Profflex polyurethane foam: pros and cons

The need for polyurethane foam arises during repair and construction work, installation of windows, doors, all kinds of seals. It is also used in the process of warming rooms, even fastening drywall can be done with foam. Recently, foam is often used in the manufacture of decorative landscape details, elements for car tuning.

During sound and heat insulation works, polyurethane foam is needed, which is presented on the market in a wide range. Many people know Profflex foam and its types. Polyurethane foam Firestop 65, Fire-Block and Pro Red Plus winter, its properties, manufacturer reviews will be discussed in this article.

Peculiarities

Polyurethane foam is a polyurethane foam sealant, which contains both basic and auxiliary substances. The main components are isocyanate and polyol (alcohol). The auxiliary components are: blowing agent, stabilizers, catalysts. It is produced, as a rule, in aerosol cans.

Profflex is a Russian company engaged in the production of polyurethane foam. The quality of the material meets all European standards. The Profflex product line includes many types of polyurethane foam, which are widely used by professional builders and people who make repairs on their own.

Advantages and disadvantages

Any building material has its own advantages and disadvantages, therefore, before buying foam, you need to familiarize yourself with all its properties and characteristics, study all the pros and cons of the material.

Profflex polyurethane foam has the following advantages:

- a high degree of adhesion (the foam can be used when working with coatings of stone, metal, concrete, wood, plastic and glass);

- fire resistance (foam does not conduct electricity);

- durability;

- fast setting time (the material dries completely in 3-4 hours);

- lack of a poisonous smell;

- affordable price segment;

- low porosity;

- high degree of sound / heat insulation;

- increased water resistance;

- ease of use.

If we talk about the shortcomings, then these include:

- Lack of UV protection. Under the influence of sunlight, the foam changes color - it darkens, it also becomes fragile.

- Fear of changes in temperature and humidity.

- Harmful to human skin, therefore it is necessary to work with the material only with protective gloves.

Analyzing all the pros and cons of a building material, it is worth noting that the material is endowed with many advantages, so you can use it without fear of negative consequences.

Views

The entire range of Profflex polyurethane foam is divided into two types: professional and household sealant. You need to choose one or another type depending on how much work is to be done using this material.

Polyurethane foam can be divided into types according to several characteristics.

- Composition. The mounting material can be one-piece or two-piece.

- Temperature conditions. Foam is produced for use in summer (summer), winter (winter) or all year round (all-season).

- Application method. Professional installation material is used with a pistol, while household material is equipped with a self-contained valve and a direction tube.

- Flammability class. Foam can be combustible, refractory or completely flame retardant.

The most important is the temperature regime, since both the consumption of the composition and the quality of work depend on this.

The main difference between winter foam and summer foam is that there are special additives in winter assembly materials that help to increase the polymerization rate of the composition at negative and zero temperatures.

Each type of installation material has its own characteristics, its own scope and composition. To understand what type of foam is needed, you need to familiarize yourself in detail with the features of the main categories of Profflex materials.

Polyurethane foam Firestop 65 is a professional, one-component sealant with the following properties:

- fire resistance;

- foam output within 65 liters. (it depends on the temperature and degree of humidity of the air in the environment where the mounting material is used);

- hardening at a temperature of -18 to +40 degrees;

- preservation of all characteristics at a low degree of humidity;

- high heat and sound insulation;

- increased adhesion (foam adheres well to gypsum, concrete, brick, glass, PVC, wood);

- skin formation within 10 minutes.

The mounting material is not used on polyethylene, teflon coatings, polypropylene.

Scope of this mounting material:

- installation of windows, doors;

- thermal insulation of water pipes, sewer, heating networks;

- insulation works of wall panels, tiles;

- sealing of various building partitions, car cabins;

- frame construction using wooden parts;

- insulation of roofs.

Before use, you must read the instructions.

