Polyurethane foam: types and specifications

When preparing for the cold season, it is important to think about insulating your home. Polyurethane polyurethane foam will help to cope with such an important task without significant costs.

Peculiarities

The polyurethane foam mixture consists of highly concentrated hydrogen-oxygen and low-weight liquid components. The base material is a polyol or polyisocyanate. The composition of the foam also includes a propane-butane mixture, substances that accelerate chemical processes. The color of the mixture has a yellowish tint, which can become darker in the sun. Additional components differ depending on the conditions of its use.

The composition is available in convenient aerosol barrels, a quarter filled with pressurized gas. This makes it possible to carry out heat-insulating repairs, for example, filling joints or seams in a short period of time.

The principle of operation is based on the interaction of a substance with humid air. First, the substance expands, and then hardens with the formation of polyurethane foam. Its ability to expand in volume allows it to tightly fill any openings, thereby providing reliable thermal insulation. After the foam has hardened, wallpaper can be glued to it or plaster or putty can be applied.

Views

There are two types of polyurethane foam: one-component and two-component.

- One-component the mixture differs in that when it is used, the surface needs to be moistened. The composition gives a large primary expansion, in some cases there is a secondary expansion.

- Two-component the mixture does not require wetting the surface. The material has a long service life, high density, and is also characterized by minimal secondary expansion.

The substance is sold in two versions.

- In cylinders. The sealant is applied using a standard tube, does not require additional tools, and is easy to use. This option is the most economical, used in everyday life.

- In pistols. The sealant is applied with a pistol. The professional method of use ensures high processing accuracy and also helps to reduce volumetric expansion. The material hardens in a shorter period of time.

Mounting glue is produced by:

- for the winter period;

- for the summer period;

- off-season.

It should be remembered that for each period there is a range of permissible temperatures, which are indicated in the instructions for use.

Manufacturers

Today, polyurethane foam from various well-known manufacturers is on sale.

- Soudal company. The products are characterized by high quality, a wide selection of formulations that allow the use of foam under various environmental conditions, at an affordable price. All this is ensured thanks to innovative technologies actively introduced into the production of the material.

- Dr. Schenk. The company manufactures products characterized by high quality standards and affordable prices. There is a wide selection of different formulations on the market for both domestic and professional use.

- Kim Tec. The products of this company have reliability and quality. Compositions are available for use at various temperature conditions. There are options for home or professional use.

- Profflex. The products of the Russian company are characterized by high quality. Compositions for professional, household use, as well as special mixtures are produced. The line is represented by mixtures adapted to various temperature conditions, with fire resistance, good adhesive properties.

Specifications

Polyurethane foam has a number of important properties that make it indispensable in many cases. Knowledge of the characteristics of the material allows you to achieve the best result.

Polyurethane foam is characterized by:

- good sound insulation;

- reliable thermal insulation;

- density;

- strength;

- long service life;

- good adhesion;

- fast solidification;

- fire resistance;

- conductivity;

- immune to mold;

- good tolerance to changing temperature conditions;

- environmental friendliness;

- security;

- ease of use.

It should be remembered that waterproof foam must be protected from UV rays, as they tend to degrade the material in a short period of time. Therefore, the foam is covered with paint, plaster, putty. It should be noted here that polyurethane does not bond well with silicone, polyethylene, Teflon.

Since the mixture absorbs liquid well, it must be protected from moisture. This is done with waterproofing materials. It should also be remembered that after hardening, the substance may be colored.

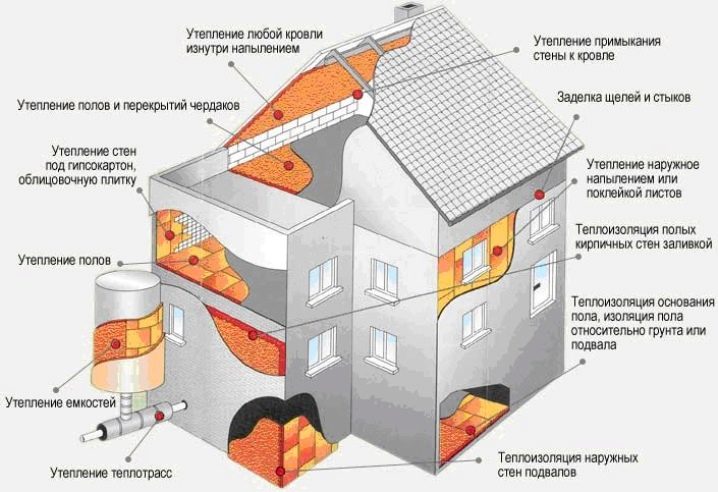

Scope of application

The main purpose of the foam is to fill voids, joints, cracks in already mounted structures. It is used for both indoor and outdoor work.

