All about confirms

Furniture hardware, called a confirmat, is very popular due to the fact that it is quite easy to assemble, while it needs preparatory (especially accurate) marking and drilling of a bore hole. In order to accurately mark the landing site for the confirmation, a special device is used in the form of a confirmation drill, and in production conditions, in the manufacture of furniture, the holes are made on a drilling machine.

The name of the hardware comes from the German word confirmat, as this product was developed by German specialists. Furniture hardware first came to the USSR in 1973, when an international exhibition was held in Moscow. The confirmation received widespread use only in the 90s and since then has been widely used in the manufacture of furniture products.

What it is?

The furniture confirmation has another name - the Euro screw, it is made of an alloy with the addition of a zinc coating, so the hardware looks shiny and attractive, and most importantly, it does not corrode.

The production of furniture hardware is established in Russia, and today it is one of the most demanded products, without which it is impossible to imagine the assembly of modern furniture of any type.

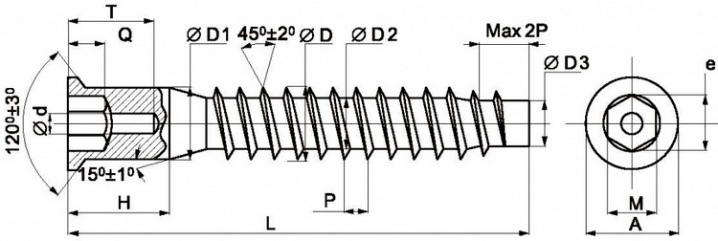

In appearance, the confirmat looks like a small self-tapping screw, equipped with a thread, thanks to which it has the ability to be screwed into the end part of the furniture blank. The confirmat has a leg and a flat head, on which slots are made for a Phillips or hex screwdriver. Most often, it is the hexagonal notch that can be seen on the cap, while the slots for the cross are very rare. The core part of the hardware, in addition to the thread, has a blunt end, therefore, in order to install the confirmat into the cavity of the furniture blank, preliminary drilling of the bore hole will be required.

Certain features are characteristic of the furniture Euro screw.

- Thread on the leg of the hardware quite massive, and the edges of such a thread have a wide projection relative to the axis of the leg. In the lower part, there are several turns of a conical type with a small notch.

- Confirmation rod has a fairly large area, which allows you to evenly distribute the load on the connected furniture parts, therefore, the finished product (after assembly) has a high degree of stability during operation.

- Euro screw has the same diameter of the rod and the smooth part, this allows the hardware to be reliably and tightly held in the thickness of the material fixed with it.

- All Euro screws are made only of high-strength carbon steel and have an anti-corrosion coating, which can be made of zinc, brass or nickel. The most common are galvanized silver confirms.

- The product is a Euroclass hardware, therefore, it is subject to production only in an industrial environment, and is also subject to quality control, which is reflected in the certificates.

The furniture Euro screw, like any product for connecting purposes, has both its advantages and some disadvantages.

Positive sides:

- hardware is quite simple to mount not only in industrial, but also in domestic conditions;

- the flat head of the European screw allows you to connect parts in series, one after another;

- to fix furniture blanks with a confirmat, no special equipment is required;

- hardware is able to firmly and reliably attract parts of the furniture structure to each other;

- materials, connected to each other by a Euro screw, are able to withstand many cycles of significant loads during operation.

Negative sides:

- when two furniture pieces are connected, a flat metal head of the confirmation will be visible on the surface, so it has to be covered with special plugs made of plastic, similar in color to the shade of the furniture;

- It is not recommended to disassemble the assembled furniture parts, since after such a procedure the connection becomes unreliable, and the very design of the confirme's thread does not withstand repeated screwing and unscrewing.

Since the Euro screw is made of high-strength steel, the product has a certain degree of flexibility - the confirmation may slightly bend, but it does not break, which gives the furniture structure a certain degree of plasticity.

Comparison with self-tapping screws

In terms of its structure, the furniture confirmation is outwardly similar to an ordinary screw, but differs from this hardware in that it has a larger diameter and a larger stepped thread. This feature allows the Euro screw to increase several times the area of contact with the fastened part inside the mounting hole, which, in turn, gives the connection of furniture parts strength and durability. It is believed that according to the strength of the connection, 1 confirmat is equal to 4 screws, if we take hardware of the same length and diameter.

