All about sheets of PVL 306

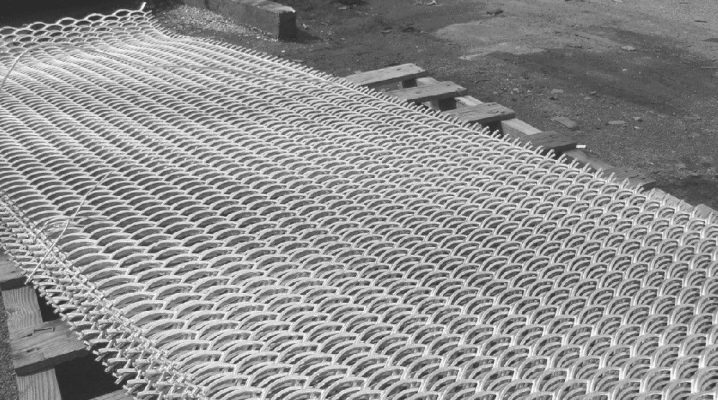

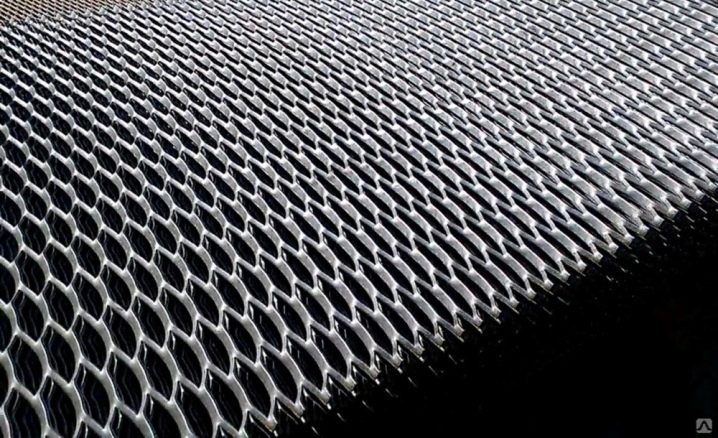

PVL sheets are produced mainly in the form of a grid with evenly spaced cells of the same size. The configuration of the leaf is a homogeneous structure. This sheet is used in industrial and civil construction, mechanical engineering and a number of other industries.

Peculiarities

The main feature of PVL 306 sheets is their low weight, which is in harmony with relatively high rigidity and elasticity. For the manufacture of these sheets, rust-resistant steel alloys and non-ferrous metals are used, which practically does not deteriorate in a fresh water environment and vapors.

The most widespread is the material made of steel grade not worse than St3. The degree of porosity does not matter - it can be calm, and semi-calm, and boiling steel. The dimensions of PVL 306 are inscribed in GOST 8706-1978.

The production of expanded metal mesh includes the following stages.

