All about hand taps

Taps are used to cut internal threads. These parts can be of various types. Today we will talk about the main features of hand taps.

Design features

These parts are slotted screws. They can be either straight or helical. The grooves form the cutting edges. The device of taps necessarily includes the following constituent elements.

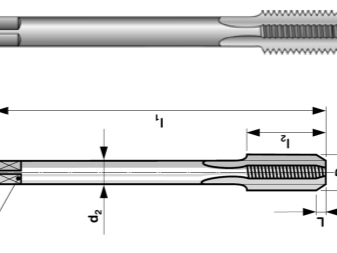

- Head department... It is called in another way the intake part. Its shape is similar to a gentle cone. This section is intended for making a threaded profile.

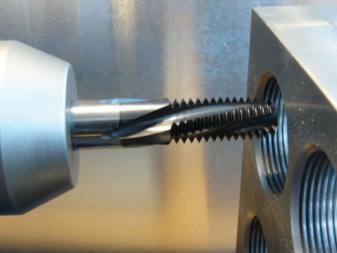

- Side grooves. The number may vary. They allow the swarf to be evacuated while the job is being done. Also, these parts provide the supply of special lubricant. These components can be of different types. So, there are straightforward departments that are used in a universal tool. There are also spiral left: they are intended to create a thread for the passage. The resulting particles are led away in front of the tap, protecting the profile from possible damage. There are also spiral right-hand parts, which are used to make threads in blind holes. Moreover, the chips will be pushed out and not clog the holes.

- Calibrating part. It has the shape of an elongated cylinder. The sizing element allows you to complete the correct shaping of the profile.

- Shank... This section is necessary to securely fix the product in the clamping device. The shank can be reinforced. This allows you to significantly increase the rigidity of the tool, and hence the durability.

Hand taps are almost indispensable when performing a variety of plumbing work at home and at work. On the shank of these devices there is a special milled square, a knob is fixed in it.

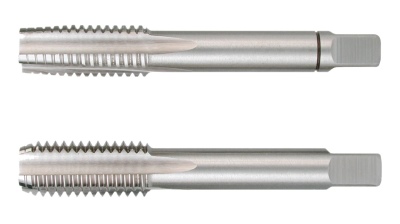

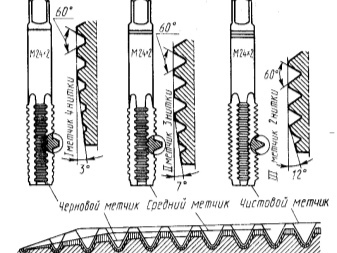

Complete copies include individual parts in the amount of three pieces: roughing, intermediate and finishing, all of them are appropriately marked. Sometimes there are also sets of two instruments.

The rough tap has a longer intake section and a reduced size for the average diameter of the threaded part. It is marked with # 1. The rest of the devices have a reduced length of the intake cone, which makes it possible to efficiently process blind holes as close as possible to their bottom.

It should be noted that hand taps most often allow the formation of metric threads. Also, these fixtures can form inch and pipe threaded portions. Such a tool can be two-pass or three-pass.

Such locksmith products can be made from various materials:

- high carbon steels;

- high-speed steel;

- hard alloys;

Dimensions (edit)

All dimensional values can be found in GOST 3266-81. Most often, models are produced with the sizes M10, M5, M12x1.75, M6. The numbers indicate the diameter of the tools in millimeters.

Application

Hand taps are used, as a rule, when carrying out household plumbing work. Most often, several such tools are used to form a thread. Each of them removes only a certain part of the material from the product.

If you need to carry out basic plumbing work, where the diameter can vary from 8 to 18 millimeters, then you can use a single hand tool. To make threads from 6 and 24 mm, a set of two devices is taken.To form a threaded part with a diameter of 2 to 52 mm, you will need a set of three such hand-made products.

The comment was sent successfully.