Polyurethane is used:

- when installing windows, insulating frames;

- for insulation of premises, including balconies;

- for roof insulation;

- as an increase in the thermal insulation properties of the floor, foundation;

- when insulating partitions, doors;

- to increase the insulation of heating and water supply systems;

- in the production of furniture, household appliances;

- for fixing wall panels;

- for gluing surfaces;

- for fixing insulating materials such as foam;

- to reduce noise during the operation of air conditioners, heating systems;

- for sealing cavities between pipelines, joints of hoods, split systems;

- in the manufacture of decorative figures;

- polyurethane is part of synthetic fabrics such as spandex, lycra.

With the help of the assembly mixture, surfaces consisting of glass, metal, wood, stone or concrete can be insulated.

Subtleties of use

The sealant is used to insulate a room by filling gaps. The size of the cavities can range from 1 to 8 cm in diameter.

The foam should be applied to the surface in a systematic manner, avoiding sudden movements, while maintaining a constant speed. Before work, the base must be cleaned of dirt, foreign particles, treated with water.

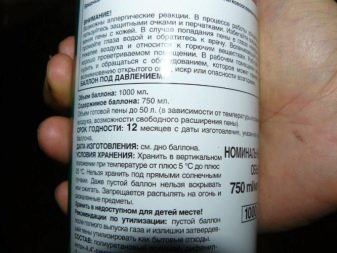

Shake the can before applying the sealant. It is important to consider the fact that foam expands as it cures. Therefore, the amount of material used must be calculated as accurately as possible.

When applying the foam, the can must be held upside down. Work on the insulation of vertical surfaces is carried out in the direction from the bottom up. Complete solidification of the material occurs after about 8 hours. Until the final drying of the substance, it is not recommended to touch it with your hands.

All work must be carried out in protective equipment. To prevent the substance from getting into the eyes, special glasses are used. Gloves are used to protect hands. In case of accidental contact with the skin or mucous membranes, rinse the surface with copious amounts of water.

Consequences if the instructions for use are not followed

With unprofessional use, you may encounter such problems as:

- too much shrinkage;

- the appearance of bubbles;

- spreading of matter over the surface;

- the complexity of laying the material;

- wet rod.

These reasons often arise due to non-compliance with the temperature regime, the presence of low-quality components in the foam. The characteristics of the substances that are used to accelerate the hardening time can adversely affect. An unprepared base will also interfere with obtaining a quality surface.

It is necessary to monitor the temperature of the cylinder itself, since heating it to 50 degrees can lead to an explosion.

Before carrying out repair work on the insulation of the room on your own, you must carefully study the instructions for use, and also test a small amount of the substance in a small area.

If you have any questions, you should consult with professionals or entrust all the work to them. This will help you get the desired result in a shorter time.

Selection Tips

When buying a sealant, you should pay attention to the release date of the product, as well as external parameters, for example, weight, package tightness. It should be remembered that the shelf life can be from one to one and a half years. The balloon weighs about 900 grams.

The foam should be chosen according to the season. You can choose an option for use in the summer, winter, or purchase an all-season foam.

It should be noted that the summer season includes air temperatures from 5 degrees above zero. At the same time, the temperature of the cartridge itself must be at least 10 degrees above zero. In the cold season, special compositions are used to increase the solidification rate of the material. When choosing a foam for an off-season type, remember that it can be used at a temperature of at least minus 10 degrees. The temperature of the cylinder itself must be at least 5 degrees above zero.

One of the quality criteria of the composition is the absence of foam dripping from vertical surfaces. When solidifying, it is necessary to pay attention to the structure of the substance. The smaller the dimples, the higher the strength properties, moisture resistance, and adhesive properties.

How to use polyurethane foam correctly, see below.

The comment was sent successfully.