Trapezoidal screws: characteristics and applications

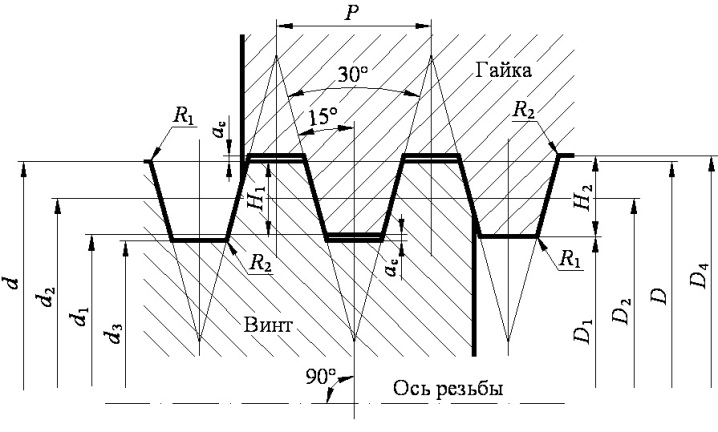

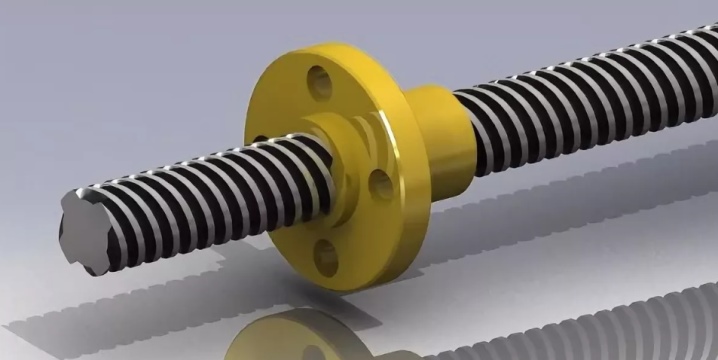

Trapezoidal threading is a special type of thread that uses a non-standard profile that resembles a trapezoid in its external shape (hence the direct name of the process). To carry out production work of this kind, special trapezoidal screws are required. Today in our article we will talk in more detail about the features and distinctive characteristics of such elements.

Characteristic

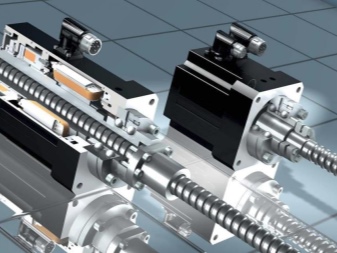

Traditionally, the trapezoidal screw is not used by itself, but is paired with a specially designed nut. These elements represent a travel drive that ensures the implementation of the thread. A pair of screw and nut has a sliding-friction force. If we talk about the running gear from a production point of view, then it should be noted that its direct purpose is the transformation of rotary motion into translational motion.

A pair of screw and nut is most often used to provide even and stable straight motion.

Screws are very demanding in terms of maintenance - they must be kept clean at all times. This fact makes the maintenance of the mechanisms, of which the trapezoidal screws are a part, quite costly and laborious. However, the trapezoidal thread can serve for quite a long time, and it works very quietly, without causing any inconvenience. And also these screws are characterized by increased carrying capacity.

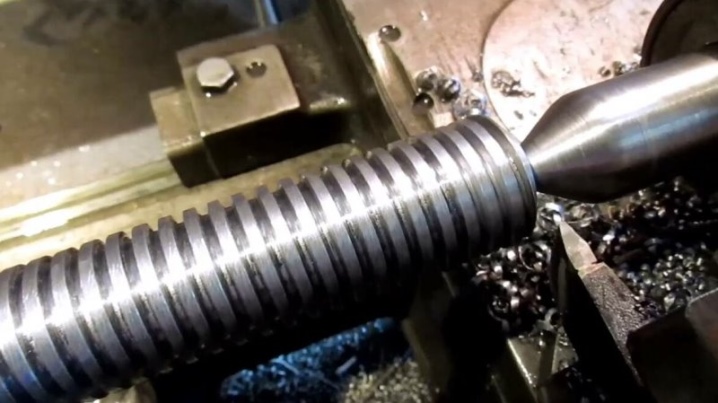

The production of trapezoidal screws is a long and complex process. In this case, the thread rolling technology is mandatory. Thanks to this technology, the thread becomes as smooth as possible. The distinctive characteristics of this type of screws include the fact that they have a special and rather specific self-locking property.

