Making a mini-tractor 4x4 with your own hands

Agricultural work in the garden, in the garden can bring joy to people. But before you can enjoy the result, you will have to work hard. Homemade miniature tractors help simplify your life and increase your productivity.

Design features and dimensions

Of course, this technique can also be bought in the store. But the costs in this case are often prohibitively high. And what is most annoying, for the largest land, where powerful machines are required, the purchase costs rise sharply. In addition, for those interested in technology, the preparation of a 4x4 mini-tractor in itself will be pleasant.

But it must be borne in mind that when working independently, you will have to carefully think over all the nuances. There is no point in making the design worse than on the factory models.

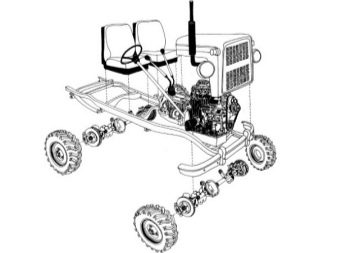

First, they determine what kind of work is to be performed on the site. Then the appropriate attachments are selected, the optimal placement and methods of attaching it are determined. It is customary to divide home-made mini-tractors into the same parts as their "shop" counterparts:

- frame (the most significant detail);

- movers;

- power point;

- Gearbox and gear unit;

- steering block;

- auxiliary (but not less important) parts - clutch, driver's seat, roof and so on.

As you can see, most of the parts from which homemade mini-tractors are assembled are taken ready-made from other equipment. Can be used as a basis for both cars and other agricultural machines. But the number of possible combinations of components is not that great. Therefore, it makes sense to focus on ready-made combinations of parts. As for the dimensions, they are chosen at their discretion, but as soon as these parameters are fixed in the drawing, it becomes extremely imprudent to change them.

Most experts believe that it is best to use a structure with a break frame. And experienced craftsmen prefer this option. Walk-behind tractors are taken as a basis.

Despite their apparent bulkiness, these mini tractors are quite efficient and perform very well. The main thing is that each component is put in its strictly designated place.

Tools and materials

Frames are often made from traverses and spars. The spars themselves are made up of channels and steel pipes. Crossbars are made in a similar way. In this regard, the preparation of any mini-tractor is not much different. For motors, any version that is powerful enough will do.

But still professionals believe that The best option is a four-stroke water-cooled diesel engine. They both save fuel and are more stable in operation. Gearboxes and transfer cases, as well as clutches, are often taken from domestic trucks. But it must be borne in mind that the individual components will have to be adjusted to each other. For this purpose, you will have to use a home lathe or contact a professional.

Bridges are taken from old motor technology almost unchanged. Sometimes only they are shortened a little. In this case, metalworking equipment is used. Wheels are sometimes removed from cars, however, their diameter must be at least 14 inches (for the front axle).

By installing smaller propellers, farmers will often find the mini tractor sink into the ground.If the undercarriage is too large, maneuverability will deteriorate. Hydraulic power steering helps to partially compensate for this disadvantage. Whether to remove it from old cars, or do it yourself - it's up to the master to decide. As for the driver's seat, although optional, it is a very important element.

If an old walk-behind tractor is taken as a basis, then you can take it ready-made:

- motor;

- Checkpoint;

- clutch system;

- wheels and axle shafts.

But the frame from the walk-behind tractor can only become an integral part of the mini-tractor frame. Using it, you need to make sure that the mounts for the motor and gearbox are ready. If a motor-cultivator is taken as the basis, they refuse from a powerful frame, and a 10 cm square pipe is enough.Preference is given to a square shape because home mini-tractors often drive on bad roads. The size of the frame is selected according to the size of the other parts and their weight.

A simple type of transmission involves the use of a belt clutch fitted to the gearbox. In a more complex version, the torque is transmitted using cardan shafts. However, the consumer has no choice - it all depends on the characteristics of the engine and on the wheel formula. If an efficient breaking frame is used, then in any case, you will have to install propeller shafts. It must be borne in mind that it is difficult to make it yourself.

Management is created according to a standard scheme, they just take parts from any car. Since the load on the steering wheel when operating a mini-tractor is less than that of a passenger car, you can safely put used parts. Securing the column, tips and other components is exactly the same as on a car. But the tie rods are shortened a little to match the narrowed track. To work, therefore, you will need:

- Angle grinder;

- screwdrivers;

- spanners;

- roulette;

- welders;

- hardware.

How to do it yourself?

The homemade mini-tractor of a break is a kind of classic in a similar technique. Therefore, it is worth starting the review with him. There are 3 different options for how to implement such a scheme:

- use a walk-behind tractor and put the factory frame on it;

- assemble the product completely from spare parts;

- take the walk-behind tractor as a basis and supplement it with spare parts from the alteration kit.

It is extremely important to prepare drawings before starting work. In the absence of work experience and technical drawing, it is better to turn to professionals. Ready-made schemes distributed over the Internet cannot always guarantee an optimal result. And their publishers, especially the site owners, are not responsible. A hinge link must be provided between the frame parts.

The engine is placed in the front in most cases. For the manufacture of the frame, channels from 9 to 16 are usually used. Only occasionally channel number 5 is used, however, it will have to be strengthened with cross beams.

