Features and types of taps

The tap is a cutter for cutting threads inside a hole. They are made in the form of a carbide screw, in which the thread is cut using an external helical groove that cuts the same in the holes of workpieces made of ordinary steel and non-ferrous alloys.

What it is?

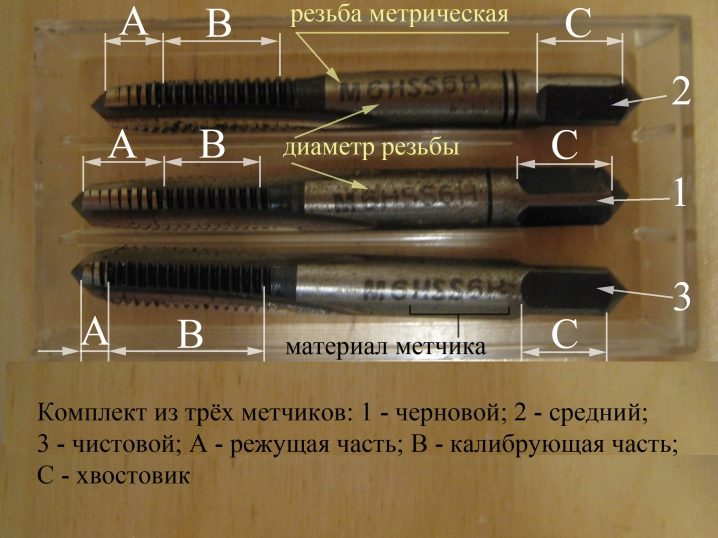

The shank tap is attached to a hand-rotated driver. In machine tools, the role of a wrench is played by a chuck driven into rotation by a drive. This allows you to increase threading tenfold, while serving not one, but several workpieces at once. The working area of the tool has cutting and adjusting parts. The profile of the helical groove on the tap exactly repeats the parameters of the groove being cut.

To cut a thread in carbide and hardwood parts, especially hard composite, three tools are used, each of which is designed for rough, semi-finishing or finishing work. The difference between these three tools is in the accuracy class of the helical groove. The more tough the alloy, the more taps are used: excessive toughness and elasticity create additional friction, leading to more noticeable overheating of the tool. Cutting, for example, steel 3 is limited mainly to the use of no more than two cutters.

Tapping in blind and through holes varies considerably in design. According to the area of application, there are also cutters for drilling machines and for manual threading. The mechanized one differs from the hand cutter by the outlines of the lead-in zone.

Machine taps fix in the same way as a drill - they do not have a shank shape designed for a wrench.

Views

To cut threads by plastic deformation, cutters are used that do not generate chips during operation. Their main feature is the absence of a channel for the removal of chips. Nut torches are used to cut grooves in nuts. They are distinguished by an elongated shank and the same lead-in part. Using a fine cutter instead of a rough cutter is also not allowed.

By appointment

Hand torches are used to form threads on parts used in small batch production. The shank is fastened to the wrench using a square mount. The roughing, semi-finishing, and finishing torches are numbered 1, 2, and 3, respectively.

Machine-manual are a hybrid, they are used on milling and drilling machines for a small workshop. They are distinguished by a shortened lead-in part, so that the tool will not break under noticeably heavy loads.

Nut cutters have a special structure, which is why the nuts do not screw off them, but go towards the long shank. When there are enough nuts, and they fill the entire area free from the cutting edge of the product, when removed, they easily slide off the opposite side and fold into a container receiving parts. Automatic machines force craftsmen to use cutters with bent shanks: the process does not have to be stopped in order to remove the nuts from the tap. The nuts, ready for transportation, slide off the shank on their own and rush into the receiving container.Fishing taps, which mostly have a large diameter, are used as cutters with which it is possible to extract pipes immersed in a channel drilled in rocks, which do not need to be used as a channel for pumping oil products. The fishing tap has an acute-angled thread and a hole ajar at the top.

The main requirement for fishing taps is resistance to overloads, which are unattainable when threading in domestic conditions.

By design

The range of taps for tapping is very extensive. Each of the tools is designed for a specific purpose. So, not containing grooves, taps are used for machining aluminum parts, as well as for workpieces made of alloyed aluminum. Chess-oriented ones have alternating cutting edges that reduce tool abrasion when machining parts made of extra-ductile alloys. Stepped cutters use a two-zone structure, one of which cuts a groove, the other removes chips, while the groove is re-ground. Stackable cutters combine a tap and a drill or broach. Channel cutters allow you to easily introduce lubricant in order to reduce friction tenfold and some cool the tool.

Bells work with holes of 5-40 cm, while the number of cutting edges reaches 16 levels in diameter.

By the type of thread to be cut

Metric and inch threads are not always completely compatible in diameter. Metric threads are cut in accordance with GOST 3266. Inch thread per inch corresponds to 25.4 mm. The inch thread differs by taking into account the number of groove turns for each such inch. Tubular cylindrical tools are marked as subclass G, after this designation is indicated the number of millimeters (or fractions of an inch, whole inches) in diameter, with a thread pitch in the number of threads per inch of hole depth. Tapered tubulars are signed as R-taps that cut a groove with a taper of 1/16, and the groove is cut until the end of the working part rests against the obstacle of the blind hole.

The thread differs in the left and right directions of screwing bolts and nuts. Like the bolt, the tap is twisted clockwise to the right and counterclockwise to the left.

Unscrewing, respectively, occurs in mutually opposite directions.

Materials (edit)

Threaded cutters are made of high speed steel, sometimes with diamond grit. Pure victorious taps work in stainless steel and titanium, as well as other carbide grades of steel. Steel grades for the manufacture of taps - U10A, U12A, P6M5, P18 and tungsten-containing alloys, or compositions with the addition of cobalt.

