Making a mini-tractor with your own hands

A mini tractor is an extremely useful tool in the agricultural sector. They can do dozens of different jobs: from planting winter crops to harvesting and removing snow. If the farmer has the skills to handle equipment and tools, then independently assembling the unit for him will not be very difficult. In this case, the cost of the main device will be minimal.

Tools and materials

A small tractor greatly helps farmers in their work. They can cultivate the land of personal and summer cottages, and harvest. The big advantage of the unit is that a wide variety of attachments can be connected to it. A compact mini-unit is good for everyone, only it costs a lot of money. Even Chinese manufacturers have started to raise prices significantly in recent years. Therefore, some craftsmen make small units with their own hands, and these mechanisms are not inferior in quality (sometimes even superior) to factory products.

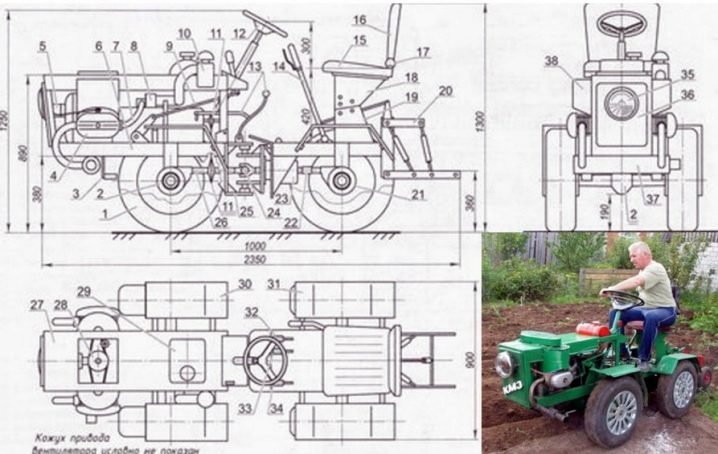

Before starting such work, you should understand how this or that node works, how it works, what features it has. Such equipment on the farm is needed, as a rule, for 3-4 types of work, therefore, when creating the unit, you can "place accents", for example, strengthen the frame (if it will have an increased load) or put wider wheels if the main work will take place in field.

It is quite simple to make a mini-tractor, it will not differ much from a real tractor. First of all, you should make a plan diagram of how to create such an aggregate. There are many used spare parts on the market from motorcycles, VAZs and UAZs, so finding a suitable unit will not be difficult.

The beam / bridge can be made with additional fasteners, since often the factory counterparts do not have the required strength factor. A homemade tractor can be without a cab, but this is not always justified, especially when working in hot or cold seasons. PTO is a power take-off shaft that makes it possible to operate attachments. Shaft types:

- conjugate,

- autonomous;

- working synchronously.

The frame can be made from corners "6" or pipes with a diameter of 45 mm. In order for the structure to be more stable and durable, metal plates (6 mm thick) are welded at the corners. The checkpoint can be taken from the VAZ. It is important that in its working condition there are at least three forward speeds and one rear speed. Traction can be "borrowed" from a motorized carriage. The steering column will fit perfectly from the domestic auto type "Zaporozhets". It is also realistic to make a mini-tractor with different engines - both single-cylinder air-cooled and four-stroke carburetor ones. Such power plants are ideal for creating agricultural machinery.

Benefits from creating a miniature tractor with your own hands:

- low price;

- you can make a unit that will best meet personal needs.

Among the disadvantages are:

- the process of creating a tractor may seem like a laborious affair for those who have worked little with equipment;

- car engines run on gasoline, which is more expensive than diesel fuel;

- it is impossible to drive on federal highways on such equipment, you can get a fine.

How to do it yourself?

The creation of a miniature tractor begins with the installation of a frame, which can be made from tubes. Such a structure should be made powerful, but at the same time it should not be very heavy.Often the frame is made double. Units with the so-called "breaking" frame with all-wheel drive from the GAZ-52 are also popular. The "breaking" frame makes it possible to turn the tractor along a small radius, which increases the maneuverability of the device. The most important blocks of a mini tractor:

- wheels;

- bridges;

- transmission;

- power point.

