How to unscrew a broken tap?

The need to learn how to unscrew a broken tap arises for many craftsmen who are engaged in locksmith work, assembling mechanisms, and repairing them. There can be several ways to solve the problem. You can pull the broken off tap out of the blind hole with a drill, get it out with a reagent, or use other tricks.

How to pull out with a reagent?

Most often, when working with a tap, its tip remains in the hole, which is difficult to remove in the usual way. It is customary to make such elements from tool steel - a hardened material that at the same time becomes brittle, making it difficult to drill them.

When deciding to get a broken tap out of the thread in which it is stuck, you should first try to remove it using chemical reagents, by etching.

Step by step, this process will look like this.

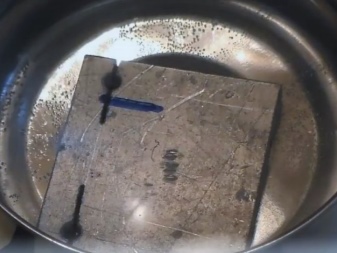

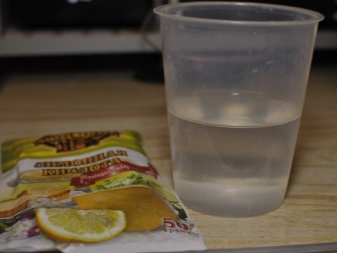

- Preparation of the solution. It is created from 10 g of citric acid and 200 ml of water. Mix the ingredients in a stainless container sized to accommodate the part with the stuck tap.

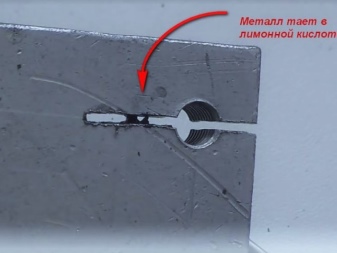

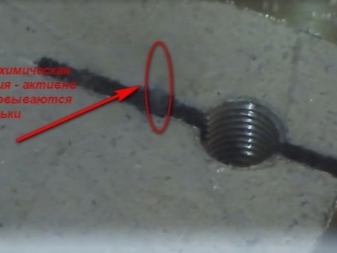

- Etching... The workpiece with the debris is immersed in a citric acid solution. The container is placed on the stove, under the lid, the liquid is brought to a boil - an increase in the temperature of the medium will become a catalyst for the chemical process. Then the fire is reduced to minimum values, the procedure takes 4-5 hours, periodically the liquid level is replenished. A sign of the onset of a reaction will be the appearance of small bubbles where the instrument is stuck.

- Retrieving... As the chemical processes proceed, the metal will dissolve, decreasing in volume. After 4 hours, the stuck tool can be removed along with the workpiece, cooled, and then removed mechanically by hitting the part with a hammer from the back side.

The whole process, from starting the preparation of the solution to solving the problem, takes about 5 hours. In aluminum parts, etching is carried out with nitric acid, drilling a hole for its filling inward. The catalyst will be pieces of finely chopped steel wire. The spent acid is periodically removed with a pipette. The whole process takes 5-6 hours.

Drilling

You can remove the steel tap that has broken off inside the part with a drill. It will be possible to remove it in this way if the brittle alloy can withstand the load. For work, you need a screw carbide drill and a tool that supports a rotation speed of 1500-3000 rpm.

It is not necessary to cool the work plane.

The procedure for work will be as follows.

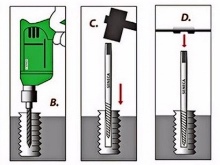

- Preparation... Use a round carbide tipped hairpin to grind the core area in the tap. It will look like a semicircle ledge. If the site is not prepared in advance, the drill can easily slip off.

- Securing the workpiece on a machine or in a vice on a rigid support. It is important that chips and other waste are easy to clean up during operation.

- Drilling... A securely fixed part will not move. It is necessary to set the drill tip exactly in the area of the core, start the rotation.

- Hole cleaning... The remnants of the tap can be removed from the part with any sharp instrument.

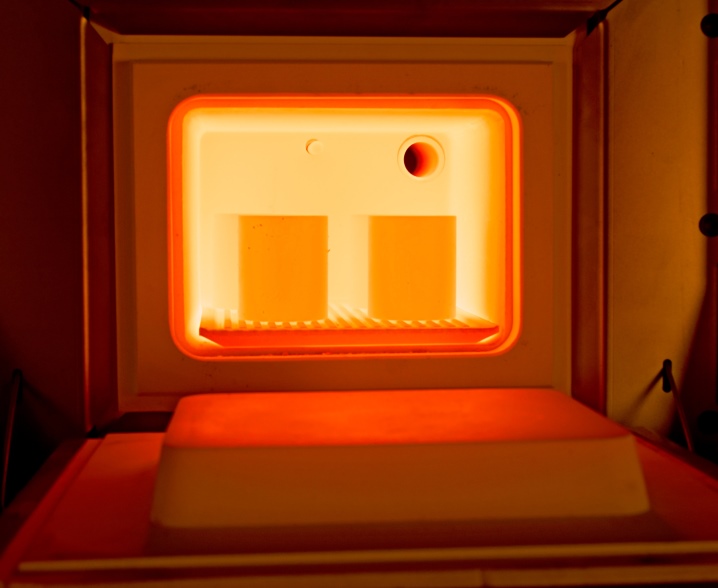

Upon completion of the work, it remains only to blow through the threaded holes from the remaining debris. When drilling, it is important to consider the type of steel. It is recommended to place high speed metal in a heated muffle furnace and then allow it to cool down along with the heat source.Carbon steel will have to be heated first and then slowly cooled.

other methods

Unscrewing a broken tap from a blind hole is usually much more difficult than from a through hole, but there are ways to solve this problem as well. Popular methods for turning out a firmly seated tool shank include the following.

- Welding... A new square-tipped shank must be attached to the tap fragment. When the joint has cooled, it will be possible to unscrew the stuck element with an ordinary wrench with a head of the appropriate type and diameter. If the tool breaks flush with the part, you can forgively weld the handle to it.

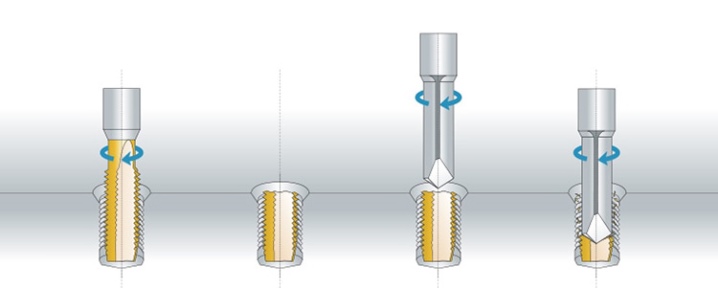

- Twisting... It will be successful if you use a combination of a special 4-lug mandrel or a countersink and a wrench. The first tool is attached to the tap, mating with its grooves. Then the knob is installed, with the help of which the rotation is carried out.

- Pulling out... It is made by means of a rigid wire that matches the diameter of the tap grooves. It will be enough to thread the double ends of an improvised instrument into these holes, and then make a little physical effort.

- Twisting... If the debris sticks out over the part, you can grab it with the jaws of a vise or pliers, and then unscrew it.

- Breaking... A small fragment can be removed simply by breaking it with a punch or a center punch made of hardened steel. The beaten off pieces will only have to be removed.

Heavy-duty tap rotation can be alleviated by adding a little kerosene to the tap grooves. This will make it easy to remove the stuck item.

The comment was sent successfully.