Dimensions (edit)

On the basis of the existing state standards - and there are several of them - the sizes M7 and M9 were absent in the USSR, since in mass production, single-digit odd denominations were used only in small values. Today, in the Russian, Belarusian and Ukrainian markets of all kinds of cutters, taps with a nominal value of M6, M8, M4, M10, M7, M3, M5, M2, M9, M10x1, M16, M12, M6x1, M20 are common.

Marking indicating the thread pitch is signed with two values - the first corresponds to the hole diameter of the workpieces.

|

Threaded groove, mm |

Drill, mm |

||

|

Diameter of the thread to be cut |

Step |

Millimeter thread |

Inch analog |

|

3 |

0,5 |

2,5 |

not set |

|

4 |

0,7 |

3,3 |

|

|

5 |

0,8 |

4,2 |

|

|

6 |

1 |

5 |

|

|

7 |

6 |

15/64 |

|

|

8 |

1,25 |

6,8 |

17/64 |

|

1 |

7 |

||

|

10 |

1,5 |

8,5 |

|

|

1,25 |

8,8 |

11/32 |

|

|

1 |

9 |

||

|

12 |

1,75 |

10,3 |

|

|

1,5 |

10,5 |

27/64 |

|

|

14 |

2 |

12 |

|

|

1,5 |

12,5 |

1/2 |

|

|

16 |

2 |

14 |

35/64 |

|

1,5 |

14,5 |

||

They are produced by Sibrtech, ZUBR, Interskol and other brands, whose homeland is Russia. By the way, Sibrtech has transferred a number of its production areas to China, which allows this company to use Chinese analogues of the Russian alloy P6M5 or U11A, therefore, home craftsmen approach the quality of Chinese products with particular scrupulousness: counterfeiting is possible - replacing a high-quality high-speed alloy with a softer substitute ...

How to use it correctly?

The use of a hand tap is as follows.

-

Prepare the workpiece by drilling one or more holes in it according to your project. Round off any sharp edges, remove burrs and gouges from roughing the product.

-

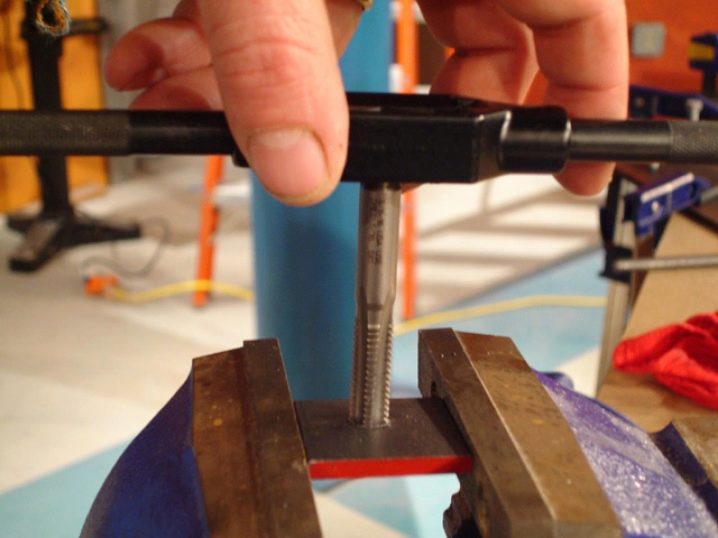

Place the part in the clamp, for example. in a vice, or secure with a bracket or clamp.

-

Apply industrial oil, lithol or grease to the working part of the tap and to the inner surface of the hole.

-

Orient the tap strictly perpendicular to the plane of the part. The perpendicularity should not be violated on either side when the holes were drilled in the same way, without beveling on either side.

-

Place the wrench on the hand tap and start rotating the cutter by screwing it into the hole. The main pace is as follows: half a turn or one turn forward, in the course of the future screwing of a screw or bolt - and the same amount back. The back passage of the cutter is necessary so that the tap, which leaves behind it, removes it in a timely manner.

-

After passing a few turns, do not forget to add oil or apply heavy grease. The oil-lubricating base helps to remove the formed chips from the newly cut groove in a timely manner.

If you do not continue to lubricate regularly, then the friction between movement and rest stops the cutter more and more, it goes tighter, the effort increases, part of the tap's working area may break off. As a result, the tap will have to be shortened - and then its use will be strictly limited in terms of the immersion depth. But more often the tap simply breaks and must be replaced with a new tool.

Automated machines that use a special cutter generally use the same operating procedure as for manual threading of a screw groove. The action plan for mechanized threading is as follows.

-

Prepare the parts for threading the mounting holes as in the previous instructions.

-

Mount the cutter in the chuck / collet of the drilling machine.

-

Apply grease or oil to the torch and the hole being machined.

Important: do not start the machine immediately at high speeds.

Engage in the lowest gear. It is even better to use a ballast that does not give out 220 volts (if the machine is powered by the mains voltage), but much lower voltages, for example, from 55 V. power cord in a safe place.

The fact is that a tap is not a drill: that, in turn, completely cuts off excess material according to a given diameter, displacing it with itself when screwing into the workpiece to be processed, which cannot be said about a tap cutter. He, unlike a drill, uses a slightly smaller original hole diameter for its advance: the thread in the latter must be tightly fitted to the bolt or screw - so that it is securely screwed into the part, and does not dangle along its outer threaded groove, without encountering any holding (running) force. Working with a tap at reduced speeds is explained by the simplest laws of physics (mechanics), which cannot be bypassed without damage to the workpieces and the cutting tool used. In other words, turning on high rpm, you will damage either the motor and the gearbox if the drive is low-powered, or you will break the tap when it is too small.

The comment was sent successfully.