Features of mounting dowels

Installation work is one of the construction stages. To carry them out, you need to have special equipment, tools and materials, both basic construction and consumables. The latter, without which it is completely impossible to mount any structure, include fasteners, including dowels.

In this article, we will tell you everything you need to know about mounting dowels, consider their technical characteristics, types and sizes, and learn how to choose the right fasteners and perform the installation correctly.

Specifications

An assembly dowel is a special element that is used in the process of quickly connecting structures.... The dowel-nail today is one of the most popular and frequently used fasteners in construction. This is due to the numerous advantages and features of the product.

The dowels have the following technical parameters:

- strength;

- reliability;

- mechanical stability;

- wear resistance and corrosion resistance;

- light weight - although the product weighs little, it does an excellent job with its functions and can withstand heavy loads;

- heat resistance.

If you choose the right dowel, taking into account all the technical parameters and properties, and mount the fasteners in accordance with the requirements and rules, it will function for a long time, and its initial characteristics will remain unchanged.

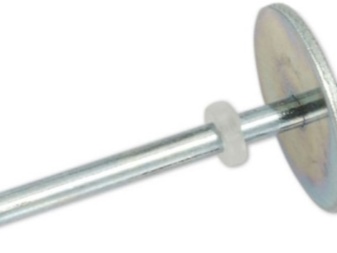

The design of the mounting dowel differs little from the structure of other dowels. Its main components are a spacer part, which expands inside the hole to ensure a strong and reliable fixation, and a steel nail. There are kit models equipped with a special limiter - a cuff.

For the manufacture of the spacer, the following materials are used:

- polypropylene;

- polyamide;

- polyethylene.

The nail is made of high strength steel. It is coated with a special compound based on zinc. Such a coating enhances the physical and technical properties of the fasteners and extends its service life.

Absolutely all information about such a product, namely, technical parameters, properties, methods and methods of manufacturing, operating rules are provided for by the normative document GOST 28456 - 90 “Expansion dowels for construction and assembly. General technical conditions ".

Types and sizes

Another rather significant advantage of mounting dowels, which significantly affects demand, is a large assortment... There are many sizes of fasteners. This makes it possible to choose the one suitable for a particular type of installation.

The most popular are the following dimensions (in mm):

- 10x130;

- 10x132;

- 10x150;

- 6x40;

- 6x60;

- 5x60;

- 8x80;

- 8x100.

For a certain type of installation, you need to choose a dowel of a special size. For example, when it comes to fastening a structure to a concrete or brick base, you need to choose a product with a large diameter and length.

Each dowel size, in addition to all of the above, clearly spelled out in GOST... The document also contains the rules for the operation and use of each type of product.

All mounting dowels are divided into two types: threaded and unthreaded.

Their main difference is the installation method.... A threaded dowel can be screwed into the hole using a screwdriver, but to install a threadless dowel, you need a special tool called a gun.

Selection rules

The final result depends on how correctly the fasteners are selected. It is very important to approach the selection of a product responsibly and take into account:

- physical and technical properties and parameters of the product;

- its purpose, and what material will be used for fastening;

- under what conditions it will be used;

- what load will need to withstand;

- who is the manufacturer of the product and its cost.

Also, when buying, you need to pay attention to the presence of marking. This is a mandatory "stamp" on each product, which was manufactured in accordance with the requirements of GOST, passed all the necessary laboratory tests and received a quality certificate. The dowel markings are two sizes: diameter and length.

As for the choice of the manufacturer, experienced specialists, who have been engaged in installation work for more than a year, recommend buying products from well-known brands, whose products have long been on the market and have proven themselves well.

Application

Today, in many areas of activity, it is the mounting dowel that is used. This is facilitated by the excellent characteristics of the product. It is used both in large industrial enterprises and factories, and in everyday life. The fastening element is often used during assembly and installation:

- window and doorways;

- skirting boards;

- brackets;

- hoods, kitchen cabinets, household appliances, furniture;

- floor covering;

- water heaters and heating devices;

- electrical wiring;

- plasterboard partitions and ceramic tiles.

Mounting dowels, which are characterized by high strength, are also commonly used in the process of installing facade panels and other elements of the facade of a building.

This fastener is so versatile that it can be used to attach absolutely any structure to various types of bases: concrete, stone, brick, wood, plastic, plasterboard.

The following video talks about dowel nails.

The comment was sent successfully.