Fireproof foam Makroflex FR77: features and characteristics

When building new or renovating old houses, there is always a question of safety, including fire safety. Each tenant wants to know that in case of emergency he will have the opportunity to save himself and help his loved ones. Therefore, this issue should be worked out by builders at the very early stages of work, because they are responsible for the reliability and safety of the building.

The use of refractory materials is often impossible due to their high cost. However, there are also more affordable means. One of them is Makroflex FR77 fire resistant foam. This article will tell you about the features and characteristics of this product.

Description

Makroflex FR77 is a professional one-piece construction material. The product is sold in cylinders with a gun, prepared in advance for work. The volume of the package is 750 ml. The product complies with European standards, which are regulated by ISO 9001 / EN 29001.

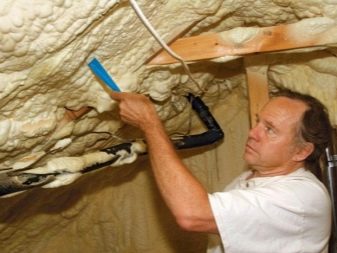

The foam is intended for filling gaps and voids in the gaps between mineral and metal layers during the construction of buildings with specific fire safety requirements and evacuation times in case of fire.

The product hardens when exposed to moisture.

Properties

The main property of the product is increased fire resistance. When applied correctly, it is fire resistant and does not sustain combustion for four hours. Also, this foam has excellent heat and sound insulation parameters.

Makroflex FR77 adheres to all building materials. The exceptions are silicone, oils and greases (the foam simply drips off of them). Therefore, one of the conditions for preparing for work is the removal of such substances from the surface.

Foam can only be used at freezing temperatures. It should be stored in a dark room at a positive temperature, protecting the product from sunlight. Even short-term storage of the product at sub-zero temperatures is not recommended. After this, the properties of the foam may noticeably deteriorate, which in this case is unacceptable.

Cylinders should not be heated to high temperatures. If the cylinder is hot, it must not be shaken to avoid an explosion. It is better to gently dip the product in cold water for a while. After cooling, the cylinder can be used.

After application and hardening, the foam is able to withstand temperatures from -40 to + 80 degrees. The product loses its properties only with constant exposure to direct sunlight. In the absence of such an impact, the technical parameters of the foam do not change for decades.

Thanks to the use of a pistol, the agent is distributed strictly in the direction and in the amount that is needed.

Also, thanks to this, the highest possible speed of work is achieved.

Application nuances

Before starting work, it is necessary to completely clean the surface of dust, oils, various types of grease and other contaminants. It is necessary to remove all unnecessary elements, all porous areas must be grinded off. A coat of primer can be applied to increase adhesion between the surface and the foam. When working, it is important to have a special cleaner or solvent on hand to immediately remove any accidental splash of foam on a clean surface.

You can use polyurethane foam only if the cylinders were in a room with a positive temperature. If the temperature of the cylinders is significantly lower than room temperature, it is necessary to leave them for 12 hours in order to raise their temperature to the desired level.

It is necessary to apply foam strictly according to the instructions. Recommendations for use are usually indicated on the foam canister and sometimes on the gun. The foam expands by about one third. When working, this fact must be taken into account. If too much foam is applied, sagging may occur. It is also necessary to monitor the level of moisture in the cavity that the product will fill. At high humidity, the foam "shrinks" and loses its properties.

The curing rate of Makroflex FR77 fire-resistant polyurethane foam is one of the highest among analogues. Therefore, if you want to get a high-quality result, it is extremely important to monitor the cleanliness, the optimal amount of the applied composition and the conditions for carrying out all stages of work.

See the following video for the test of Makroflex FR77 fire-resistant polyurethane foam.

The comment was sent successfully.