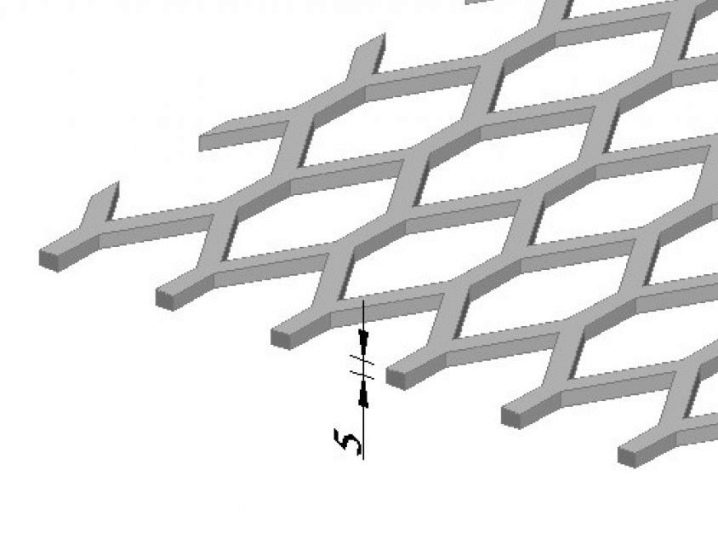

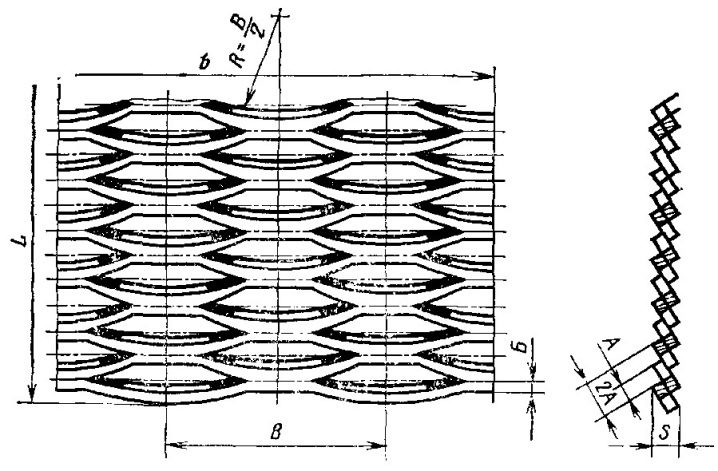

- All-steel billet undergoes a trick with the help of cutting knife stands-shafts of notches in its thickness. The location of the future cells corresponds to the principle "through a row, through one". According to the State Standard, the cuts have a structure that resembles rhombuses or scales on the body of a fish. When making cuts, the sheet is pulled out until these short slits acquire the size and structure in accordance with the diamond-shaped and scale-like texture.

- Then the sheet material is rolled along the elongated axes of the cuts, which gives it a flatter texture, which gives it additional resistance to deformation effects.

Technologically, the production process is called - drawing with simultaneous perforation.

Dimensions and weight

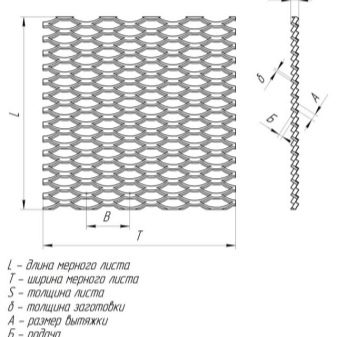

According to GOST and technical specifications, sheet-rolling of PVL 306 has the following characteristics:

- sheet 3x1000x2500 - sheet rolling used in many main and auxiliary industries;

- sheet 1000x2000 mm - a reduced version used in the installation and finishing of structures, which do not require particularly large dimensions.

Expanded steel sheets are also characterized by good workability: they are cut, welded and bent without any special restrictions. The weight of a 3x1000x2500 sheet is 30.5 kg, the thickness of the original sheet in which the notches are cut is 3 mm. According to GOST 8706-1978, alloy grade - St3PS5.

For expanded metal products, the thickness of rolled products is usually 3 ... 6 m. The length of the sheet blank is from 2 to 3.5 m.The width of the blanks fully prepared for purchase and installation is 0.5, 0.6, 0.7, 0.8, 1.0, 1.25 m.

The feed parameter for processing on a solid blank of cells for PVL 306 is 6 m. The cell pitch is 90 mm. The thickness of the cellular structure in the prepared form is 12 mm. Weight of 1 m2 - 12.9 kg, pulling distance in one pass - 12.5 mm. TU standards - 0971-001-44028369-2006, 3626-11589 and 27.1-25484714-1.

Applications

Due to its insignificant linear / square meter weight, anti-slip, self-cleaning properties, this product successfully replaces solid sheet rolling. In addition to significant - by their standards and parameters of similar materials - sheet metal PVL 306 withstands a significant temperature drop. Due to the ability to transmit air and light, the sheet is used when arranging translucent ceilings, fences and ventilation mines. Finally, due to a decrease in metal consumption by up to 5 times, the price of this rolled product is significantly reduced.

PVL is well suited for the construction of flights of stairs, reinforcement of reinforced concrete (instead of reinforcement). Ladders made with its use are independently cleared of snow when people pass along the steps. Precipitation and melt water flow off the structure rather freely.The hollow structure, from which the steps are made (no concrete), prevents people from slipping when passing on such a staircase.

PVL 306 is well suited for organizing decks and walkways, ramps for strollers and bicycles, motorcycles. Storm runoff sites in closed areas also contain PVL - as well as TV towers, radio masts and cell towers for servicing high-rise electrical and radio equipment. The list of PVL applications threatens to become endless.

Corrosion-proof expanded metal sheet imposes the only storage limitation - the absence of acid vapors. Tsvetmet also does not allow the presence of alkalis, some salts. But rusting steel, in addition, is afraid of dampness and moisture.

During transportation, PVL is tied with a wire with a step of 1 ... 1.5 m between the screed lines, packed in blocks weighing 1 ton each, between which spacers are placed at least 20 cm wide and at least 2 m thick.

If all of the above conditions are not met, then the products will deteriorate significantly before they finally reach the facility under construction.

The comment was sent successfully.