Features of plastic dowels

Various types of dowels are widely used in construction. These devices act as reliable fasteners for fixing structures made of various materials. Currently, there are a huge number of different models of these elements. Today we will talk about what features plastic dowels have and what sizes they can be.

Characteristic

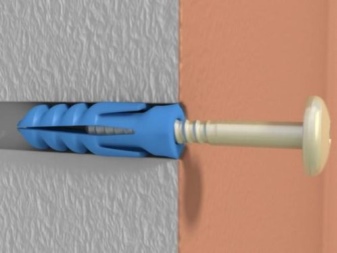

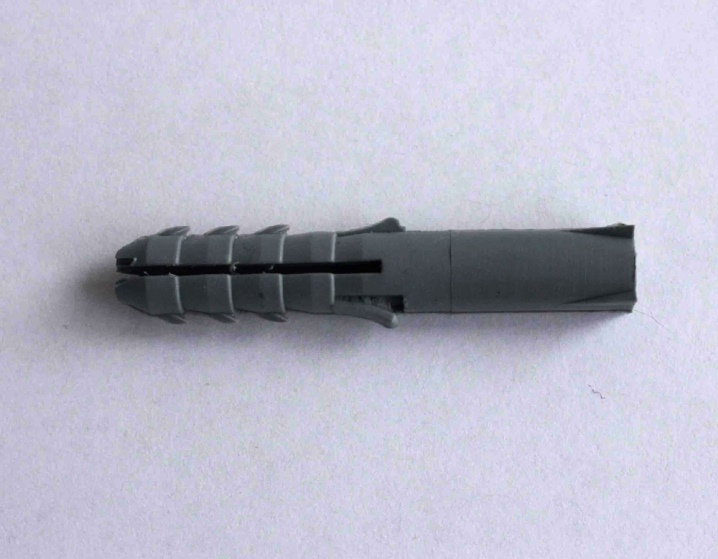

Dowels made of plastic look like ordinary nails. As a rule, they are installed at the base of products for the installation of other fasteners in them, including a screw or self-tapping screw.

Plastic dowels include two parts.

- Non-controversial part. This component does not actually participate in consolidation. It looks like a small base of the device itself.

- Spacer part. This component is the main one. It is she who provides fixation, changes its size during the formation of connections.

Such plastic fasteners sometimes have a special cuff. This additional element is a border around the hole. It prevents the tool from falling into a hole made in the material.

Plastic dowels hold significant loads well.

They can be used for different types of designs. So, there is a separate type of facade models. They are most often available in blue or orange colors.

Dimensions (edit)

In hardware stores, you can find a large number of different plastic dowels. In GOST 26998-86, you can find a table with all the standard sizes of such devices.

Typical dimensions include the following values: 6x30, 6x40, 6x50, 6x60, 6x80, 8x60, 8x80, 8x100, 8x120. Dowels for special equipment (construction gun) can have dimensions: 4.5x30, 4.5x40, 4.5x50, 4.5x60, 4.5x80, 5x100.

Less common are plastic dowels with values of 5x15, 6x35, 10x80, 10x100, 10x60, 12x60, 12x70. When choosing the appropriate option, one should take into account the material from which the structure is made, in which it is required to make recesses.

Varieties

Plastic dowels, depending on the type of spacer, are divided into eight varieties.

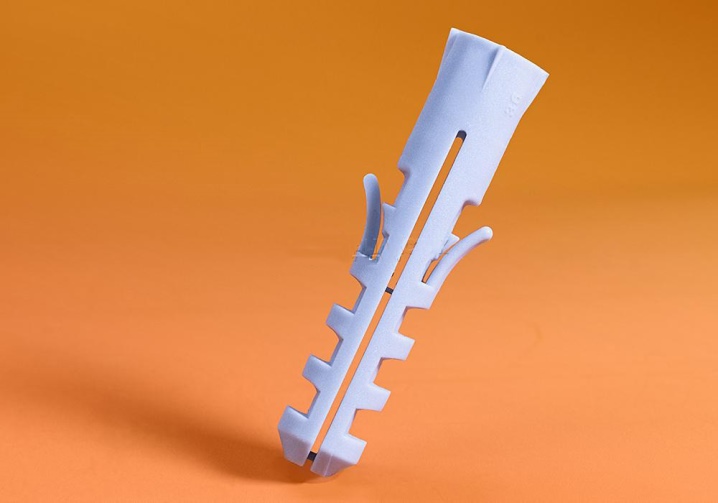

S - universal

This type has a sleeve, which is equipped with special teeth. By contracting, they provide better friction. In addition, they have special locking tongues that prevent the fasteners from turning too much during the installation process.

K - studded

This model is considered the most popular type. It has a small spacer part. Products of this type are equipped with an extended front part. Small spikes are provided on the sleeve, which provide the most tight contact between the device and the material.

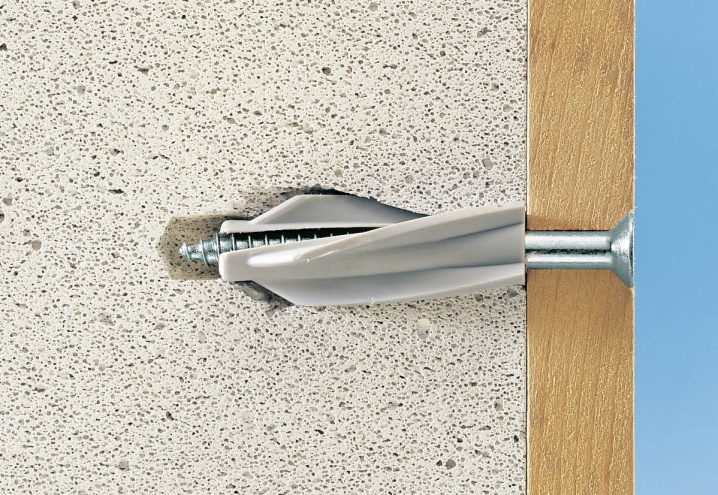

N - four-spreader

The model provides the most uniform distribution of pressure on the walls of the recess... It is this variety that has a special bearing capacity. Products perfectly hold even a large load, they are often used when fixing concrete surfaces.

