Smooth galvanized sheets

Smooth galvanized steel sheets are sheet products with a variety of applications. In the article we will consider their features, types, range of use.

Peculiarities

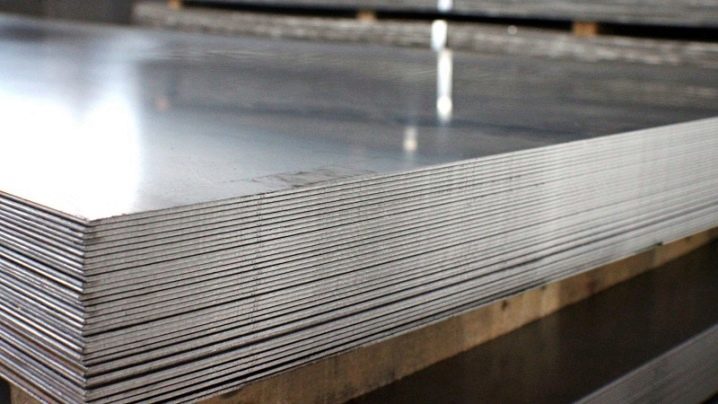

Smooth galvanized sheets are produced in accordance with GOST 14918-80. Their quality is checked at every stage of production. The work uses cold-rolled sheet steel. The parameters of the raw materials used are 75-180 cm in length and 200-250 cm in width. Galvanizing increases the resistance of the steel to corrosion and chemical attack. Treated flat sheets are durable and flexible. They can be given any shape. They can be sealed by welding. They are durable and last at least 20-25 years. The zinc coating is quite dense; building materials with different colors and markings are used for work. Thanks to this, they can be selected for a specific architectural plan or project.

The technological process can provide for the application of a zinc layer of various thicknesses to the steel surface. Its indicator depends on the purpose of the processed material. The minimum thickness is 0.02 mm. The production method is electroplated, cold, hot (with stage-by-stage coating). In electroplating, zinc is applied by electrolysis. The second method involves applying a tread compound like paint. In the latter case, the surface is degreased, etched, washed. Then the raw material is immersed in a zinc melt bath.

Processing time, coating quality, molten metal temperature are automatically controlled. The result is perfectly flat and smooth sheets with improved characteristics.

Specifications

Galvanized sheets allow for any type of further processing. They can be rolled, stamped, bent, pulled without fear of damage to the zinc coating. They are more practical than ferrous metal, do not need paintwork. They have an impressive assortment. Environmentally friendly, the coating is harmless in comparison with other analogues. They tend to heal themselves if they are accidentally scratched. They have a flawless matte finish.

Smooth zinc plating is resistant to vertical and horizontal loads. Thanks to this, it is used as a raw material for metal structures. It is easy to install and has a thickness of up to 1-3 mm. The thicker the sheet, the more expensive its price per 1m2. For example, rolled products with a thickness of 0.4 mm cost from 327 to 409 rubles. An analogue 1 mm thick has an average cost of 840-1050 rubles. The disadvantages of the material are considered a slight loss of thickness during operation and the need to prepare the base before painting.

Types and marking

Galvanized steel sheets are classified according to different criteria. According to their intended purpose, they are marked as follows:

- HP - cold profiling;

- PC - for further paint;

- Xsh - cold stamping;

- HE - general purpose.

In turn, sheets marked with XIII by the type of hood are divided into 3 types: H (normal), G (deep), VG (very deep). Sheets marked "C" - wall, "K" - roofing, "NS" - load-bearing. Wall sheets are especially flexible and flexible. Galvanized steel has a length in the range of 3-12 m and different weights. The carrier is versatile, with an optimal balance of rigidity, lightness, plasticity. Suitable for both walls and roofs. By type of thickness, building materials are divided into 2 types.Products marked with UR indicate a reduced type of thickness. Equivalents labeled HP are considered normal or typical.

Sheets vary in thickness of the covering layer. Based on this, their labeling can mean a different class:

- O - typical or ordinary (10-18 microns);

- V - high (18-40 microns);

- NS - premium (40-60 microns).

In addition, sheets are classified according to the type of coating and rolling accuracy. Variants with the abbreviation KP indicate a crystallization pattern. Analogs with the letters МТ do not have a picture.

The accuracy class is marked as follows:

- A - increased;

- B - typical;

- V - high.

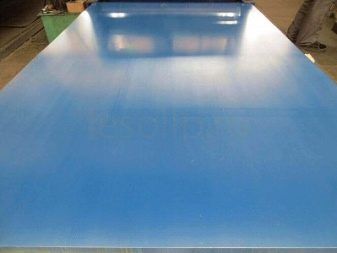

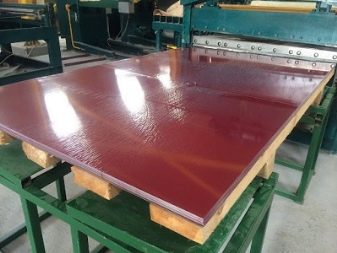

Standard dimensions of rolled products are 1250x2500, 1000x2000 mm. In addition to galvanizing, sheets can have an additional protective layer. The type of coverage varies. Painted steel sheet with polyester coating protects against moisture and wear. Its color is varied - in addition to white, it can be blue, orange, yellow, green, beige, brown, burgundy. The plastisol coating is resistant to mechanical stress. It is a plastic layer with a matte texture.

The pural polyurethane coating is considered to be especially strong and durable. In addition, the coating can be powder-coated, with a characteristic gloss. The color palette of galvanized sheet includes 180 shades. The coating itself can be either one-sided or double-sided. The edge of the sheets is edged and unedged.

Applications

Galvanized sheets are used in construction, economic activities, modern heavy and chemical industries... Their range of applications is diverse. Their elements are contained in all kinds of structures, for example, railway stations, ships and others. They are used in the automotive industry, various metal structures. From products with a thickness of up to 0.5 mm, folded roofs and facades are produced (end strips, corners, ridge). The material has found application in the production of drainage systems, headrests for supports, fences, fences, ventilation ducts. It is used to extinguish sauna pipes.

It is used for wall cladding of cabins, industrial buildings, truck vans. It is used in the manufacture of furniture fittings, as well as bearing guides. For outdoor use, sheets are used, made according to the hot-dip galvanized principle. Their surface is slightly dull. For internal work, analogs are used with an electroplated coating that has a gloss. Smooth galvanized sheets are used for formwork.

Painted is used in the production of metal tiles, facing siding, fences, sandwich panels.

The comment was sent successfully.