PLASTFOIL membrane

Providing waterproofing is one of many important construction and manufacturing steps. To carry out this process, special materials are used, which are called membranes. At the moment, among the many manufacturers, it is worth highlighting the PLASTFOIL company.

Peculiarities

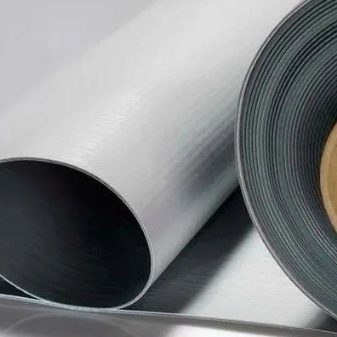

The main material for the manufacture of membranes from this manufacturer is polyvinyl chloride. Currently, it is he who is the basis for such products. But the company is trying to improve the technology of its processing and sets strict standards for itself, which subsequently make it possible to form serious quality control at its own enterprises. The reinforced construction makes the membranes durable and ready for harsh environments and physical damage. One of the most important characteristics can be called resistance to ultraviolet radiation, due to which the products can be placed in open spaces.

PVC membranes make it possible to construct roofing systems without the use of an open flame. In addition, in comparison with other materials, experts and ordinary users note the high installation speed, which is due to the installation in one layer. Reinforced PVC is revolutionary in that it is both strong and lightweight due to its structure, even with a large coverage area. This simplifies both transportation and installation and subsequent operation. The physical properties of this material are very unique, so the membranes can be installed at low temperatures.

Naturally, technological values also require certain indicators of environmental friendliness. Therefore, the membrane produced is clean and not harmful to the environment. In addition, the raw material is in a low flammability group, which excludes its ignition in unforeseen situations.

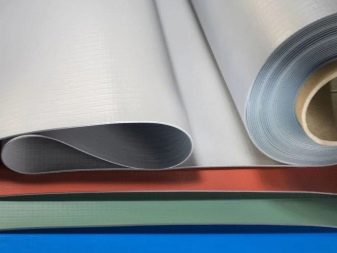

In terms of design, membrane products have succeeded here as well. At the moment, most of the products are made in different colors, which the consumer can choose when purchasing from a certain area.

Product range

PLASTFOIL CLASSIC - standard membrane, which is a structure with a reinforced mesh. Thanks to her, the product does not creep, prevents the appearance of various damages - cracks and tears. The main advantages include increased chemical resistance, wide weldability window, flexibility at low temperatures, as well as impact and puncture resistance. Thickness in several variations - 1.2 / 1.5 / 1.8 and 2 mm. The width is constant and is 2.1 m, the length is from 15 to 25 m.

PLASTFOIL FL - a model made by extrusion and calendering of special PVC. The key difference of this membrane from any others is its extremely low flammability, therefore FL is used for waterproofing buildings and premises with special fire safety requirements. A strong mesh improves the basic physical characteristics of the product, and the smooth surface of the membrane promotes uniform heating of the weld areas, which affects the formation of a single web. Typical size one is 1.2 mm thick, 2.1 m wide and 25 m long.

PLASTFOIL ECO - a universal model with good characteristics. The main advantage is the high degree of environmental friendliness of the material, which has been the result of many developments. The typical size is the same as for the CLASSIC. Among other physical characteristics, there are all those that are inherent in most membranes of this manufacturer.ECO can be called a simple and reliable option for those who do not want to overpay and who do not need product specialization.

PLASTFOIL POLAR - one of the specialized models prepared for operation in the coldest environments, where the temperature can reach -55 degrees. Improved PVC manufacturing formula makes installation more convenient. Reinforced structure to withstand heavy loads. The POLAR membrane is resistant to ozone and various oxidations. PVC is very flexible at low temperatures, and the smooth surface with a single sheet contributes to a wide weldability window.

Where is it used?

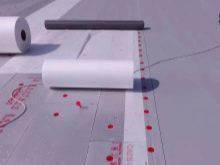

The scope of application of PVC membranes is quite diverse. To a greater extent, it consists in waterproofing flat roofs with different fixation variations. Many of the models can be used in traditional ballast, unexploited roofs. The CLASSIC product will be an excellent option for arranging the roof on a cement-sand or prefabricated screed. Some membranes are adapted for use in non-continuous ballast systems.

Quite often, such products are used in the roof of residential buildings, exhibition and warehouse premises, as well as shopping malls and large stores.

The comment was sent successfully.