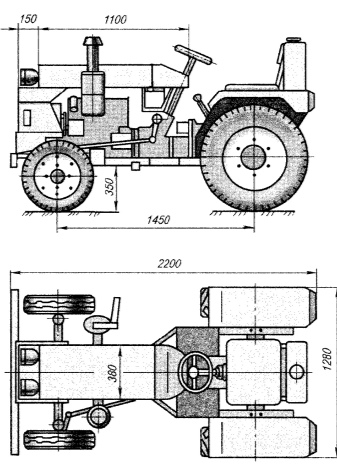

A mini-tractor, made independently at home, begins to be created with the study of drawings and a schematic plan. Taking a "related" project as a starting point, you can edit it, make your own adjustments. After an individual project has been prepared, it is drawn on a piece of Whatman paper. Next, you need to collect all the necessary components, make the basis of the future unit. The dimensions of the frame can vary depending on the purpose of the machine - it can be 1.5-2.5 meters long, 1.3-1.8 meters wide.

A very important unit is the hydraulic drive, it provides many advantages in operation and makes it possible to control a variety of equipment. The hydraulic unit is especially valuable in this regard. Its presence will allow the use of a wide variety of attachments - from KUHN to a snow brush. Hydraulics consists of:

- hydraulic cylinder 76x80;

- distributor P82;

- pump NSh12.

The pump runs at 1000 rpm and sometimes needs to be turned off. With the engine, things are not difficult, the power plant can be supplied from any car or motorcycle.

Quite good engine UD 25. This is a two-cylinder unit with a capacity of 12.2 liters. sec., engine volume - 0.43 liters. The model is very successful, although it is no longer produced, but there are a huge number of such units on the secondary market. Such a model costs no more than 8 thousand rubles. The checkpoint can be taken from a VAZ or ICE "Ant". If the tractor is used in the field, then it is rational to take wheels of 20-24 inches. The front beam is easy to prepare:

- two "cams" are assembled, which can be taken from the "Zhiguli";

- a square is made from a pipe (45x45 mm) by welding;

- to the frame are attached by welding corner-posts "4", to them are mounted and fixed "cams" of turns, put the steering.

The beam of the mini-unit has a swinging mechanism, which is taken from the VAZ, together with the crosspiece. You can also take a similar item from UAZ. It is very important that bridges have congruent gearboxes. This must be done so that the wheel rotation ratio is the same. The checkpoint is taken from any car. With 2 boxes, the mechanism will be even more functional.

It is important to take into account that when installing a hydraulic booster, a certain engine power is spent on its maintenance. If the engine is low-powered, then it is better not to install the valve body. PTO begins to rotate from the engine crankshaft, respectively, it depends on the number of revolutions of the power plant. There is also a PTO of a synchronous type, its rotation ratio is related to the amount of gear ratio of the mechanism. This function is in demand, for example, when carrying out a sowing campaign.

The creation of a point suspension allows the use of additional equipment for the technique. The three-point suspension is also very important, it needs to be dynamic both horizontally and vertically so that you can better control the machine. It is advisable to put the brake on the rear wheels. You can take ready-made units from VAZ, you can also "borrow" brake pads there. The clutch can be removed from any old Zhiguli or GAZ. The steering is also taken from VAZ. It is better to provide a cabin for the unit, then it will be more comfortable to work, labor productivity will increase significantly. This knot can be made from pipes with a diameter of 20-25 mm, which are welded in the form of a frame. It can then be upholstered:

- plywood;

- with tin;

- plastic.

Each unit has its own characteristics, so the drawing should always be paired with a specific device. For example, it is often necessary to mount mechanisms:

- board rotary;

- rear wheel drive;

- small skid-steer mechanism.

