Varieties of galvanized sheets and their use

Knowing the types of galvanized sheets and how to use them is required for everyone who decides to finish the roof. It is necessary to take into account the specifics of painted galvanizing and other steel sheets for the roof in rolls. You also need to familiarize yourself with the nuances of painting galvanized metal sheets and products of demanded companies.

Features of production

Technologies for protecting metal from corrosive activity have been given special attention for many decades ago. Since then, the number of metal structures used has only increased - and these methods have improved. Often there is a galvanized steel sheet that can withstand the effects of an aggressive environment. Rather thin steel specimens can be taken as a basis. The protective coating is applied in different cases, both on one and on both sides.

Galvanizing can be done not only with simple zinc, but also with an iron-zinc composition. For subsequent use in construction and repair, the method of cold galvanizing is mainly used. The rolling itself is preliminarily obtained in a hot state.

Coatings that are very resistant to cracks and chips are formed on it.

Rolled steel always has a predetermined thickness, which is determined by the requirements for a specific object. To avoid the formation of dross, the surface should be acid etched. Hot-dip galvanizing is carried out mainly by galvanic methods. Semi-calm steel grades are usually released on galvanized sheets. The galvanic technique allows you to achieve the fastest possible application of the material.

However, the layer will not be mechanically strong enough. It will not work to get a thick protective shell by electroplating. But it will be possible to achieve outstanding decorative properties. Thermal diffusion technique achieves exceptional stability of the insulating layer. True, the level of costs and energy consumption of such a method severely limit its application.

Main properties and characteristics

The parameters of galvanized metal sheets are quite good, and such products can guarantee a long service life. The strength and flexibility of zinc-clad metal is quite high. It is not difficult to bend and bend such structures. Welding, drilling and other machining techniques are carried out without any problems.

The mass of galvanized sheet is relatively small. This greatly facilitates its transportation and storage, as well as moving around work sites. The metal under the zinc layer is not subject to the damaging effects of moisture and ultraviolet radiation. The aesthetic parameters of the products are very high.

Most often, the high strength of the models is also noted.

Galvanized sheet thickness varies according to standard. Typical thicknesses (including coating):

-

0.3 mm;

-

0.5 mm;

-

0.55 mm;

-

0.6 mm;

-

0.7 mm;

-

0.8 mm;

-

1 mm;

-

1.2 mm;

-

2.5 mm;

-

3 mm.

Views

Galvanized sheets in rolls are in demand. Usually these are long products with a thickness of up to 2 mm. The coating is usually applied on 2 sides. The advantages of this solution are:

-

versatility of machining;

-

resistance to corrosion;

-

resistance to deformation load;

-

long period of use.

The color of zinc coated sheet can be quite different.The white material (RAL 9003) is popular. But in the standard there are at least several hundred color options, which allows you to choose the best option for yourself. Often a roll sheet has:

-

corn yellow;

-

pale yellow;

-

sunny yellow;

-

transport orange;

-

wine red;

-

fiery red;

-

pink;

-

burgundy purple color.

Along with this, non-ferrous hot-dip galvanized steel sheets can also be coated with:

-

blue-lilac;

-

sapphire blue;

-

ocean blue;

-

grassy green;

-

black and green;

-

olive gray;

-

pearlescent pink;

-

brown-gray coating.

The base coat itself is applied hot or cold. The second option involves processing workpieces strictly at room temperature. The greatest thickness of the protective layer will be 20 microns. The cold zinc coating is only intended for use in non-aggressive environments. Electrolysis plays a key role in the processing.

Hot-dip galvanizing is carried out in special baths. It guarantees much better protection against corrosion and rust stains. The metal itself is preliminarily warmed up to 450 degrees before immersion. The result can only be influenced by varying the temperature. Therefore, the "hot" method is capricious, despite the fact that it is very expensive.

