies. The top layer dries in literally 20 minutes, full set takes place in a day. In this case, excess material is allowed to be cut off after 4 hours from the moment of application.

- As practice shows, polyurethane foam adheres perfectly to structures made of wood, concrete, metal, plastic, stone and glass. Silicone and polyethylene are incompatible with polyurethane foam.

- An indicator of temperature stability is important (the ability to withstand certain temperature changes). For example, the foam of the Macroflex company can withstand the temperature range from -55 to +90 degrees. Note that its flammability is completely reduced to zero - the foam does not burn.

- The foam material involves interaction with chemicals, the ingress of ultraviolet rays leads to darkening and destruction of its base. Therefore it is necessary to apply a protective layer (any paint or primer).

Expansion ratio

Rapid and at the same time multiple expansion of the composition is the main task of the sealant. As a rule, the volume increases by 60% when using household polyurethane foam. The professional variety is distinguished by a more pronounced coefficient (two or three times). The increase in the material depends on the conditions of its use.

Polymer expansion depends on temperature, air humidity, the rate of release of the foam composition from the container, as well as from surface treatment before direct application. Usually, information about the maximum possible output volume is contained on the cylinders themselves, but it is not recommended to completely trust the declared indicator.

Often, manufacturers deliberately embellish the capabilities of their product: they proceed from the calculation of the ideal conditions for applying the foam.

Let's touch on the foam expansion process. It is customary to divide it into two stages: primary and secondary expansion. The primary is provided a few seconds after release. The second stage is the final hardening followed by polymer transformation. The foam gets its final volume already at the initial stage. In the second, as a rule, there is an expansion up to 30%. Therefore, we advise you not to neglect the second stage.

It is important to remember that polyurethane foam not only implies expansion, but also shrinkage after release. Buying from well-known manufacturers quite often ensures the quality of the building material (shrinkage is not higher than 5%). If shrinkage is outside this level, this is evidence of poor quality. Excessive shrinkage leads to polymer tearing, and this is often the cause of new problems in construction.

Views

In specialized stores, there are professional and household types of polyurethane foam:

- Professional foam assumes the presence of a special gun for application (the cylinder contains the necessary valve). At the same time, the gun has a decent price, usually 10 times higher than the cost of the foam itself, because it is designed for multiple use.

- Household sealant applied without auxiliary tools. For application, you need a small plastic tube that comes with the balloon.

According to the temperature threshold, it is divided into summer, winter, all-season:

- A variety for the summer season is applied at temperatures from +50 to +350 degrees. In such temperature conditions, it freezes.

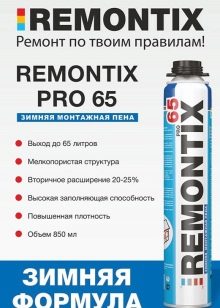

- Winter foam - from -180 to +350 degrees. The volume of the applied composition directly depends on the temperature drop.

- The variety, universal for all seasons, has the combined characteristics of both of the above options. This is a great cold interaction, huge release and fast solidification.

Scope of application

Below are some types of work where it is necessary to use polyurethane foam:

- filling voids and cracks in rooms where there is no heating, as well as on the roof;

- elimination of gaps between doors;

- fixation without fastening tools;

- fastening thermal insulation to walls;

- sound insulation;

- application in the field of premises renovation;

- sealing of holes on the surfaces of boats, rafts.

Polyurethane foam allows filling seams and gaps with a width of up to 80 mm inclusive (larger gaps must be pre-filled with boards or bricks). In order for the sealant to last as long as possible, it is necessary to use it correctly.

Below are some tips for using and applying polyurethane foam:

- It should be sprayed with water on the surface for better adhesion (before and after application).

- It is necessary to shake the cylinder before starting work, holding it with the bottom up.

- Filling of any gap should not be carried out completely (by about half) - this will reduce the consumption of the composition.

- It is necessary to cut off excess foam after the polymerization process.

- It is preferable to use high quality and proven products of well-known brands.

Consumption

Most often, a cylinder volume of 750 mm has a discharge of 50 liters of material. However, this does not mean that it will be enough to fill a 50 liter container. Generally, foam is unstable due to internal bubbles. Due to its own weight, the lower layers burst, and this, in turn, significantly reduces the volume. So 50 liters is a conditional figure. Using the material in the cold, you can face a clear decrease in volume. Therefore, the information indicated on the surface of the cylinder is true only when maintaining ideal conditions. The hardening time varies: the composition dries differently if it is used in the apartment and on the street.

For the secrets of polyurethane foam, see below.

The comment was sent successfully.