Typically, the height of the cabin does not exceed one and a half meters, the ceiling above the worker's head should be at a distance of 20-30 cm. Before making the cabin, the “skeleton” of the product should be assembled from wooden blocks. After everything is clear with the dimensions, you can cut the tubes. The frame fastenings are made using welding. After the frame is ready, it is sheathed, glass frames are installed, etc. The most time-consuming part of the work is creating the doors. You will need to mount the following elements:

- thin tubes;

- sprains;

- fastening.

The structure must be light and strong at the same time. Gas elevators can be installed to make the door close automatically. From the inside, the cabin can be sheathed with leatherette or foam rubber sheets if you have to work in the cold season. You can also make a caterpillar tractor with your own hands. This technique is highly dynamic and agile. Caterpillars have a gentle effect on the ground, so using such a mechanism is beneficial in many ways.

The frame is made of corners, pipes or channels. The engine is preferable to install a diesel one. The front and rear axles can also be "taken" from the VAZ. A good checkpoint is in the GAZ-53. Caterpillars are made of tires, they are cut off with the help of a sidewall grinder. Wheels are mounted on the resulting identical rubber blanks. In order for the car to dynamically perform maneuvers (turns, etc.), it is imperative to install a differential that can disable the rear and front wheels if necessary. This is done like this: the brake pedal is pressed, the differential is switched. One wheel freezes, the second continues to move, the unit turns in this case.

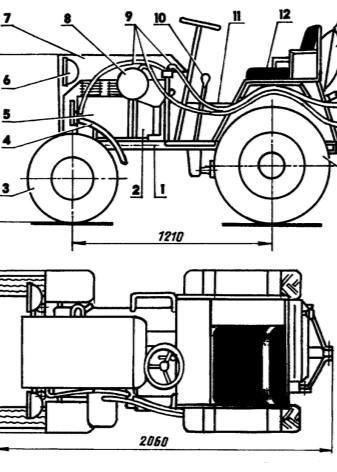

From a cargo scooter

If you make a tractor from a scooter (for example, "Tula 210"), then it will weigh no more than 90 kg. If the main units are taken from one “source” (it can be “GAZ”, “VAZ” or “Oka”), then it will take less time to revise and fit parts. A magneto with one pole is placed on the engine shaft. When installing final drives (1: 4), the mechanism will be able to operate at minimum speeds, while the tractive effort will not change. This factor is very important during harvesting as well as sowing.

The frame is made of 4 corners. The container for fuel can be "borrowed" from a passenger car or made yourself from a sheet of steel 2 mm. On such a mini-mechanism, you can transport up to three hundred kilograms of various loads, plow up to 17 cm deep.

From "Oka"

A mini-tractor can be made by taking spare parts from Oka. A small car can successfully match the parameters of a small agricultural unit. In any case, wheels, engine, fuel tank, transmission - all these components may well fit. Such a unit will differ in power and economical consumption of fuel and lubricants. Such a mechanism will cope with the following types of work:

- hilling;

- soil processing;

- plowing;

- transportation of goods.

From "Oka" the following nodes are used:

- power point;

- transmission;

- bridges;

- Checkpoint;

- wheels;

- steering rods;

- chassis.

The manufacture will require tools and some materials:

- welding machine;

- screwdrivers;

- turbine;

- metal sheets.

To make the frame, you need a pair of spars (made of 10 channels), as well as two traverses (12 and 16). For lateral fastening, you can use the corner "6". It is better to put the engine in a four-cylinder, with a capacity of 45 liters. with., since it has an air cooling system. It is not necessary to remodel the bridge, it can be left unchanged. To make the transmission, you need to attach the gearbox to the base frame. In the flywheel of the engine, the back wall is cut off, a hole is cut in the center.