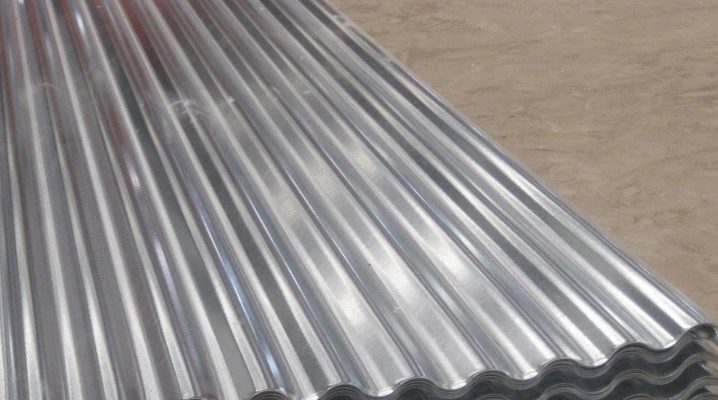

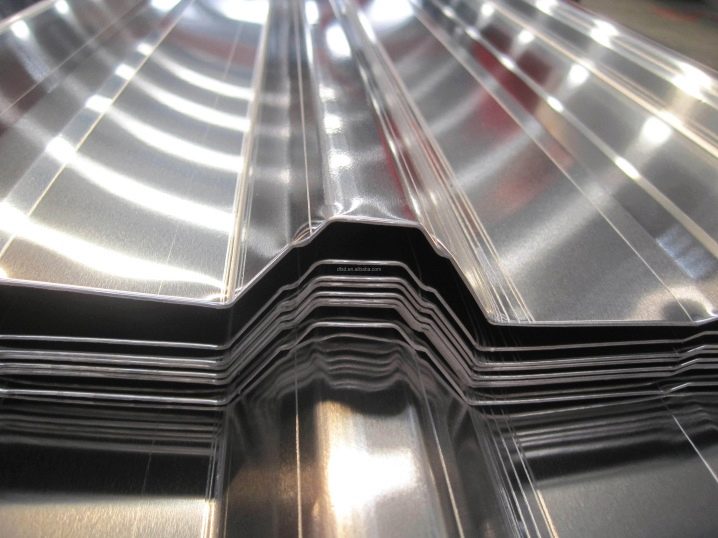

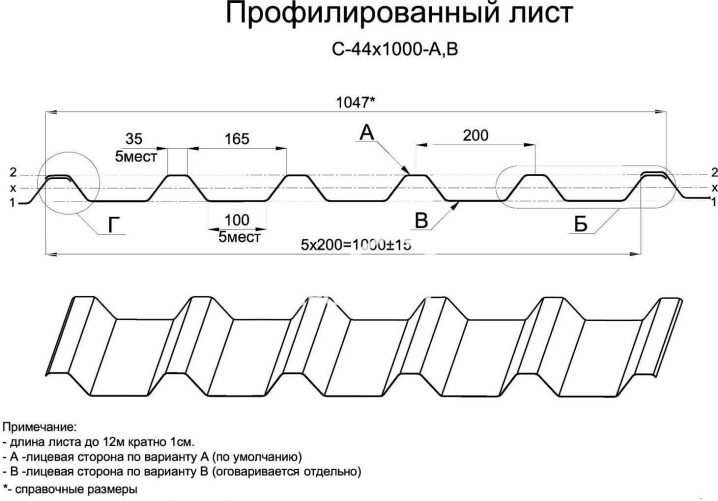

The front surface is not always completely smooth. Often it has a wavy appearance, and this solution is actively used in roofing. Visually, this material is somewhat similar to slate.

The usable width varies widely. The thickness of the sheets usually ranges from 0.35 to 0.8 mm.

Wave sheets can last a very long time and do not require complex maintenance. Moving them around is pretty easy. Stacked corrugated sheets take up little space. Colors vary widely. It is not difficult to mount and dismantle such material, if necessary, it is perfectly used in a repeated cycle, and due to the rigidity of the sheets, they can be placed on a sparse crate.

