Reverse osmosis membrane

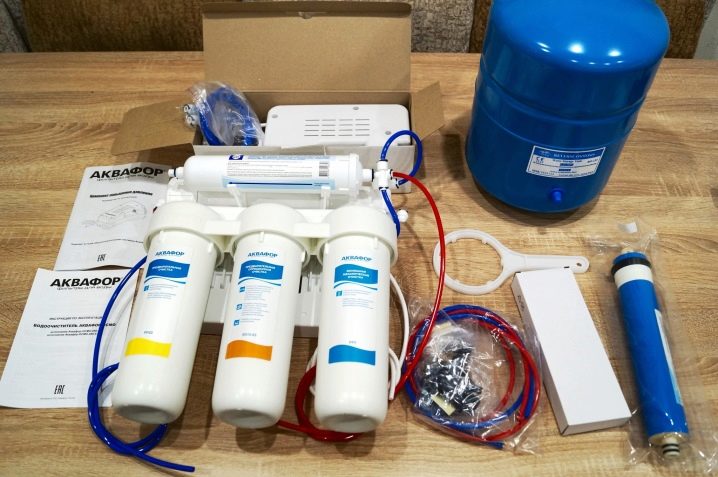

Modern filtration systems that operate on the basis of the reverse osmosis principle are in great demand. They guarantee almost crystal clear water, regardless of the original quality and condition. However, certain parts of such equipment, including the reverse osmosis membrane, require periodic diagnostics, maintenance and replacement.

What it is?

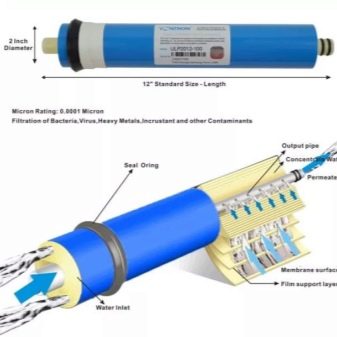

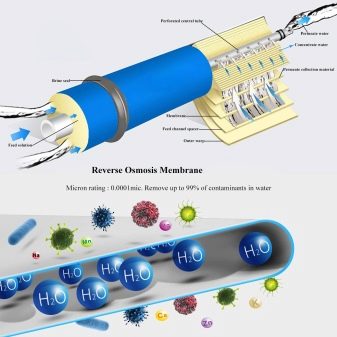

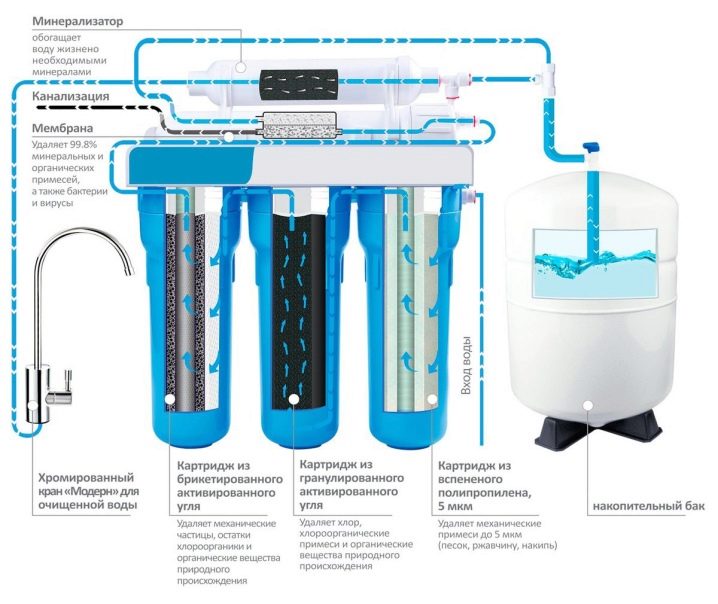

The reverse osmosis membrane is a key element of the filtration system. It consists of cells, and the main characteristics are determined, as a rule, by the size of the pores. Only water molecules are passed through these cells. Thus, it is effectively purified from contaminants of various origins, as well as from viruses. The important point is that the membrane converts a highly concentrated solution into a less concentrated solution. As a result of such filtration, the water gets rid of salts, organics, bacteria, that is, it is completely purified.

It is important to note that there are industrial and domestic installations that are designed differently and have certain maintenance features. Typically, household models are easier to use, but may not require filter cleaning. In such situations, with heavy contamination, the part will need to be replaced. But it is also worth considering that the membrane is the most expensive component of the entire reverse osmosis system, while it is characterized by increased sensitivity to the primary quality of the liquid. This explains the need for pre-cleaning.

A key characteristic of a membrane element is its service life. It is determined by the operation of the pre-filters, as well as the initial state of the water. The service life is 2-4 years. It is important to bear in mind here that the purchase of the most expensive installation does not always guarantee a maximum 4 years of operation.

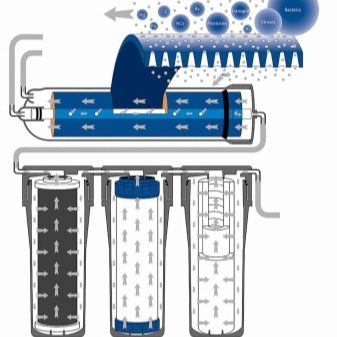

Principle of operation

Analyzing the features of the functioning of reverse osmosis plants and what the membrane serves for, it is important to note that in this case the quality of water purification depends on electrical conductivity. All impurities in a liquid have a certain electrical charge. This is also true for the membrane element itself. Due to these properties, the separated particles are actively repelled from each other. If they begin to pass through the filter element, then in such situations, restoration (regeneration) of the membrane is required.