To maintain the correct pressure in the hydraulic system, a pump is required, which is placed next to the shaft. Each wheel of the shaft is driven by a gearbox.If there will be a lot of work on rough terrain and in the field, it is better to put larger wheels (up to 24 inches). Usually such units are assembled without springs. It is better to reinforce the side members both in front and in the back. It is permissible to take the checkpoint from the Oka. If we install the engine from "UD2" (it is more powerful), then it will be possible to work with large sections and transport heavy loads. The cabin, lighting, fuel tank are installed.

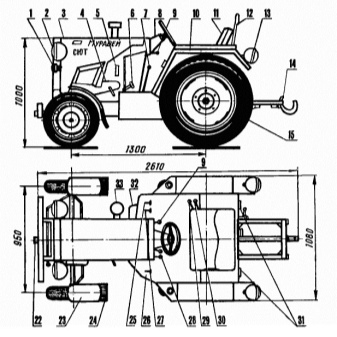

From LuAZ

The unit made from "LuAZ" can be all-wheel drive, and the rear-wheel drive can be turned off if necessary. It takes a small amount of effort and labor time to make such a tractor. The engine can be supplied by Sadko DE-310, two gearboxes can be supplied to it. The frame is made of corners or channels. For the operation of the hydraulics, the H12 pump is used, a 78x110 hydraulic cylinder and a P82 distributor are operating in it. The pump is only used in some cases. The shaft, as well as the gearbox, can be taken from any motorcycle, sometimes the shaft is cut (or prolonged), a new "asterisk" is put on it. The power take-off shaft is also easy to make, it will be no more than 1.5 thousand revolutions per minute.

From "Zhiguli"

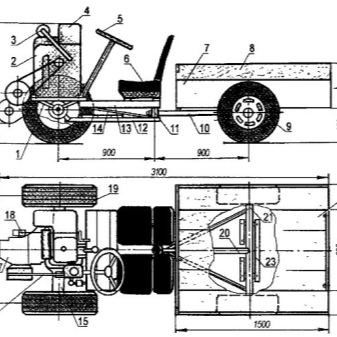

The easiest way is to create a tractor from Zhiguli, this is the most acceptable option. You can always find a variety of spare blocks for it. Unfortunately, the power plant in Zhiguli runs on gasoline, which is not cheap nowadays. The lion's share of agricultural machinery runs on diesel fuel. When planning a project to create a mini-tractor from Zhiguli, several issues should be resolved. The engine is placed in front of the driver and must have a protective screen. The frame is made from corners "4", its size is 1.2 x 2.1 meters. The fuel tank is located at the back, you can make it yourself from tin or take it from any car.

The front suspension is necessarily reinforced. The drive is done on 4 wheels. All work is done according to the following algorithm:

- a schematic drawing is being prepared;

- the frame is made;

- a body is created;

- all nodes are linked;

- steering is installed.

A mini-tractor from Zhiguli 2106 will be powerful enough to do all the necessary work and carry loads of up to 500 kg. Also, when creating it, you can take various nodes. The gearbox is taken from the GAZ-53, the axles are taken from the Zhiguli. Wheels can be taken from MTZ-84. When installing the wheels, the axles should be strengthened, it may also be necessary to change the brake.

The VAZ engine has a power of 59.4 horsepower (there are also more powerful ones). Engine displacement - 0.65 liters. It has good efficiency and relatively low fuel consumption. When creating a mini-tractor from "VAZ", you should especially carefully draw the layout and location of all units. At the very beginning, you should decide on the location:

- Checkpoint;

- fuel containers;

- power plant;

- protective screen;

- cabins.

It is rational to make the frame shorter, and it is better to put a more powerful suspension. The checkpoint can also be taken from GAZ-53, wheelsets from various cars. From "VAZ" only the rear axle and steering block are suitable. If the plans include the installation of all-wheel drive, then you need an engine of at least 42 liters. with. Such a unit will be able to pull the hydraulic PTO shaft and will work normally with increased load. It is better to make a tractor with four-wheel drive.

