How to make hydraulics on a mini-tractor with your own hands?

Hydraulics is a technical system that works by influencing the pressure of a liquid on other elements of the system. In the process of exposure, kinetic energy is generated, which is converted into mechanical energy, as a result of which the useful work of one or another mechanism is performed. Various agricultural implements, such as mini-tractors, are equipped with a hydraulic system. With its help, various attachments are controlled.

This system is present in the design of any tractor produced by the manufacturer. It can be modified and optimized to fit your needs. A homemade mini-tractor must be equipped with hydraulics, which will allow you to use the equipment with maximum efficiency.

Design features

The hydraulics on a mini-tractor works on the same principle as all other similar systems. It has a hydraulic pump that builds up pressure in the system and makes fluid move through it. It connects to the filler source, which is the expansion tank. This unit is driven by the transmission of torque from the diesel engine through a belt or mechanical connection with a shaft or transmission.

Although the system is called hydraulic, it is filled with oil. It has a lower boiling point, a suitable expansion coefficient and serves as a lubricant for moving parts of the mechanism.

Flexible hoses with reinforced walls are used to transfer fluid through the system. All their connections are sealed and reinforced. Through them, under the influence of pressure, oil enters the hydraulic valve with a floating position, and then into the hydraulic cylinders that act as pistons. Pistons do mechanical work that drives the associated attachment.

Some modifications of hydraulic mechanisms involve integration into the hydraulic wheel drive system. This installation complements the tractor's braking system, making it easier to use the brakes, especially in homemade agricultural machinery. The hydraulic linkage can also be used to facilitate steering, in this case acting as a hydraulic booster. These design features of the hydraulic system of the mini-tractor allow you to control the operation of all mounted mechanisms, own units of vehicles and effectively perform the assigned tasks.

In order to assemble the hydraulics on a mini-tractor with your own hands, you will need the component parts of the mechanism, manufactured at the factory using special equipment:

- hydraulic pump;

- hydraulic valve;

- fastening hoses;

- hydraulic cylinder;

- other components that cannot be made at home.

The listed elements can be purchased in the store as a complete assembly or dismantled from old specialized equipment, and the rest of the fastening structure can be designed and assembled by hand.

Necessary tools

In each case, you may need your own set of tools and materials required for assembly. Their main set:

- welding machine;

- Bulgarian;

- drill;

- drill;

- taps for threading;

- set of wrenches.

The list can be supplemented with items depending on the assembly conditions.

Required details:

- hydraulic pump;

- hydraulic valve;

- hydraulic tank;

- transmission belt;

- hoses and their fasteners;

- hydraulic cylinders;

- bolts and nuts;

- clamps;

- oil filter;

- various fasteners, the name of which is due to each specific case.

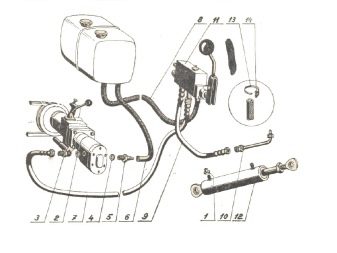

The main components are shown in the photo.

How to do it?

The work on creating your own hydraulic system for a mini-tractor begins with the design of the future structure and calculations aimed at optimizing the ratio of expended resources and efficiency. The tractor power must correspond to its intended purpose, and the technical characteristics of the hydraulic system components are proportional to the loads applied to them.

Insufficient power of the oil pump or low coefficient of permissible load on the hydraulic cylinders can lead to rapid failure of the entire system or individual components. An overestimated level of these indicators will increase the consumption of fuel and other resources, and create an imbalance in the system. To compensate for the difference in technical characteristics and equalize the balance, additional names are installed: the second pump, hydraulic cylinder and others.

In the drawing, it is necessary to reflect the design of the supporting frame, which will include a place for a pump, a distributor, pistons and other additional elements, as well as a hydraulic circuit connection diagram. At the same time, its configuration should be optimized so that the distance from the engine output shaft to the nearest point of transmission of the power of the hydraulic system is minimal.

The pump is installed as close to the drive shaft as possible. The reservoir with the working oil is located above it, which provides a free flow of fluid to the pump blades and reduces the leakage coefficient of useful mechanical energy. A filter is installed between the fluid reservoir and the pump. Its presence extends the smooth operation of the entire system.