Especially high-quality connections with the help of confirmation are obtained when working with laminated chipboard, where the core of the material is a loose sawdust composition mixed with an adhesive mass. If a thin screw is introduced into the thickness of the chipboard, then it will not be able to firmly and reliably fix there, and the Euro screw (due to its large contact area) is also able to capture denser layers of material, reliably strengthening and creating a fixed connection. For this reason, when assembling furniture structures, preference is given to European hardware.

Confirmations are often compared with self-tapping screws, but this approach is not entirely justified, since there are fundamental differences in working with these hardware.

Drilling a bore hole for European hardware will require a certain amount of time and effort, but all these labor costs are paid off by the fact that as a result of using such a tie, a strong connection of furniture parts is obtained that can withstand operational loads.

As for self-tapping screws, it is not necessary to make a bore hole for them, since this hardware has the ability to independently screw into the thickness of the material, which greatly simplifies working with it. But a self-tapping screw does not provide such a reliable fastening and simply fixes 2 parts to each other, not ensuring their adhesion strength under loads. If the furniture is not intensively used and disassembled, then the self-tapping screws will cope with their task, but if you have to disassemble the product at least once, then instead of the self-tapping screw, it is more expedient to use a confirmation.

The fact is that when screwing in, the self-tapping screw cuts a new hole for itself, and when it is re-mounted there is no guarantee that the hardware will go along the old hole, and not cut itself a new one, thereby weakening the attachment point in the structure.

Description of species

The European flat head screw is applied to furniture and is a reliable fastening of furniture construction parts. Especially often this hardware is used for laminated chipboard, assembling the frame, or as an installation for hinges. Often, the confirmat is also used for fastening the cable, when installing a cable channel with an internal arrangement of fasteners.

Modern industry produces several types of furniture screw hardware:

- furniture screw for a hexagon with a corresponding head;

- furniture screw with a square slot.

By external signs (depending on the type of head), they are distinguished:

- hardware with a secret type of head;

- hardware with a semicircular head type.

In the furniture industry, in the manufacture of products, all types of euro screws are used, since today it is the most durable and reliable type of hardware, with the help of which both solid wood parts and products made from woodworking products are connected: MDF, chipboard, plywood, laminated chipboard etc.

main parameters

Euroscrew has the ability to connect furniture parts, the thickness of which does not exceed 16 mm. To make a bore hole, the easiest way is to use a special confirmation drill, and a key designed for a Euro screw is used to fix the hardware. The connection of furniture structures requires accuracy and a certain skill in the work. An important step is the correct choice of the size of the hardware and the calculation of their quantity.

Dimensions (edit)

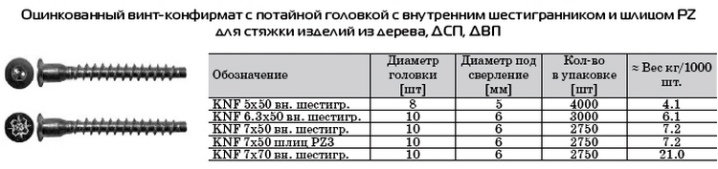

The European screw has a standard size range, the dimensions are recorded in the form of numbers, where the first indicates the diameter indicated in millimeters, and the second indicates the length of the hardware (also in millimeters).

|

Working rod diameter, mm |

Working rod length, mm |

|

5 |

40; 50 |

|

6,3 |

40; 50 |

|

7 |

40; 50; 60; 70 |

As practice shows, for the assembly of furniture structures, hardware is most often used, which have a dimension of 6.3x50 mm or 7x40 mm.

The weight

In Russian specialized retail outlets, hardware is sold by weight, so when buying these materials, you should know that the price will be indicated for 1 kg. The total number of hardware required for screeding of furniture elements depends on the fastening area.

To make it easier to navigate in determining the quantity, there is data on how much 1000 pieces weigh. Euro screws of various sizes.

|

Hardware diameter, mm |

Weight of 100 pieces of hardware, kg |

|||

|

length 40 mm |

length 50 mm |

length 60 mm |

length 70 mm |

|

|

5 |

4,5 |

5,48 |

- |

- |

|

6,3 |

7,1 |

8,2 |

- |

- |

|

7 |

7,3 |

9,1 |

14,1 |

21,1 |

All confirmations issued in Russia must comply with international standards and requirements 3E120, 3E122.

The most popular and popular is Eurometiz with a flat head for a hexagon, for the installation of which a special key with six faces or a screwdriver bit is used, which ensures reliable tightening of the screw in the plane of the wood furniture board.