There are also different coverage classes. It is customary to mark the higher class with the letter P. In this case, from 0.57 to 0.855 kg of zinc per 1 sq. m. The thickness will range from 40 to 60 microns. In this case, the resistance to corrosion processes will be the highest.

Galvanizing in class 1 implies a double-sided layer of zinc 0.258-0.57 kg per 1 m2. The coating will then be no thinner than 18 and no thicker than 40 microns. The worst option is class 2. It assumes that a layer per "square" will weigh from 0.142 to 0.258 kg. As a result, the thickness will vary from 10 to 18 microns - which, of course, directly affects the overall reliability of the coating.

Popular manufacturers

A quite decent galvanized sheet is being made in Russia. Products are a good example of this. Petersburg firm "Kayumars"... It is affordable and meets the needs of most customers. Deliveries are made in both wholesale and retail modes. The manufacturer "Kayumars" has been present on the domestic market since 2000 and has already gained solid experience.

Severstal is also a major supplier of galvanized steel. The goods are shipped in both traditional sheet and roll formats. The assortment includes products of the 2nd zinc-plating class. The weight of a single pallet can be up to 3500 kg. Additional strapping is performed as needed.

NLMK (that is, Novolipetsk Metallurgical Plant) is an excellent competitor for the two already named firms. In rolls, this company ships over 100 types of galvanized metal. Typical width is 125 cm. The manufacturer promises to promptly ship any volumes. Thickness varies from 0.025 to 0.3 cm.

PJSC "MMK" also supplies first-class protected rental. Its total thickness varies from 0.05 to 0.49 cm. In Magnitogorsk, the protective layer is applied both by the hot method and by the electrolytic technique.An additional polymer coating can be applied. The Ural manufacturer sometimes uses metal of first-class hardness.

Application

Various products can be created on the basis of galvanized sheets. Without them, it is almost impossible to imagine the automotive industry and the production of other transport mechanisms. A material with zinc protection is in demand for roofs and other building structures, and it is also used in the manufacture of furniture. Additionally, it finds application:

-

in the manufacture of machine tools;

-

in precision instrumentation;

-

in the production of devices for the chemical industry;

-

in the creation of parts of various kinds.

Painting nuances

A factory painted sheet usually doesn't look too bad. However, even the best brand colors can gradually degrade. In addition, periodically the old tones cease to be liked or go out of fashion. It is sometimes necessary to paint galvanized metal after a while also because even the best protective layers gradually lose their quality. At home, you can paint protected metal with your own hands without any problems if you follow the basic requirements and nuances.

For work use:

-

acrylic dyes;

-

vinyl coloring mixtures;

-

formulations based on alkyd components;

-

rubber paints.

Acrylic paints are valued for their long life and weather resistance. They are inexpensive and adhere well to the material. Alkyd enamels are mainly used in areas with a maritime climate. They are useful due to their additional anti-corrosion effect. Another important nuance of alkyd enamels is a glossy sheen.

The surface of the metal will have to be prepared very carefully. An important role is played by the build-up of adhesion to the applied dyes. Quite often, it is necessary to carry out abrasive processing so that the coloring matter adheres more easily, penetrates into microcracks and micropores (if they are not enough by default). In any case, zinc is purified and treated with a solvent, even if it has been in contact with air for a long time.

The paint layer should be fairly thin; ideally, it is applied twice, waiting for the initial mass to dry completely.

Alkyd reagents are used to coat an exceptionally clean and dry surface. Polymer paints cannot be used at home, because high-quality polymerization takes place only in industrial production. The shade is selected taking into account the color scheme of the object. Pneumatic painting is highly productive, but only trained professionals can do it correctly. One cannot ignore the nuance that it creates a fog that requires the use of personal protective equipment.

The comment was sent successfully.