How to make a microphone with your own hands?

A high-quality, good, hand-made microphone surpasses industrial ones. It makes sense to save on a good microphone by making your own - no worse than a purchased one.

Features of homemade microphones

The price of a homemade product is less than 100 rubles. Both the housing and the printed circuit board are not manufactured in full compliance with general technological requirements. Electret microphones are the simplest and cheapest, easily removable from outdated recording equipment. Their source is any cheap headset for a smartphone or computer. It's easy to make a stereo microphone - for example, if you're broadcasting from an FM modulator on the top floor of your high-rise building.

Radio components for the simplest microphone amplifier cost almost a penny. PCB material is optional.

Tools and materials

For normal assembly based on a printed circuit board, to give the device solidity, build quality, you will need the following materials.

- (Glass) textolite or getinax - one-sided foil. Copper plating.

- Solder, rosin and soldering flux. You cannot do without work with a soldering iron: installation on screws and nuts is time consuming and complicated, and on twists is unreliable, since the oxidation of copper wires will change the operating parameters of the circuit for the worse.

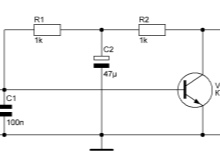

- Radio parts: resistors, capacitors, low-frequency and low-power transistors, microphone. In total, they cost a penny - to amplify the microphone, you only need one low-power amplifier stage based on a transistor operating at low frequencies. Stereo microphones require two identical stages (one stage per head).

- Electrical wires. Among radio amateurs, a KSPR or KSVR cable with one or two pairs of wires is popular - as tracks if the PCB material does not have a conductive foil. As wires supplying current and a high-frequency signal, a ShVVP-type cable with a cross section from 0.75 to several square millimeters for each of the wires is used. Individual "conductors" can be removed from a stranded copper cable and used as prefabricated (current-carrying) conductors on a non-foil board.

- Coaxial cable of any size - without it, the microphone will send a background sound to the terminal amplifier (or radio transmitter), which spoils the quality of sound recording / sound transmission.

- Frame - flat-cylindrical, conical with a rounding at the wide end. Plastic, composite, and aluminum alloy are used as the body material.

- Connector and plug standard Audio 3.5 mm (Jack). PCs, laptops and gadgets may also require a 2.5 mm jack diameter (some mobile phone models that are not smartphones).

Electrodynamic and carbon microphone heads are more difficult to find: it would require disassembling a public city telephone set, which today has been supplanted by mobile phones and is found only in public and private offices.

Electret microphones are used in the compact headset. The studio microphone is a vanishing rarity. If you do not work as a DJ at a radio station or as a producer in a film studio, you are unlikely to fall into a studio microphone, in which the electronics failed. Expensive microphones with a gold membrane are being repaired - the head itself costs more than a thousand dollars.

Of the tools you need such.

- Cutter - useful for cutting non-conductive grooves in the foil layer. The classic method is reagents for preparing a solution of ferric chloride used for etching printed circuit boards.

- Soldering iron... Supplied with a stand - for ease of use.

- Mini drill... It can be made on the basis of a motor from a toy car, to the shaft of which a thin drill with a diameter of up to 1 mm is attached to the shaft using a tube from a ballpoint pen rod that has served its life. This homemade drill runs on 5 volts from a smartphone charger.

- Glue gun, into which the hot melt glue tube is filled.

Having prepared the necessary tools, radio materials and radio components, they begin to assemble a homemade microphone.

Manufacturing steps

Sensitive for recording music and speech at a distance of up to several meters, the microphone includes one or two microphone heads, one or two stages of a pre-amplifier. You cannot connect the microphone directly to the main amplifier - especially to an active speaker if you are doing vocals, you cannot. The signal strength is so low that the resulting sound will not "swing" the more powerful transistors or stages in the microcircuit. The microphone sound must be pre-amplified - for example, from 100 μW to 100 mW. Then the active speaker will raise it in power up to 10-100 watts.

Achieving a sound power gain in an amplifier is a million times an order of magnitude more difficult. Such a system will not work well.

The manufacturing steps are as follows.

- Prepare a ready-made case for installation or make a new one from scratch. A piece of metal-plastic water pipe is suitable as a microphone handle. To accommodate the microphone unit, for example, a case from a small-sized wireless speaker is used. A craftsman will make it even from a ball or cylinder from any baby rattle. Kinder Surprise Chocolate Eggs, for example, contain a flat-cylindrical capsule with rounded ends. A small case is also suitable, in which a robot machine sells sealed shoe covers to visitors to hospitals and clinics.

- Cut a small rectangular piece from a sheet of fiberglass or getinax. Draw on it with a varnish or a track marker, guided by the circuit topology. Etch or grind off excess foil that has not been painted over with varnish or marker. Drill holes in the board where radio components and wires are inserted.

- Place the radio parts, referring to the assembly drawing of the diagram. Cover the tracks with a thin layer of solder to prevent oxidation. Solder parts and wires.

- Connect and test the assembled amplifier board and the microphone itself. To improve the sound quality from a low-impedance speaker acting as a microphone head, a variable resistor, a capacitor (RC filter) and an output transformer from a tube radio are used. The variable diagram (frequency response, or amplitude-frequency characteristic) is adjusted using a variable resistor. In the simplest case, checking the board is performed using ordinary headphones. An additional amplifier is needed for the loudspeaker. The microphone needs external power - it is supplied through the same cord where the amplified sound is removed (so-called phantom power).

- If the device works, insert the board and the microphone head into the case, remove the wires. Assemble the case and solder the plug to the microphone output cable.

Connect the microphone to your PC, laptop or powered speaker. The sound should pass clearly, and its quality at home will be high.

Hidden microphones are made as compact as possible - they even fit into the case from the handle. At the same time, they are no less highly sensitive than the microphones that come with the "gaming" headset in the form of full-size headphones. Decorated in the form of LED backlighting, hiding their true purpose - provided they are powered by a separate battery or batteries.

Ribbon microphones are assembled as flat devices... A strip of foil is glued to a sheet of paper. A magnet is placed under the paper. The wires from the ends of the strip are connected in series through a transformer and an RC circuit. Laser microphones are made from a laser pointer, and an object (a geographic map or a picture on the wall) is used as a membrane, vibrating from any sounds. The difference in the delay of the reflected laser beam is detected by a light sensor. These vibrations are used to recreate electrical vibrations.

For information on how to make a microphone with your own hands, see the next video.

The comment was sent successfully.