Cardan shafts are often used as a hinge link on a mini-tractor with a breaking frame. They are removed from the GAZ-52 or from the GAZ-53.

Experts recommend installing four-stroke motors on homemade equipment. Power 40 liters. with. quite enough to solve most of the economic problems. Engines are often taken from Moskvich and Zhiguli cars. But you need to pay attention to the gear ratios. You also need to take care of efficient cooling. Engines that are not cooled well will lose power and their parts will wear out quickly. To make the transmission, it is advisable to use the ones removed from the trucks:

- power take-off shaft;

- gearbox;

- clutch system.

But in finished form, all these parts will not work for a mini-tractor. They will need to be improved. The clutch and motor will only be properly connected with a new basket. The rear flywheel segment will have to be shortened on the machine. A new hole must be punched in the middle of this knot, otherwise the fracture knot will not work properly.Front axles are taken from other cars in finished form. Intruding into their device is not recommended. However, the rear axles should be slightly improved. The modernization consists in shortening the axle shafts. The rear axles are attached to the frame using 4 ladders.

The size of the wheels on a mini tractor used only for moving loads should be 13-16 inches. But when it is planned to carry out a wide range of agricultural work, it is necessary to use propellers with a radius of 18-24 inches. When it is possible to create only an excessively large wheelbase, hydraulic power steering should be used. A hydraulic cylinder is a device that cannot be made with your own hands. The only way to get this part is to remove it from unnecessary equipment.

To maintain the operating pressure at the desired level and circulate a sufficient amount of oil, you will have to install a gear-type pump.

It is important when making a fracture to connect the gearbox with the wheels mounted on the main shaft. Then it will be much easier to manage them.

The operator's seat is taken from passenger cars and does not need to be altered. The steering wheel is placed so as not to rest against it with your knees.

When assembling control systems, it is necessary to ensure that all of them have free access. A high-quality break, even if it is assembled from old spare parts, should produce up to 3000 engine revolutions in a minute. The lowest speed limit is 3 km / h. If these parameters are not provided, it will be necessary to alter the mini-tractor after the test run. Adjust the transmission if necessary.

Experts note that all drive wheels, if possible, should have separate gearboxes and hydraulic distributors of 4 sections. This solution makes it possible to abandon the installation of cardan shafts and the use of differentials on the rear axles during assembly. The mini-tractor can only be loaded after successful running-in. In many cases, miniature tractors are made from Niva components. In this case, sequentially:

- assemble the frame;

- put the engine;

- mount the transmission;

- hang the steering column;

- fixing hydraulic components and wheels;

- equip the brake system;

- put the seat and cargo box.

The classic approach to the arrangement of the frame based on the "VAZ 2121" implies an all-welded structure. It is relatively easy to make it. However, the maneuverability of such a system is not great, which is especially felt when the mini-tractor turns or drives over rough terrain with a load in the back. Therefore, the increased complexity of the fracture assembly is fully justified by the high cross-country ability and the reduction in the turning radius.

The crossmembers act as stiffeners. Longitudinal spars are placed in such a way that a rigid steel box is formed. It is necessary to provide brackets, fasteners, without which the body will move unpredictably. A pair of semi-frames are welded together. A piece of 0.6x0.36 m is placed at the back, and 0.9x0.36 m in front.A channel of the eighth size is taken as a basis. A couple of pipe sections are added to the frontal semi-frame. These sections will allow the motor to be installed. A metal rack 0.012 m thick is placed on the rear semi-frame. An equilateral corner is used to strengthen it.

Behind the rack, a rectangular block is welded on, which becomes a rear hitch for auxiliary tools. And on the front semi-frame, a support platform for the seat is mounted on top. Steel forks must be welded to the central parts of both half-frames. A hub is installed in front, removed from the front wheel of the car. Then it will move in two planes.

You can also use parts from "Zhiguli". The motor is taken from a variety of models in this series. The front suspension must be reinforced, and the power plant is placed under the operator's seat. The engine must be covered with a shroud. When the drawings are being prepared, the exact location of the fuel tank must be indicated. To save money, you need to use a shorter frame, but when shortening it, you must not forget about the shift of the bridge.

Home-made mini-tractors with the Oka engine also perform well. If you assemble such a device according to the scheme, you get a compact product. An exact diagram is also needed then to determine the need for channels, corners and fasteners. The seat is made from any suitable item. The front axle is made of steel bars with a minimum thickness of 0.05 m.

Safety engineering

Regardless of the nuances of the design and the selected models, work with a mini-tractor must be done with caution. Every time before starting it, it is necessary to inspect all parts of the machine, check their suitability. First of all, the serviceability of the braking system should be assessed. Stopping is made only at low speed, and the engine can be turned off only when the clutch is depressed and the brake is gradually released. An emergency stop is made only in an emergency.

Both the driver and passengers can only ride in adapted seats. Do not lean on the tie rods. Driving on slopes is only allowed at minimum speed. If the engine, lubrication system or brakes are “leaking”, do not use the mini-tractor. You can mount any attachments only on standard mounts.

For an overview of a DIY mini-tractor, see the next video.

The comment was sent successfully.