Features and varieties of dowels

In the modern market, you can find a lot of fasteners, with the help of which tasks in the household and construction sector are solved. A special place among hardware belongs to dowels. Many firms produce this type of product and produce it in a wide range.

What is it and why are they needed?

A dowel is a special type of fastener that is used in the installation and connection of different types of surfaces and structures. Today they are sold in many varieties, each of which is designed for a specific material, it can be wood, stone, concrete. Often this hardware is used in the absence of access to the edge of the rod connection. It should be used when it is necessary to make a blind type of hole, for example, installing a cabinet or shelf in a room.

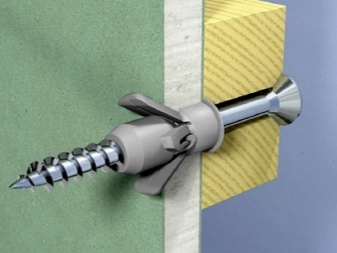

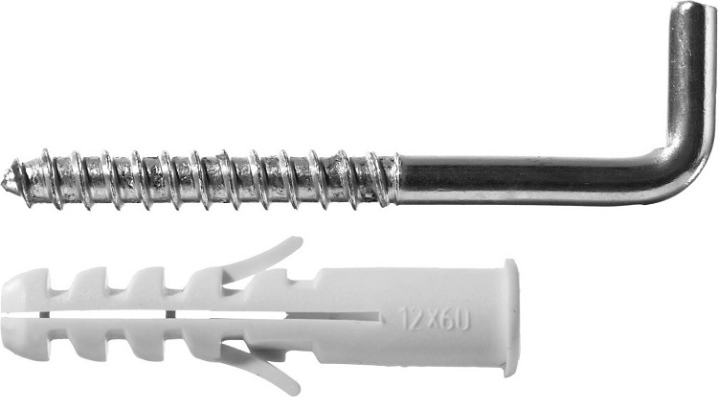

The dowel is considered to be a kind of buffer on the border of the wall and the screw. It is used to fix the structure due to the presence of special ribs, as well as holds. This hardware works on a spacer principle. A fastener of this type is in the form of a cylindrical bar. Its design consists of two parts:

- spacer, expanding during installation, and therefore reliably providing fasteners;

- not spacer, preventing contact of the metal base with the fastening material.

Some types of hardware have a cuff-limiter, which prevents it from falling through the hole. To enhance the expansion properties, various dowels may have additional elements.

- For locking products, they are represented by mustaches, spikes, ailerons. Their function is to prevent scrolling during installation.

- The spacers, have the form of various protrusions, spikes, teeth with different shapes and sizes. During screwing in, they form a tight contact with the walls of the hole and prevent the elements from being pulled out.

- The axial, they are represented by a kind of channels that preserve the axial direction of the sleeves.

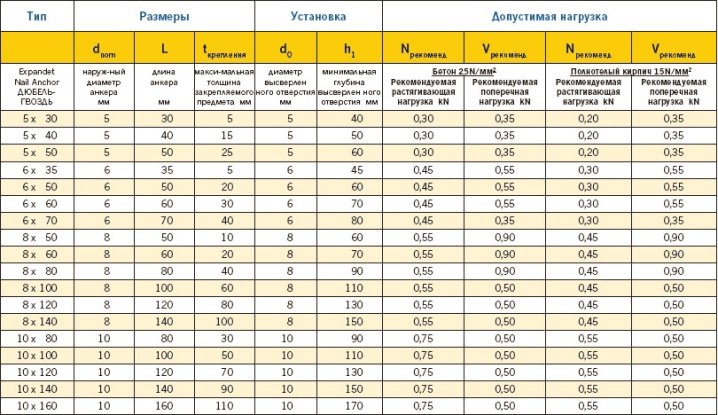

When choosing a dowel, you should focus not only on its appearance, but also on its size. In addition, the consumer needs to take into account the load that will be exerted on the product. The shorter the dowel length, the less loads it can withstand.

Each work surface requires the selection of the correct type of fasteners.

Description of species

Dowels are sold in a wide range and are in general availability for the consumer. In specialized stores you can buy a dowel-bolt, construction, "hedgehog", wedge, folding, spring, orange, dowel-screw, each of them looks differently. In addition, the key and the dowel are very popular.

Certain types of fasteners can be used to solve specific problems:

- fixing shelves, cabinets, wall and ceiling elements - universal screw hardware;

- installation of window structures, door frames, facades, roofs - special long-length dowels;

- thermal insulation of the facade and roof - dish-shaped product;

- installation of suspended products, for example, chandeliers, suspended ceilings - anchor fasteners;

- conducting cable channels - dowel clamps.

By area of application

During installation, it is worth considering not only the type of surface, but also the features of the fastened structures. According to these factors, dowels are divided into a number of categories.

