All about fasteners wood grouse

Construction, like repairs, is almost impossible without the use of screws. In order to securely fasten wooden structures and parts, a special type of hardware is used - wood grouse. Such fasteners are characterized by reliable fixation, therefore they are often used during the installation of various wooden elements.

What it is?

During repair work and construction, it is often necessary to install wooden structures with high bearing loads. In order for the fasteners to be carried out correctly, the craftsmen recommend using wood grouse screws, which may have a square or hexagon-shaped head. This product is made of high quality galvanized coated stainless steel.

The wood grouse fastener is equipped with an external thread, which, when screwed in, forms an internal thread in a wooden hole. Thanks to this feature, a durable and high-quality mount is obtained.

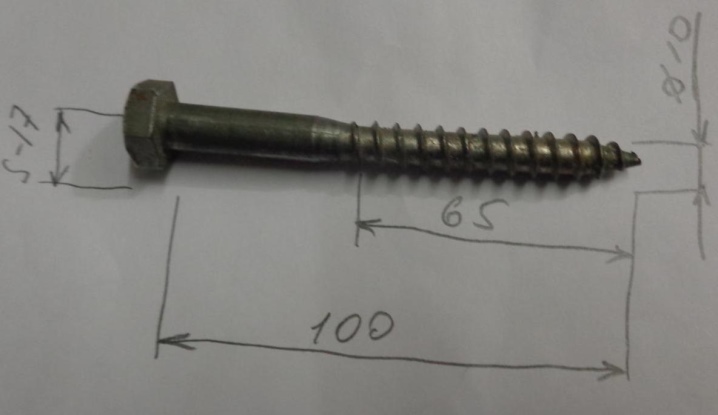

A plumbing bolt can have different rod lengths and head shapes. This self-tapping screw has a stamp with information about the manufacturer and the characteristics of the product. The rod consists of 2 parts:

- smooth, in the form of a cylinder;

- with external thread.

The end of the self-tapping screw is represented by a sharp tip, thanks to which the hardware easily enters the wood. Capercaillies have found their application when it is necessary to fasten structures made of wood with high bearing capacity. These hardware fasten slats, boards, bars to a brick and concrete base. It is difficult to do without hexagons when installing plumbing fixtures on a wall or concrete floor. In addition, this fastening connection is used in mechanical engineering, when working with rails and concrete pillars.

Varieties

The metal screw wood grouse is of the following types.

Anchor

This product is characterized by a single-start thread and a small profile height. The rod of this model is equipped with a sharp and rather strong base.

Capercaillie is usually used when it is necessary to fix boards to dense wood products.

Hardware is quite in demand in the furniture industry, namely during the creation of structures from red wood varieties.

Facade dowel with long metal rod

At the heart of the manufacture of a screw is an alloy of high strength metals. A screw thread is located along the entire perimeter of the wood grouse, therefore the self-tapping screw is indispensable during the assembly of the profile facade, as well as door and window structures.

Threaded rod

Such wood grouses are considered to be among the best. Thanks to their use, craftsmen have the opportunity to combine wooden products with large dimensions. Models of self-tapping screws with threaded rods are characterized by the presence of a strong metal base and deep threads. There is a cross-shaped notch on the screw head.

Currently on the market you can find wood grouses who have the following type of hat:

- conical;

- secret;

- loopback;

- rod;

- flat;

- hemispherical;

- biscuit.

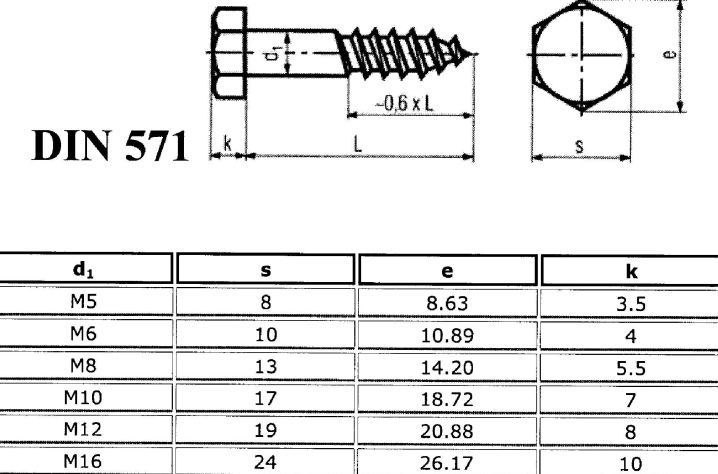

Dimensions (edit)

Plumbing wood grouse is available in a wide range of sizes. On sale there are products with different dimensions, for example, 8x35, 10x40, 12x 60 mm and many others.

Due to the wide variety of sizes of these screws, the master has the opportunity to choose the hardware that is ideal for the task.

Wood grouse size chart

|

Number |

Diameter 6, mm |

Diameter 8, mm |

Diameter 10, mm |

Diameter 12, mm |

|

1 |

6*30 |

8*50 |

10*40 |

12*60 |

|

2 |

6*40 |

8*60 |

10*50 |

12*80 |

|

3 |

6*50 |

8*70 |

10*60 |

12*100 |

|

4 |

6*60 |

8*80 |

10*70 |

12*120 |

|

5 |

6*70 |

8*90 |

10*80 |

12*140 |

|

6 |

6*80 |

8*100 |

10*90 |

12*150 |

|

7 |

6*90 |

8*110 |

10*100 |

12*160 |

|

8 |

6*100 |

8*120 |

10*110 |

12*180 |

|

9 |

6*110 |

8*140 |

10*120 |

12*200 |

|

10 |

6*120 |

8*150 |

10*130 |

12*220 |

|

11 |

6*130 |

8*160 |

10*140 |

12*240 |

|

12 |

6*140 |

8*170 |

10*150 |

12*260 |

How to use?

When working in wooden housing construction with wood grouses and screws that have gaps, it is worth following certain recommendations and doing the work correctly. To ensure a high quality connection, it is initially required to level the wooden surfaces. Experts recommend, if possible, to fix the clamps, as they impede the mobility of the material.

The drill for the timber must be selected in such a way that its diameter is smaller than that of the hardware. Next, you need to make a hole through the materials to be processed. For screwing in a self-tapping screw, a wrench and a wrench are best suited. Insert the nut evenly so that the pressure is evenly distributed over the wood surface. After that, the hardware is carefully screwed in - otherwise it may break.

See below for capercaillie fasteners.

The comment was sent successfully.