By means of reinforced hoses, the pump is connected to a hydraulic valve, which is equipped with control elements. There may be several of them, depending on the functionality of the hydraulics. Since in order to maintain pressure in the system, the oil must continuously circulate through it, the distributor regulates the direction of its movement and supply to the cylinders, and also cuts off the flow at the moment of idle operation. The distributor controls are special levers supplied by the manufacturer with it.

After mounting the distributor, the hydraulic cylinders are installed on the working part of the frame. These elements can be represented by special piston units designed for use in the hydraulic system. In other cases, they can be made independently from oil-type automotive shock absorbers.

Attachments are installed on the tractor in conjunction with hydraulic cylinders - moving parts of the system that transmit mechanical force to it. The design of the fastening mechanisms is determined by the type of equipment, its actual configuration and the nature of the targeted work performed with its help.

The assembled hydraulic system must be equipped with technical assemblies and isolation means that require their mandatory installation. Among them are:

- drain unit in the hydraulic tank;

- pressure relief valve in the tank;

- pressure sensor;

- shut-off valve;

- drain from the pump and hydraulic valve;

- fine filtering elements at the inlet to the hydraulic cylinders;

- sealing rings, washers, gaskets, nuts, clamps.

Before starting work, the entire system is configured.

The working diagram of the hydraulic equipment for a mini-tractor is shown in the diagram:

System operation

Operating instructions for mini tractor hydraulics

The system is controlled by the lever (s), which are in conjunction with the hydraulic valve. Its main (their) function is to change the positions of the distributor control valves, supply pressure to the desired section, disconnect the fluid circulation circuit from the end units of the unit.

A simple hydraulic system has three control lever positions:

- neutral - the oil circulates separately from the pistons;

- piston extension - pressure makes him take the maximally elongated position;

- piston movement - the pressure is released, the vacuum created by the outgoing liquid pulls it along, returning it to its original position.

At the moment of movement of the piston (s), the attachment performs the work provided for by the purpose of its production.

Any hydraulic system is equipped with mechanisms for starting and stopping the hydraulic pump, fixing positions and emergency (manual) control.

Prophylaxis

To ensure efficient operation of the hydraulic system of the tractor, it is necessary to follow the rules of operation and timely maintenance.

When working with equipment equipped with hydraulics, you should regularly check its components for faults. Small scale breakdowns will inevitably lead to failure of the rest of the system. If you find one, you must immediately apply all available means to eliminate it:

- do not exceed the prescribed load on the hydraulic pump, hydraulic cylinders, oil hoses and other components;

- avoid excessively high pressure indicators, if necessary, relieve it in a timely manner or select a suitable control valve;

- to maintain the stable operation of the hydraulic mechanism, it is important to change / add fluid to the system in a timely manner: an insufficient amount will lead to a decrease in operating efficiency and a rapid failure of the unit;

- all maintenance and repair work of the system should be performed with the tractor engine off (to “cold”) after the pressure has been released.

Table of common faults in hydraulic systems and how to fix them:

Malfunctions and their causes | Remedy |

Fault: low lifting and pushing force of hydraulic cylinders or its complete absence. Reason: the oil level in the system has dropped. | Add oil. |

Oil with unsuitable characteristics has been used. | Change the oil to a suitable one. |

Oil filter or hydraulic cylinder dirty. | Replace or wash the filter element. |

Air in the system. | Purge the system - remove air, identify the point of its entry and eliminate it. |

Fluid leaking from worn oil seals. | Replace oil seals with new ones. |

The operation of the relief valve, pressure is broken - jamming occurs in the open position. | Flush / purge the valve. Replace if necessary. |

Malfunction in the valves of the directional control valve. | Replace valves or their parts, if necessary replace the entire block. |

Leaks at the docking points of the system. | Check for leaks, found to be eliminated by crimping, tightening, installing clamps, replacing. |

Defective piston or hydraulic cylinder seals. | Check hydraulic cylinder for pressure leaks. Replace oil seals, piston. If necessary, change the unit as a whole. |

How to install hydraulics on a mini-tractor with your own hands, see the next video.

The comment was sent successfully.