- General purpose fasteners. Such hardware is considered to be all varieties for which the bearing capacity is considered an important factor. This type includes universal, nail, expansion dowels. The products can be used for all types of surfaces.

- Special types. Fasteners may have specific design features that limit the scope of their use:

- frame - these are devices for through installation, they are suitable only for metal-plastic profiles;

- disc-shaped ones are considered ideal for insulation with low load-bearing capacities. Thanks to their wide head, exceptionally soft material is retained;

- for drywall, presented in the form of butterflies and mollies, their sleeves are folded after pressing against the sheet only in a hollow material;

- The dowel clamps are equipped with special screws. With this model, only pipelines and cables can be fastened;

- with a metric type of thread, created only to work in conjunction with studs and bolts.

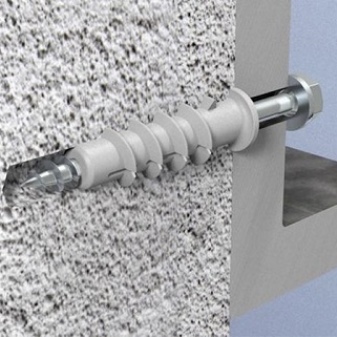

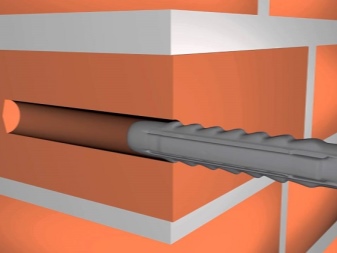

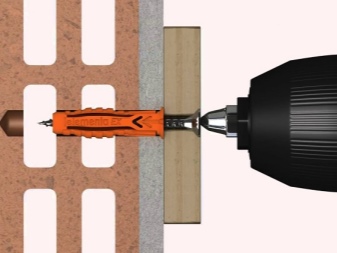

By type of base

Dowels are sold in a wide range, so they can be found in a wide variety of modifications, suitable for any material. The limiting factor for this attachment is the thickness of the material as well as the actual load. For dense materials, for example, a concrete tongue-and-groove slab or brick, hardware will be required, which will create a reliable fastening by pressing tightly against the wall. In this case, a high frictional force creates the maximum reliability of the connection.

Most types of dowels are suitable for solid material: expansion, universal, frame, facade, nail.

For hollow, hollow and loose materials, dowels are used, which form an attachment using a mold. Several such options are used.

- Universal. This type of product has a low bearing capacity, but it is usually sufficient for fastening to concrete, furniture, communications and equipment.

- For foam concrete a frame dowel is considered an excellent option. It has been used successfully for plastic structures. Since the product has a long length and a peculiar design, it is not suitable for solving other tasks.

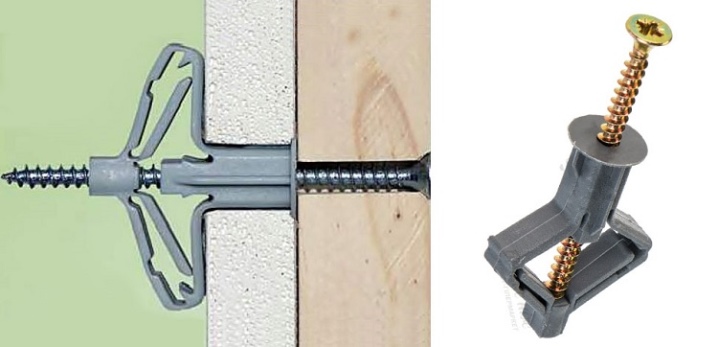

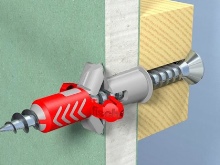

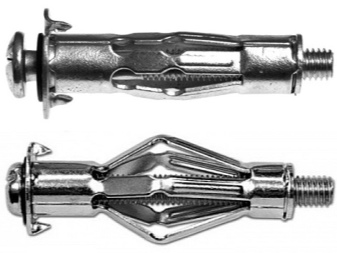

Also on sale you can find fasteners for sheet and panel products. The connection in this case can be formed due to the shape. This type of dowel has a through slot along its entire length.

While screwing in the hardware, the sleeve is folded, and due to the petals, an umbrella is formed, pressed against the steel or drywall.

The above features are typical for 2 types of products.

- "Molly". The material of manufacture of this device is galvanized and stainless steel. The working load for fasteners can be 12–75 kg. Rings and hooks usually come with such a device. This version of the dowel is considered the best for chipboard, wood, OSB, plywood.

- "Butterfly" has a design similar to the previous version. However, the material of its manufacture is plastic. This fastener is much lighter than "moth" and can withstand a load of up to 30 kg. "Butterfly" is well suited for skirting boards, fixing cornices, lamps.

