Phillips screws

Various installation work requires a large number of different fasteners. All kinds of screws are widely used. Special cross-recessed fasteners are currently available. Today we will talk about what features they have, and about the areas in which they can be applied.

Peculiarities

Phillips-head screws are threaded along the entire length of a metal rod and with a small semicircular head at the end, with a slot for a Phillips screwdriver. The head serves as a place for the transmission of torque from the tool. The slot located on its surface greatly simplifies the process of screwing in the fasteners.

All requirements for the quality, size and other parameters of such fasteners can be found in GOST 7048-2013.

Besides, the quality of products can be confirmed by the German standard DIN 7985. These types of screws provide a secure connection. They are universal fasteners, so they can be mounted both in prepared threaded holes and in smooth seats.

These Phillips screws are available in a variety of metals. But most often you can find models made of stainless steel. They are considered the most reliable and resistant to external influences. Often they make connections on structures that will be placed in the open air, since such a metal base is not afraid of temperature extremes and humidity.

Some samples are made from brass or plain steel.

All these materials are additionally coated with special protective solutions that prevent the formation of corrosion on the surface.

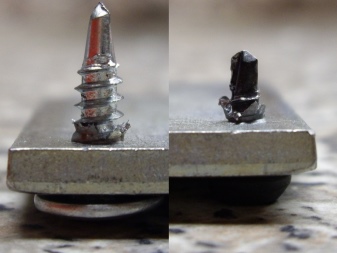

As a rule, such models are self-centering, which prevents the working part of the Phillips screwdriver from sliding off during the screwing process, so working with such fasteners is quite simple.

What are they?

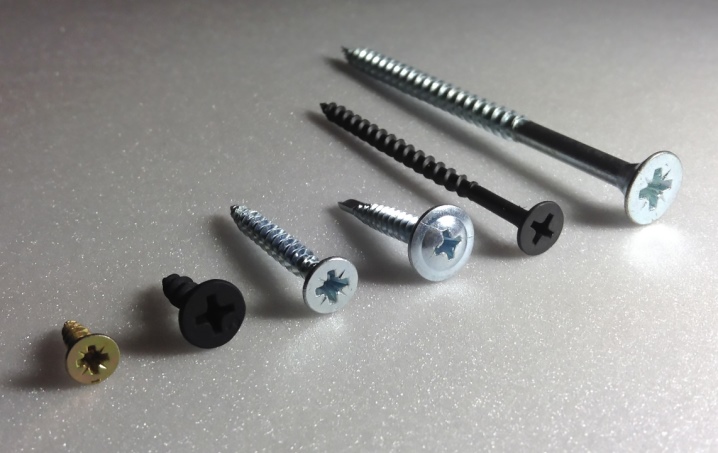

Phillips screws can be of various types. They differ depending on the type of head. Among them are the following models.

- Countersunk head options. When screwed in, these products are hidden in the material. Such fasteners will practically not be visible, they will not spoil the appearance of the structure. Countersunk head samples are most often used when joining sheet materials of considerable thickness to metal frame structures. If you use this type of slotted screw, then you will have to pre-form chamfered holes on the surface of the material. They are made so that the plane of the head end is located at the level of the plane of the sheet base.

- Models with a semicircular head and a press washer. These types of Phillips screws are best used for attaching thin sheet materials to metal frames. Such fasteners, equipped with an additional press washer, protect the sheet structures from deformation and other damage at the attachment points, and also increase the contact surface between the materials to be fastened.

- Semi-cylindrical head models. Such fasteners can be used to attach and hang sheet metal structures to other metal framing materials. These elements allow you to provide an aesthetic appearance of the finished structure, they will not spoil the overall design.

- Half-countersunk head models. These samples for fasteners look similar to ordinary countersunk products, but the upper part is not completely flat, it is slightly rounded. The fasteners will fit into the materials to be joined, while a small part of the fixture will remain from the outside. A special plastic plug is put on it, it protects the metal from corrosion, in addition, this additional element hides the rest of the screw.

Screws differ from each other by the type of thread:

- Tapered metric threads are considered a popular option. Such products have a triangular profile.

- There are special thrust threads, in this case it looks like a trapezoidal profile.

- The round variety is used for screwsthat are subjected to high dynamic loads.

These types are rarely used to create cruciform fasteners.

Also, the screws may differ depending on the type of protective coating:

- Zinc coating. Many models are produced with a special galvanized coating.

It perfectly protects fasteners from corrosion and weathering.

The zinc coating can be black or yellow. The first option is less resistant to corrosion. The highest resistance is shown by yellow chromating.

- Nickel plated will be able to protect steel products only from mechanical damage. However, it will not provide resistance to the appearance of a corrosive layer. Often, in the manufacture of such screws, special phosphating is used, it is used only if it is not required to give a decorative appearance to the fasteners. Products are thoroughly treated with special chemical compounds, as a result of which a phosphate film forms on the surface, which protects the metal.

Phosphating also creates an additional layer that protects against moisture.

Parts processed in this way can be dark gray or black.

- Oxidation is also one of the ways to handle metal fasteners. This procedure is carried out by applying an oxide film to the surface of the parts. In terms of its characteristics and properties, such a coating is close to phosphated. Oxidized screws are available in dark gray or high-gloss black.

Such elements have good adhesion and anti-corrosion properties.

Phillips screws may vary in size and weight. The standard values are M6x10, M6x20, M6x12, M8x12, M8x16, M8x20, M8x30. But in hardware stores, buyers will be able to find models of other sizes.

Applications

Phillips head screws can be used to connect different materials. These parts are used not only in the process of carrying out various installation, repair work, they often find their application in agriculture, mechanical engineering, industrial industry.

Depending on the type of thread, such models can be taken for installation in blind or through holes. Phillips screws will be able to provide a durable and strong connection between parts.

The comment was sent successfully.