How to make a motor cultivator with your own hands?

A motor-cultivator is an analogue of a mini-tractor, its kind. A motor-cultivator (popularly, this device is also called a "walk-behind tractor") is designed for soil cultivation. This agricultural machinery is produced both in Russia and abroad, and therefore is widely represented on the market. However, it is worth noting the fact that the purchase of a motor-cultivator can cost a fairly large amount. In this regard, many craftsmen with little knowledge of technology, as well as possessing some improvised materials, make a motor cultivator on their own at home.

Peculiarities

Before starting the production of a motor-cultivator, you should decide what type of agricultural unit you will design: with an electric motor or with an internal combustion motor. It is important to remember that a motor cultivator with an electric motor will only be effective if there is an energy supply system in the area to be cultivated. In contrast, a device incorporating an internal combustion engine can be used in the field, since it runs on fuel, namely gasoline.

Important: the maintenance of gasoline motor cultivators will require more financial resources, and it is also quite difficult to maintain them technically.

Another important nuance is the method of soil cultivation. There are cultivators that have wheels with a drive, as well as those units that are equipped with attachments (the latter can serve not only as walk-behind tractors, but also as a means of transportation).

What elements are required for assembly?

If you decide to design a walk-behind tractor yourself, then you need to prepare the following set of building blocks:

- an internal combustion motor or engine;

- gearbox - it is able to reduce the speed and increase the efforts on the working shaft;

- the frame on which the equipment is mounted;

- handles for control.

It is these details that are the main ones - without them, it is impossible to make a machine for agricultural land cultivation at home. Therefore, before starting the manufacturing process, make sure that each of the items described above is present.

Manufacturing scheme

Many experts argue that a gasoline-type walk-behind tractor should be designed independently and at home.

From the chainsaw "Friendship"

Most often, home-made motor-cultivators designed for processing a small private area are made using a Druzhba chainsaw. The thing is that the manufacturing procedure itself is quite simple, and the Druzhba saw can be found in the household of many homeowners.

First of all, you should take care of the manufacture of the frame for the unit. Remember that the frame must be cubic. The engine from the chainsaw is placed and firmly attached to the upper corners of the designed frame, and the fuel tank is installed slightly lower, and the fasteners for it must be prepared in advance.

It is also imperative to use the vertical frame racks: they will accommodate the intermediate shaft supports.

Important: remember that the center of gravity of this design is above the wheels.

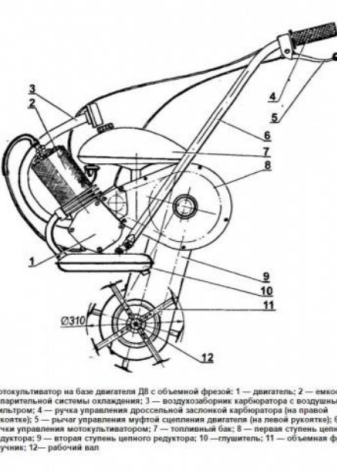

With a motor from a moped

A motoblock from a moped is a motoblock with a D-8 engine or with an Sh-50 engine. That is why for the full functioning of the structure, it is necessary to install an analog of the cooling system. Usually, for this, a tin vessel is soldered around the cylinder, which is intended for pouring water into it.

Important: the water in the vessel must be changed regularly, make sure that the temperature of the cylinder does not exceed 100 degrees Celsius. That is, if you notice that the water has begun to boil away, then you need to suspend work, cool the engine and replace the fluid.

Also, the device must be equipped with a gearbox using a bicycle sprocket. The bottom of such a design will be a thrust, so the output shaft must be secured and reinforced with metal bushings, which must be tightly attached to the gearbox.

In addition, the walk-behind tractor can be made from a snowplow, from a trimmer.

Useful Tips

In order for your motor-cultivator to work efficiently enough and serve you for a long time, it is necessary to take into account some expert advice.

- If you could not find 1 powerful one, then you can use 2 low-power motors (no less than 1.5 kW each). They need to be fixed to the frame, and then a single system must be created from two separate elements. Also, do not forget to put a double-strand pulley on one of the engines, which will transmit torque to the pulley of the working shaft of the cultivator gearbox.

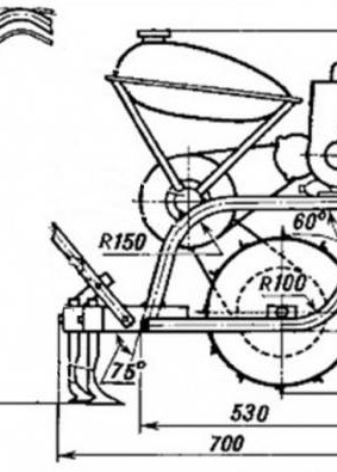

- In order to correctly and efficiently assemble a cultivator with your own hands, you must be guided by the drawings.

- Due to the fact that the rear wheels are support wheels, they should be attached to the frame by means of an axle with bearings.

How to fix the damage yourself?

In the event that you make a mini-tractor with your own hands, you cannot avoid minor breakdowns and malfunctions. In this regard, their solution should be foreseen and considered.

- So, in the event that you cannot start the engine, then most likely there is no spark. In this regard, it is necessary to replace the plug of the device. If that doesn't work, then try cleaning the filters (usually they are washed in gasoline).

- If during the operation of the walk-behind tractor you notice that its motor stalls quite often, then keep in mind that this may be due to broken spark plugs or poor fuel supply.

- If during operation the unit emits a strange extraneous sound, then the reason most likely lies in the breakdown of one or more parts. In this case, you must immediately stop working, disassemble the motor and identify the breakdown. If this is ignored, the engine can jam.

- If the engine makes a lot of noise and overheats quickly, then the reason for this deficiency may be that you are using poor quality fuel or you are overloading the device. Thus, it is necessary to suspend work for a while, give the unit “rest”, and change the fuel.

For information on how to make a motor cultivator with your own hands, see the video below.

The comment was sent successfully.