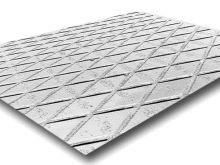

Features of corrugated rhombic sheets

Rhombic corrugated sheet is not just an indicator of the delicacy and aesthetic preferences of the owner of the object, but a severe necessity for a number of auxiliary areas in which it is used. It is used with no less success than the so-called chevary.

general description

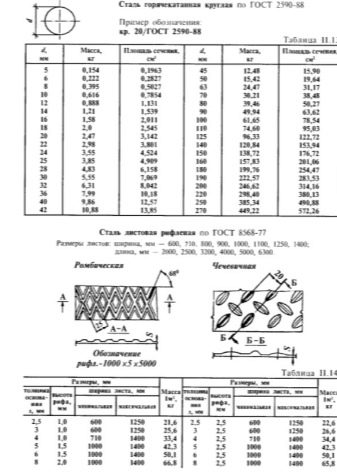

Application of a rhombic pattern to the sheet is one-sided. The GOST 8568-1977 regulation indicates that the following steel grades are used for the production of rhombic sheets: BSTO, BST1, BST2 and BSTZ, St1-St3, also prescribed by Gosstandart 380-2005. Russian analogues of American stainless steel AISI-321/201/304/316/409/430 are allowed as a starting material.

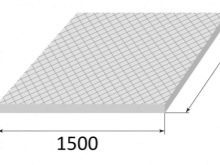

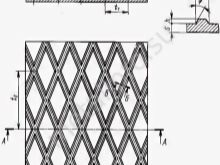

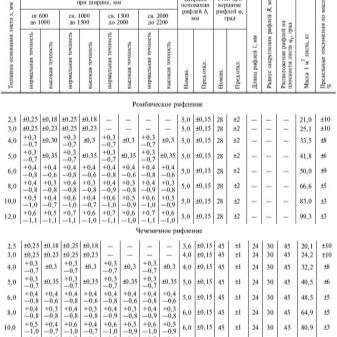

Corrugated sheet is made in widths of 60-220 cm. Length - 14 ... 80 dm, thickness - 2.5 ... 12 mm. Produced in sheet and rolled products. The height of the picture is 0.5 mm, the distance between the diamonds is 2 ... 3.5 cm. The size and distance between the diamonds vary several times. The geometry of the rhombic texture is correct, symmetrical. The diagonals of each rhombus are 25x60 mm, variable, according to the tolerance, up to 30x70 mm. The smaller and larger size of the diamond has not found practical use.

The height of the rhombuses on the sheet is not less than the bulging of half a millimeter above the main surface of the workpiece, normally 10 ... 30% of the thickness of the main part of the sheet. So, with a sheet thickness of 0.5 mm, the height of the rhombuses (their volumetric thickness, bulge) is at least 1 mm.

After rolling the blanks, the sheet is controlled in length and width in accordance with the errors specified in GOST, and is cut to the specified dimensions. However, rolling on continuous machines is allowed with rolled longitudinal edges. There should not be any dents, curvatures and accidental boring, however, small dirt and scale, prints are not considered a defect.

The original sheet, in which the repeating diamond pattern is made, is hot rolled. Unlike ideally smooth rolls intended for the usual rolling of ingots (slabs) into a simple sheet (even on both sides), the rolls of textured professional rolling themselves contain the same copy of the pattern - in a concave projection. The passage of the profiled concavities imprints the profiled convexities corresponding to the size and step of repetition, which are formed on the hot and slightly softened steel "pancake". That, in turn, is gradually formed from the soft slab.

Views

The classification of a rhombic sheet is made according to the range of steels: corrugated coil - and the same, but sheet. Along with the rhomboid, there is also a lentil corrugation, but not everyone is comfortable. According to the accuracy class, sheets with a surface rhombic profile are subdivided into "A" - special accuracy, and "B" - normal.

Along the width of the products, the sheets are 60.6 ... 220 cm. The profiling step (the gap between the rhombuses) is up to 25 mm. The length is from 1.4 to 8 m. The thickness of the sheet is from 2 to 8 mm. Typical values are 3, 5, 6, 7 mm, fractional - for example, in increments of 6.5 mm.

With tenths of a millimeter in thickness, rhombic sheets are made to a limited extent and under a special order, and do not go on mass sale.

Thin workpieces are made from stainless steel or from subsequently painted rusting "calm" steel. "Calm" steel, in contrast to semi-calm and "boiling", is devoid of nanopores caused by deoxidation of a certain degree, which means that even when covered with rust it will last much longer than its more deoxidized counterparts.

The maximum deviation in thickness does not exceed 200 µm. It is very difficult to ensure absolute - reference - accuracy, but GOSTs prescribe that the manufacturer (metal rolling) should get as close as possible to the ideal (calculated) value.

Finally, when calculating shipping costs, weight is critical. Even when the distribution company announced a promotional, free delivery of goods, its transportation to a specific object was initially included in the cost of the batch.

To calculate the weight of the latter, calculated and practical (real) values are used that have a tolerance for the possible deviation of the mass of 1 m2 of products. The most popular nominal value of the workpiece with customers is 6x1500x6000, 3x1250x2500 and several others - between these limits. The weight of sheets with a thickness of 2.5 to 12 mm is 20.1 ... 96.8 kg, according to GOST 8568-1077.

Applications

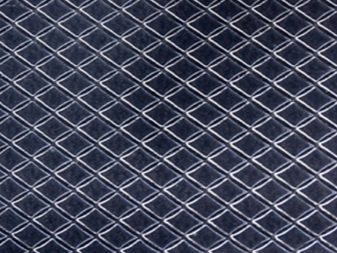

The sheet of rhombic "embossing" is in demand when arranging non-slip floors, for example, in ambulances, as well as in the cab of trucks and cars of any purpose. In buildings and crossings, it is used as a floor material for visitors and pedestrians, respectively. Especially the non-slip flooring will be appreciated by the elderly, for whom it is important not to fall in order to avoid injury; rhombic flooring is used for floors and stair treads.

Wall cladding and ceiling cladding are already used as decoration - the "diamonds" indicate the refined taste of the property owner. Fences used for safety reasons also provide for the use of such a covering, it can often be seen as the outer cladding of the walls of buildings (made of stainless steel). Such material has been produced for a long time - since the approval of the Soviet GOST-8568-1977.

The use of a corrugated sheet format blank with a rhombus is justified when producing parts of mechanisms - for example, for vehicles, conveyor lines for food processing. But metal sheets can also be produced as aluminum - the cases of many mechanisms, in particular, protective walls and casings do not require steel sheathing. An example is sawing machines, in which, in addition to a visor, an external skin is used, which covers the moving mechanics from accidental hit of the worker's clothes and other objects in the area of rotating gears and shafts. The thickness of aluminum rhombic sheets is at least 4 mm.

The comment was sent successfully.