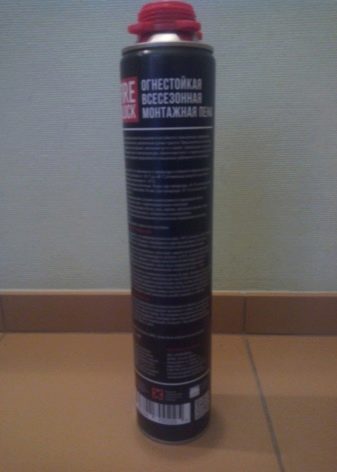

Polyurethane foam Fire block is a professional sealant belonging to the category of one-component, fire-fighting materials. It is used in rooms where there are high requirements for fire safety. Fireblock foam belongs to all-season mounting materials and is used at low temperatures without changing its properties.

She is endowed with the following properties:

- fire resistance (4 hours);

- hardening at temperatures from -18 to +35 degrees;

- resistance to low humidity;

- increased degree of sound and heat insulation;

- good adhesion to concrete, brick, plaster, glass and wood;

- low moisture absorption;

- skin formation within 10 minutes;

- the presence of a combustion retarder;

- resistance to acids and alkalis;

- plastering and painting are allowed.

It is used for thermal insulation works, when filling through gaps, when installing doors and windows, when installing fire doors, partitions.

Polyurethane foam Pro Red Plus winter - one-component, polyurethane material, which is used at temperatures from -18 to +35 degrees. Optimum retention of properties is achieved at -10 degrees and below. The material is moisture resistant, has high heat and sound insulation properties, adheres perfectly to concrete, glass, brick, wood and plaster. The film forms in 10 minutes, the composition contains a combustion retarder, and the processing takes 45 minutes. Most often it is used when sealing joints, cracks, and when installing window and door frames.

Assembly sealant Storm Gun 70 has a special formula that provides increased foam output - about 70 liters from one cylinder. For use by professionals only.

Mounting material is widely used:

- when filling voids;

- when eliminating seams, cracks in joints;

- when installing door and window frames;

- while providing heat and sound insulation.

The sealant hardens at temperatures from -18 to +35 degrees, is not afraid of low humidity, has a high degree of adhesion to many surfaces. The composition contains a combustion retarder. The foam is ozone-safe, its solidification time is from 4 to 12 hours.

The assortment of Profflex polyurethane foam includes materials from the Gold series, which are intended for use in winter and summer. There are also sealants labeled station wagon that are all season. Foam is produced in cans of 750, 850 ml.

Reviews

Profflex is a reliable, domestic manufacturer of installation materials, which has received positive reviews both among professional builders and among people doing installation work on their own.

Buyers prefer this building material for various reasons, but this is mainly due to the fact that Profflex polyurethane foam has:

- wide temperature range of application;

- economical consumption of material;

- long shelf life.

This type of installation material can be purchased at any hardware store, as well as on specialized sites.

Application Tips

Each type of Profflex polyurethane foam has its own instructions for use, but also there is a list of rules that must be followed while using this material.

- Use foam according to the weather season. Summer foam for summer, winter foam for winter.

- It is worth paying attention to the temperature of the foam cylinder, which should be between 18 and 20 degrees above zero. If the cylinder is cold, then it should be slightly warmed up. To do this, it must be lowered into a container of hot water. Always shake well before use.

- Before using the sealant, the surfaces to be covered with the compound should be thoroughly cleaned of dust, degreased and sprinkled with water, especially in summer.

- Work with the material in protective clothing.

- When using, the foam cylinder should be in an upright position, and filling of cracks, seams should be done by 70%, since the foam tends to expand. For large cracks, a multi-layer filling should be done - first the first layer, then drying is expected and the next layer is applied.

- Full polymerization of the material occurs throughout the day, and in winter, it can take a longer time. This should be taken into account in further construction work.

- When working with a sealant, it is easier to use a nailer than the tubing that comes with the material.

- After complete drying, the residues are removed mechanically. For cutting, you can use a sharp knife or a metal saw.

If the foam gets on your hands or clothes, you need to use special solvents to remove it.

If you use the installation material, adhering to the basic rules, then with its help you can eliminate cracks and holes of any size, including ceiling defects.

You can watch the comparative testing of Profflex polyurethane foam in the following video.

The comment was sent successfully.