Installation features

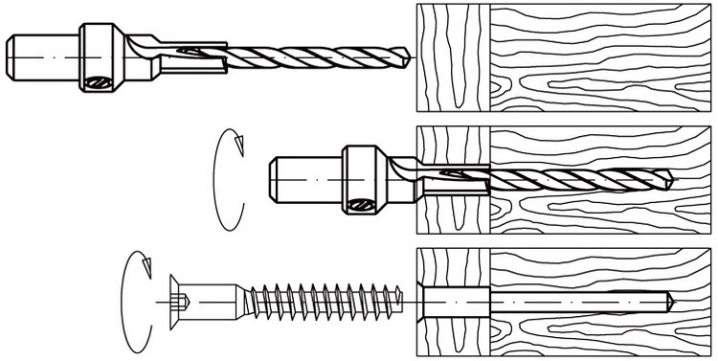

The European confirmation can be used for any type of chipboard. The essence of the formation of a fixed connection is as follows: a bore is made using a confirmatory drill, and the diameter of the device must correspond to the size of the selected hardware.

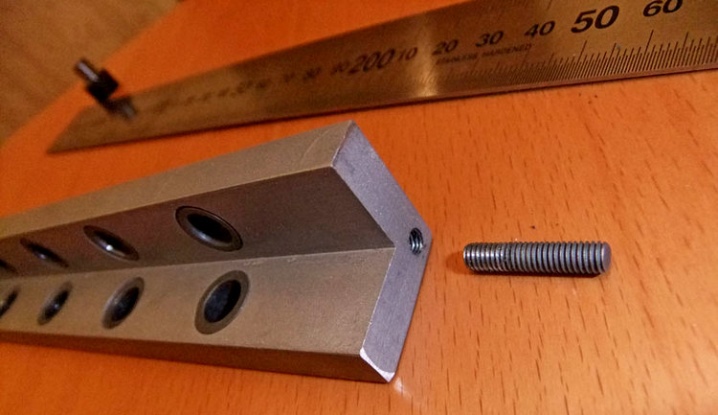

For ease of marking (before you start drilling), special templates or so-called jigs are used. - these are blanks that have ready-made holes and are superimposed on the surface of the furniture part in order not to take measurements once again with the marking of the place for planting the Euro screw. Such templates are made independently from improvised wood material or metal, but you can also purchase them ready-made.

After the bore hole is ready, you need to correctly install and tighten the furniture hardware, while its threaded part is located in a thinner, blind hole, and the head and a small, expanded, smooth part of the screw located below are in the upper part of the finished hole. After it was possible to screw the Euro screw into the cavity of the furniture material, a plastic plug is used, which will close the flat steel head of the hardware and make it invisible.

When making a hole for the confirmation, it is necessary to observe the minimum distance between the edge of the furniture piece and the axis of the European screw. This distance should be equal to double the depth of the bore, since the fastening parts are not installed very close to the edge due to the weakening of their reliability during operation.

When drilling a bore, it is advisable to use an electric drill or screwdriver at the fastest possible speed, as a result, smooth and precise indentations are obtained, and when screwed in, the hardware easily enters the drilled cavity and does not scroll during installation.

Possible problems

In the process of work, some people face the problem that the confirmat is scrolled and cannot fully go into the drilled hole, while its flat head protrudes from the surface of the material by about 1–2 mm. Most often, this situation occurs if the hole for the euro screw is not made with a special confirmation drill, but 2 conventional drills with different diameters are used. For example, a European screw is selected that is 7 mm in diameter and 50 mm in length. For the bore hole, wood drills are chosen: the diameter of one of them is 5 mm, and the other is 7 mm. With a drill, the diameter of which is 5 mm, a blind hole is made to a depth of 50 mm, then a 7 mm drill is taken and a small depression is made for the wide part of the cabinet. Despite the fact that the Euro screw does not rest against the bottom of the deep hole, it is not possible to screw it flush with the plane of the furniture blank.

In this case, experts recommend performing a wider counterbore under the head and the smooth part of the European screw, for which they take a drill with a diameter of 8 mm. When screwing in the hardware, a slight backlash will appear, which will make it possible to tighten the Euro screw close to the surface of the workpiece.

If such a countersink is not done, then when the confirmation is tightened, many cracks or chips of chipboard material may appear near the hole, such a defect can no longer be eliminated with a plug attached to the screw head - the furniture product will be damaged.

For more information on confirmations, see the video below.

The comment was sent successfully.