Subtleties of choosing diesel engines for a mini-tractor

Mini tractors are a completely modern and adequate type of garden, vegetable garden and field equipment. But ready-made designs do not always satisfy the needs of consumers. In addition to the need to complete self-assembled tractors, you need to be able to select diesel engines in the event of a breakdown of the factory power plant.

Peculiarities

The key characteristics of propulsion systems are their total power and operational stability. Diesel engines for mini-tractors made at Russian and Chinese factories are now quite widespread. Domestic products are ideally adapted for operation in the most severe climatic conditions. The Chinese one is almost not inferior in this indicator, in addition, promising technological solutions are used in it. The equipment of both countries is quite reliable and inexpensive (if we are talking specifically about the products of trusted companies, of course).

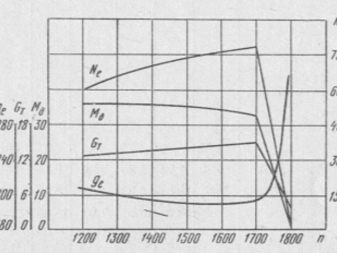

Along with the generated power, indicators such as are very important:

- total fuel consumption (per unit of time or in terms of 1 ha);

- generated torque;

- number of working cylinders;

- combustion chamber capacity;

- the intensity of the release of toxic substances.

All mini tractor engines are designed from the ground up for impressive operating loads. Also, the mode of rotation of the shaft with the lowest speed is taken into account everywhere. Almost every model of motors produced is equipped with auxiliary output shafts, which differ in a strictly specified frequency of rotation. With the help of such a shaft, the force from the engine is transmitted to:

- mowing machines;

- harrows;

- potato diggers;

- seeding machines;

- other mechanisms.

Practical advice on the selection of power plants

The more power of the diesel engine, the higher the permissible weight of the connected devices. When the mechanism can create a force of 21 liters. with. and more, it will be possible to connect even cargo trailers. The more cylinders a motor has, the more powerful it is. However, it must be remembered that two-cylinder power units, not to mention more serious modifications, are significantly more expensive in everyday use. Even for processing a plot with an area of 40 to 50 acres, a machine that generates an effort of up to 18-20 liters is quite enough. with.

Important: it is better if the warranty period for the motor is not a standard year, but more. If the quality and stability of the mini-tractor is in the first place for the consumer, it is required to give preference to the German and Japanese versions. Companies from industrialized countries usually use the most advanced alloys. In addition, special strength tests are carried out there, the characteristics of the finished product are carefully monitored. But if the requirements are not so great, you can safely give preference to simpler models.

When making a decisive choice, it is necessary to take into account the ratio of stability of operation, total performance, functionality and motor power. Be sure to pay attention to the proportion between power and the amount of fuel consumed.

The better this proportion, the higher the profitability of using the engine. But there are no clear, rigid recommendations here. Only personal experience will tell the farmer which parameters are most important and which can be left in the shade.

What should be done to change the motor less often?

The work of a mini-tractor only seems like a daily routine for its owner.For the motor, it brings a significant load. Therefore, strictly those oils recommended by the manufacturer should be poured into any motor. It is not recommended to subject the tractor and its drive to prolonged overload, to start the device without preliminary warming up in winter.

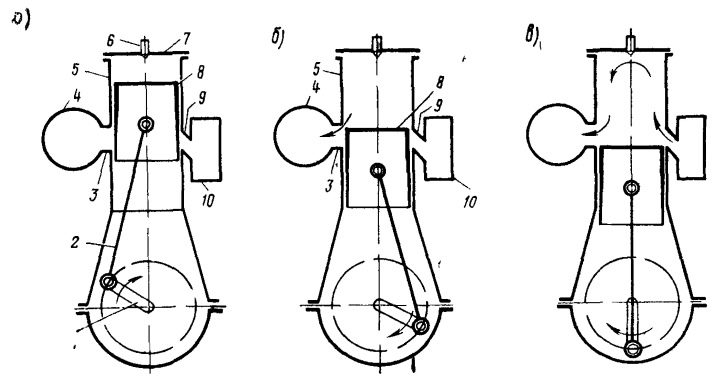

Occasionally there are complaints that the mini-tractor has started in the opposite direction; Usually, the stream of smoke still comes out not from the muffler, but through the filter. This type of malfunction is typical for diesel engines, especially for two-stroke operation.

This is due to unauthorized launch in the wrong direction. The erroneous heading is associated with malfunctions in the ratchet or starter. In normal operation, they should direct the motor forward.

Important: on new engines, this problem is often associated with improper break-in or its complete absence.

It should be borne in mind that buying used motors is not a good idea. New power plants have a proprietary warranty. But if you buy a product "off-hand", you can face serious problems. Claims about the shortcomings of such units can not be made to anyone. If, nevertheless, a used spare part is purchased, you need to pay attention to:

- surface condition;

- the slightest extraneous sounds;

- ease of launch;

- optimal (not white and not blackish) exhaust flow.

For an overview and characteristics of a diesel engine for a mini-tractor, see below.

The comment was sent successfully.