Dowel catalogs have a huge number of varieties, so when choosing a product, the consumer may have some difficulties. To choose a fastener for foam, for plastic elements, gypsum base, for wood, under a screed, for plaster, for insulation, etc., it is worth considering a number of points.

- Base material. The same type of fastener used in different substrates will behave differently. Therefore, initially it is worth clarifying what the walls, ceilings, and floors are made of. Plastic and metal products have the same design and purpose, but differ exclusively in their bearing capacity. If the range is the same, then they can be replaced with each other.However, it is worth remembering that only metal products can be used in fire hazardous conditions.

- Load. In this case, it is necessary to correctly calculate the load and determine the required power of the hardware. The load can be horizontal shear and vertical, dynamic.

- Features of the product. Usually, special dowels are used for a specific type of product. Fastener models are often not interchangeable, but in some situations it is possible.

Manufacturing materials

Most of the dowels are made of plastic, since it is characterized by viscosity, elasticity, relative strength, and ease of deformation. The most affordable polymers for the manufacture of such fasteners are.

- Polyethylene. The material is characterized by lightness, resistance to acids. This dielectric does not rust, does not age or crack over time. Polyethylene is cold-resistant, so it can be used at temperatures of minus 40 degrees Celsius.

- Polypropylene. Compared to the previous material, it exhibits less resistance to cold. However, it is characterized by hardness and wear resistance. Polypropylene can crack and deform at temperatures above 140 degrees Celsius.

- Nylon. Polyamide is characterized by rigidity, strength, toughness, vibration resistance, as well as lack of sensitivity to mechanical damage.

The disadvantage of plastic dowels is their flammability. Iron dowels are characterized by strength and rigidity, they have little elasticity, toughness. Metal products do not deform, unlike plastic ones, having a high bearing capacity. Titanium, chrome, brass and even bronze hardware are also available.

A wooden dowel is relevant for fastening objects with low weight, it is a simple, cheap and reliable hardware.

Dimensions (edit)

It is not quite easy to describe the general sizes of dowels, since each manufacturer has its own production rules. However, according to GOST, the following values of fastening hardware exist:

- wooden products have a length of 5 to 100 mm, a diameter of 1 to 15 mm.

- dowel-nail is characterized by a length of 3 to 22 cm and a diameter of 0.5 to 1 cm.

- the dowel for the gun can have a length from 2.7 to 16 cm and a diameter of up to 0.5 cm.

Size table of popular types of dowels

|

Hardware name |

Length |

Diameter |

Thickness |

|

For drywall |

4-8 mm |

21–80 mm |

3-50 mm |

|

For thermal insulation |

8-16 mm |

90-400 mm |

40-150 mm |

|

Frame |

6–32 mm |

52-202 mm |

5, 6–31. 6 mm |

|

Dowel - clamp |

45 mm |

11-17 mm |

5-14 mm |

Mounting options

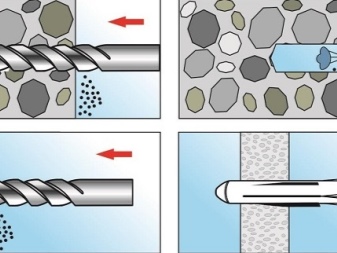

There are 2 types of dowels according to the type of installation.

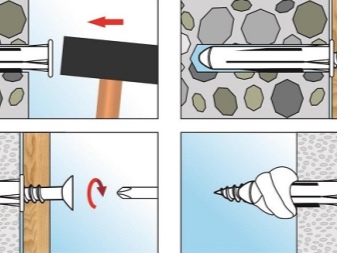

- Pre-installation. Fixation of the fastener takes place in the body of its base, the fastening material is loaded and stands firmly. Many types of dowels work according to this principle, for example, spacer, nail, universal.

- Through-fixing dowel. Before fixing on the base, the fasteners have to go through an intermediate material or a void, it can be fixed in a loose wall. This device has an elongated non-spacer section. Through-hole dowels include several types:

- frame goes deep into the wall, leaving a void at the border of the frame and the wall (for fastening metal-plastic structures);

- facade metal for insulation, powerful, of appropriate diameters and dimensions;

- roofing, produced in the form of a non-spacer sleeve, in the final part it is equipped with a hole;

- for insulation (with a large hat), it can be either spaced or non-spaced.

In addition, according to the fixing options, fasteners are of the following types:

- driven is considered the best option for aerated concrete, equipped with bent petals;

- twisted - it is installed in aerated concrete structures, and special teeth of hardware, pushing through the walls in the hole, then crimped, creating a strong fastening.

Currently, there are a significant number of varieties of dowels.Before starting the installation of any structure, it is worth deciding on the type of hardware to be installed.

The consumer should remember that with the wrong choice of the dowel, the fasteners can be pulled out of the wall.

The comment was sent successfully.