When the system is operating, water in a large volume passes through the membrane unit and is purified. It is important to take into account that the most aggressive (primarily chemical) contamination has an extremely negative effect on the performance of the described filter elements, accelerating their wear. To pass through the filters, an appropriate pressure is required, which is reduced by contamination. That is why the key to effective operation of cleaning equipment is the timely replacement of cartridges.

Otherwise, you may encounter a number of problems, namely:

- poor quality water will pass through the main filter;

- the membrane unit will be constantly overloaded;

- the performance of the element will be actively reduced;

- the quality of the outlet water will deteriorate.

It is necessary to remember the importance, from the point of view of the performance of the entire system and the membrane unit, in particular, mineralizers and post-filter. The odorlessness and taste of drinking water depend on post-processing.

Flushing methods

At the moment, two methods are used for washing membrane filters of devices for water purification by the considered method: mechanical and chemical. It is worth paying special attention to the effectiveness of these two technologies. In the second case, we will talk about the correct choice of a chemical agent and compliance with the instructions for its use. But, regardless of the flushing method used, it is important at the preliminary stage to determine the type of source of the problem, that is, the type of pollution itself.

Taking into account the composition, the following options can be distinguished.

- Organic. We are talking about plankton, microorganisms, as well as biodegradation products and more.

- Synthetic polymers (reagents), which are used in water purification.

- Anionic polymers. These substances are added to plumbing systems in order to prevent the formation of sediment (primarily referring to iron and a number of other metals).

- Petroleum products.

- Colloidal type compounds.

- Silt and other organic matter.

- Minerals, the list of which, among other things, includes phosphates and carbonates of a number of substances.

Mechanical

This method is based on the change in pressure in the system. Due to the pressure in the opposite direction, all debris is pushed out by water and plaque is removed. When it comes to industrial systems, the membrane filters are washed in this way up to 5 times per hour. Moreover, the duration of each cycle is about 30 seconds. It is important to take into account that the result of mechanical cleaning is directly determined by the speed of the generated flow.

Chemical

There is a fairly wide range of products used to clean industrial filtration plants. If we are talking about flushing the reverse osmosis membrane, which clogged at home, then citric acid can be used quite successfully. This approach allows you to effectively and quickly get rid of colloidal substances and inorganic deposits of varying complexity. To reduce the acidity of the agent used, the addition of ammonium hydrochloride is recommended.

The second popular option is to flush the membrane using hydrochloric acid. This is an acidic solution that acts quite aggressively. In this case, the field of application here is similar to the situation with citric acid. To remove biological contaminants, including films, fungi and mold, it is necessary to wash the described element with an alkaline solution, which contains dodecyl sulfate and sodium hydroxide.

As practice shows, most often it is required to clean membranes, including ultrafiltration membranes, from biological contaminants. The fact is that they are capable of spreading throughout the entire contour in record time. It is also important to take into account that, as a rule, several different deposits are formed on the membrane element. Taking into account all the features, cleaning is most often carried out in two stages using acid and alkaline preparations.

How to check if it works?

The predictable concentration of salts and various impurities in the treated water directly determines the service life of the filter elements. It is also important to consider that one of the key indicators of a membrane is performance. It turns out that the main symptom of any malfunctions is a noticeable decrease in the volume of fluid passed through the installation. An equally important point is that the pressure in the water supply system itself should be taken into account. It is desirable that this indicator starts from 2.8 atm. The easiest way to check the condition and performance of the membrane is by passing water directly through the filter unit.

This will require:

- shut off the water supply from the system to the tank;

- open the tap that is responsible for the supply of drinking water;

- let the water from the system go directly to the filters.

These actions allow you to visually assess the flow of treated water. In this case, it is important that it is continuous and uniform. Any deviations from the norm will indicate the presence of contaminants in the system. But do not forget about possible drops or low pressure indicators in the water supply system itself.

How to replace and install?

The membrane, which is a film with cells, is enclosed in a special plastic case, which, in turn, is part of the reverse osmosis filtering system. Within the framework of the work under consideration to restore the equipment operability, it will be necessary to change only the film itself. In most cases, such a process does not require special skills and significant time costs.

The algorithm itself will include the following steps.

- With the help of a ball valve, the water supply from the water supply system is completely shut off. At the same time, it is important to close the filter unit and the storage tank.

- Certain operations are performed with the so-called post-filter. We are talking about the disconnection of all pipes and the subsequent dismantling of the specified element of the system together with the fasteners.

- Disconnection of the plastic block, inside which the membrane itself is located. It will be necessary to separate each tube as carefully as possible, after which the body of the membrane unit is removed from the fasteners.

- Opening the housing and removing the membrane itself. By and large, it can be thrown away immediately.

- Place a new element in the housing by screwing it in.

- Consecutive installation of the entire structure by performing the above steps in reverse order. It is important here to connect the pipes correctly according to the connection diagram. Install alternately a plastic membrane unit and a post-filter.

- Checking the performance of the filtering installation with a stable water flow.

It is important to take a break (approximately 5 minutes) before completing the last step. This need is due to the fact that all excess air must leave the system. Only then is it recommended to open the tap to check the water supply.

How to choose?

First of all, it should be noted that in the overwhelming majority of cases, the described elements of filter systems from the same manufacturer are interchangeable. At the same time, when choosing this component of the reverse osmosis structure, it is important to consider:

- daily water consumption and system performance;

- pressure in the water supply;

- properties of the treated water;

- the presence of a drainage flow restrictor;

- equipping the filter with a boost pump.

In addition to all of the above, it is important to remember that there are different types of reverse osmosis membranes. At the same time, at the moment, spiral elements are in the greatest demand. These are two diaphragms positioned appropriately around the branch pipe.

For information on how to flush a reverse osmosis membrane, see the next video.

The comment was sent successfully.