T - three-lobed

This variety is used for brick and concrete, as it can withstand significant loads. In the process of screwing in, its sleeve will gradually expand, while the petals will slowly press against the walls of the recess made. Most often, a plastic chopik is inserted into the material using a screwdriver, since it is rather difficult to scroll it.

U-shaped

This variety is considered universal option for securing. It can be used to fix both solid and hollow products. There are three special petals on the sleeve of the product, which, when in contact with concrete bases, significantly increase the friction force.

"Butterfly"

This type of dowel is used to fix sheet materials, including for thin wooden panels, drywall. The material should not be more than 10-12 millimeters thick... Such fasteners, passing through a thin surface, fold and press against the back of the base.

Chopik for foam concrete

There are small ribs on the retainer sleeve, which change their direction during operation. During screwing in, the sleeve begins to gradually expand, while the ribs form a single whole with the material.

"Piranhas"

These varieties are considered the best option for fixing chipboard sheets, brick base and panel products. There are special reverse-directed teeth on the product sleeve. Such a structure allows for maximum structural durability.

Production

Currently, there are a large number of manufacturers that produce plastic fasteners in various sizes. The most popular among buyers are six companies.

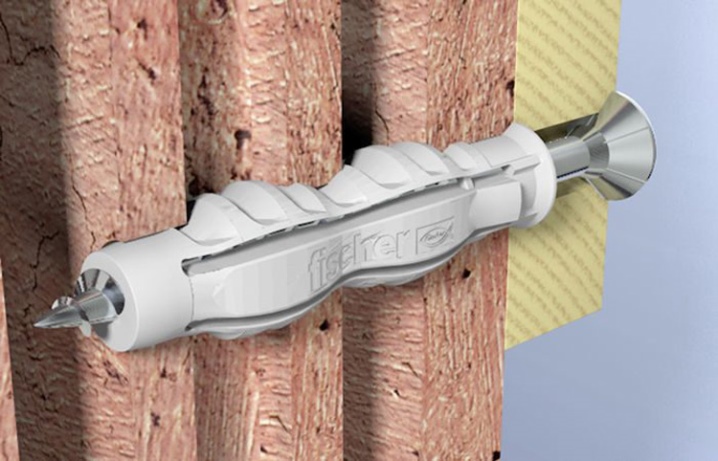

Fischer

This German company specializes in the production of universal clamps. They are most often sold in sets of 50. These fasteners provide a strong hold on the elements.

Mungo

This Swiss manufacturer supplies facade-type dowels to Russia. They are available in two different versions. The first option is painted in a bright orange color, it is distinguished by an increased value of fire resistance. All of them are equipped with special electro-galvanized spacer screws. Their length can vary from 60 to 300 millimeters.

Termoclip

Fasteners of this Russian company are most often used to create thermal insulation systems. The brand produces different types of fasteners: mushroom dowels, disc dowels. Most of these models are created in bright crimson colors.

Tech-Krep

This Russian company also specializes in the production of thermal insulation clips. There are several main types of such fasteners. Popular options are models with a metal and plastic nail and samples with a special thermal head. The company's products are manufactured using a complex chemical composition, which ensures maximum flexibility and precision in the shape of the products. These plugs can be 8 or 10 millimeters in diameter.

Koelner

The company produces a large number of mushroom dowels for insulation. Their diameter can be 8 or 10 millimeters. The materials from which the products of this company are made undergo special processing, after which they become much more shock-resistant. These fasteners are painted gray-white.

Features of choice

Be sure to look at fixture size. The choice will depend on the thickness of the material itself. The element must not protrude from the back side. Longer models should be selected for wood with a large thickness.

In addition, do not forget that some models of such fasteners are intended only for certain structures.

So, there are a large number of dowels for creating thermal insulation.

When choosing, pay attention to the quality of the product itself. There should be no cracks or bends on its surface. Otherwise, the fasteners will not be able to provide a fairly reliable fix.

Mounting methods

In order for the fastened structure to be able to serve for a long time in the future, all fasteners should be as firmly and correctly fixed in the materials as possible. So, first you need to drill holes in the base for planting the dowels. This can be done using a conventional drill.

Make sure it is not too big. Otherwise, the fasteners will not be able to properly fix in the material. After that, you need to clean the surface from the formed particles after drilling and from other debris.

Then you can start installing the dowel itself. To do this, it is recommended to pre-blow the hole made with an air stream (for this you can use a special pump), then the fasteners are driven in. This should be done as carefully as possible, because plastic models are more flexible and plastic, during operation they can be severely damaged.

At the final stage, it is necessary to screw the dowel into the hole. To do this, you can take a screwdriver or a simple screwdriver, depending on the strength and hardness of the material.

If you are mounting double-spaced fasteners, then you should pay attention to the location of all plastic chops.

Such varieties should be placed in the foundations in the direction of the load.

The types and features of plastic dowels are described in the video.

The comment was sent successfully.