The process of creating a mini-tractor from "VAZ":

- carrying out welding work with the frame;

- installation of the chassis;

- installation of wheels and fuel tanks;

- installation of the power plant and transmissions;

- installation of the cabin, protective screen (casing).

An important part of the work is shortening the rear axle:

- the cup is cut off, the flange ring is removed;

- the semiaxis is removed, machined;

- a hole is drilled inside the cup;

- the axle shafts are aligned and welded;

- the bridge is inserted into the finished recess;

- welding works are in progress;

- the bridge is attached to the frame using a V-structure.

From "Zaporozhets"

To make a tractor from "Zaporozhets", you should work with the nodes.The front and rear axles can be shortened slightly. The gearbox on the Zaporozhets is not very powerful, it can be replaced with a gearbox from VAZ. The hydraulics are fine, but the hoses and fittings may need to be replaced with newer ones. The cab frame is made of pipes with a diameter of 2 cm, sheathed with plywood or PVC sheets. The engine "Zaporozhets" is quite suitable for a tractor, but you can put something more powerful. If you install the "VAZ" checkpoint, then it will be possible to work with any attachments. All used units must be thoroughly cleaned and checked.

From a motorcycle

You can also assemble a tractor from the Ural motorcycle.

It was done like this:

- The frame is welded, which consisted of two blocks. The pipe is 2.1 meters long and 0.95 meters wide.

- The transmission comes from VAZ. The torque impulse is transmitted through the chain to the "sprocket", then goes to the propeller shaft in the front and rear axles.

- An electronic ignition is mounted, taken from the "VAZ2109".

- Two gearboxes are installed - from a motorcycle and a Moskvich 412 car.

- The drive is made full. The cylinders are air cooled.

- The steering rods are taken from the "Moskvich".

The machine turns out to be quite powerful, passable, "pulls" without any special difficulties a trailer with a load weighing up to 0.5 tons. It can be used both in agricultural work and for clearing the area from snow.

Safety engineering

When working on a tractor, observe safety precautions:

- to work on a tractor, you need to have special training;

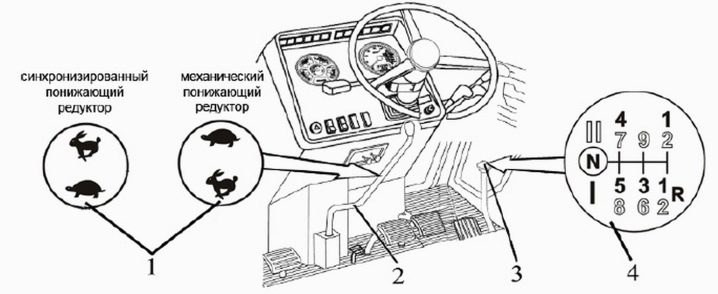

- before starting the engine, the gear shift is in the "H" position;

- the hydraulic distribution clutch is placed in the "Neutral" position;

- a water barrier can be crossed if it is not more than one meter deep;

- it is prohibited to transport people and animals on a trailer;

- only two people can be present in the cab while driving;

- there must be a rubber mat on the floor of the unit;

- before starting work, you should make a preventive inspection of the engine, cab, mountings, gearbox;

- if the car has been standing idle for a long time, you should "drive" it at idle, without loads;

- the rudder travel should be no more than 0.44 rad (26 °), with an indicator of 0.62 rad (36 °), it will be necessary to adjust the hinges;

- the brakes should be checked regularly and adjusted if necessary;

- the pneumatic system must have a pressure of about 0.5 MPa (4.78 kgf / cm2);

- the batteries must be firmly attached to the base;

- the speed of movement is permissible about 25 km per hour;

- attachments must comply with the performance characteristics of the mini-tractor;

- at the beginning of work it is recommended to check all connecting fixtures.

For information on how to make a mini-tractor with your own hands, see the next video.

The comment was sent successfully.