Today, a large number of both domestic and foreign manufacturers are engaged in the production and release of trapezoidal parts.

Views

Today, in the modern market of technical devices, components and accessories, you can find a large number of different types of travel gears in the form of a trapezoid.

For example, depending on your needs and desires, you can purchase trapezoidal elements with or without machining. In addition, many manufacturing companies carry out machining of parts according to individual customer orders.

Thus, unprocessed varieties are also often called katanas. They can be of different accuracy classes, the most popular of which is C8.

Machined parts are more widely available on the market, and they can have a wide variety of sizes.

Dimensions (edit)

According to GOST, there are several sizes of trapezoidal screws. Each of them is necessary to perform certain tasks. Consider the most popular and common dimensional indicators:

- 14x2 mm;

- 30x6 mm;

- 10x2 mm;

- 12x3 mm;

- 12x4 mm;

- 14x3 mm;

- 14x4 mm;

- 16x4 mm and others.

The size of the part should be selected according to your individual needs and requirements. At the same time, think over and determine the scope of use of the parts in advance, so as not to regret the purchase made in the future.

Usage

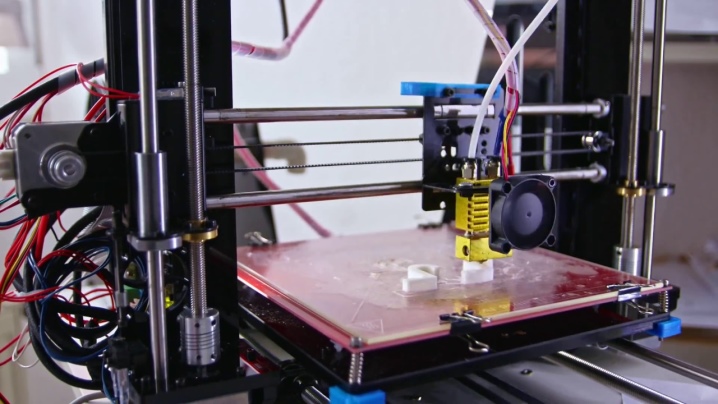

I must say that trapezoidal screws are elements that are used in a wide variety of areas of human activity. The implementation of many processes is impossible without them.For example, trapezoidal screws are used in mechanisms and devices such as 3D printers, milling and turning machines, numerical control and many other areas. In addition, they are integral elements in such devices, the operation of which is directly associated with low speeds of rotational motion.

More generally, trapezoidal screws are parts without which trapezoidal threading is impossible. This technology is actively used in the process of feeding movements on lathes, for moving lifting devices and products on assembly containers, as well as for moving press structures in the vertical direction.

If we talk about other spheres of human activity that simply cannot exist and develop without trapezoidal threads (respectively, without trapezoidal screws), then they include the automotive industry, steam locomotive construction and other industrial areas of mechanical engineering.

How to choose?

The choice and purchase of trapezoidal screws should be approached as responsibly and carefully as possible. The thing is that the overall quality of the work of a particular mechanism depends on these details. Experts recommend focusing on several key factors:

- material of manufacture (give preference only to those screws that are made from high-quality, durable and reliable raw materials);

- type and size (these parameters are individual characteristics of screws, the choice of which should be approached based on the specific needs of a particular person);

- manufacturer (it is important to pay attention to the brand and choose only those products that were produced by well-known manufacturers);

- place of purchase (to purchase trapezoidal screws, contact only official stores and dealerships);

- reviews (so you can understand whether the properties and characteristics declared by the manufacturer correspond to the real state of affairs);

- cost (choose products from the middle price category, as they correspond to the optimal ratio of price and quality).

Guided by these rules, you will be able to choose the screws that will meet the highest quality level, will last a long period and will meet all the individual needs of the buyer.

For how to cut a trapezoidal thread, see the next video.

The comment was sent successfully.