Weight of expanded clay concrete blocks

Expanded clay block is a building material that replaces concrete, standard (clay, silicate) brick due to its decent heat and sound insulation properties. It is suitable for walls, foundations and underneath wood floors.... The article will consider such an indicator as the weight of expanded clay concrete blocks.

What does weight depend on?

Like any building block, expanded clay concrete has parameters on which its specific weight depends.

-

Dimensions (edit)... The length and width of the solid or porous material from which the expanded clay concrete block is made is one of the decisive factors.

-

Dimensions and number of voids... Hollow blocks, which help to better save heat in a building or a building constructed from them, may contain from one to several voids of the same size. The more voids, the less their own weight indicators. The location and number of voids is determined by the shape - most often the voids are located inside in the form of rectangles or slots communicating with each other.

-

Porosity... Expanded clay - foamed fired clay, before firing, filled with gas-forming (pore-forming) reagents. The smaller the granularity of the pores, the more of them - and, accordingly, the lighter the expanded clay brick.

-

Proportions in the construction mixture, which is expanded clay concrete. Clay, sand and cement, added to the mass from which the bricks themselves are made with the help of molds, are mixed in certain proportions. The more cement, the better the clay is processed, the more durable expanded clay bricks and blocks from it will be made by the master. But this does not mean that it is necessary to replace with cement most of the dry construction mixture used for the production of expanded clay concrete blocks - this would lead to an increase in the cost of each such brick (and the entire batch as a whole), and would also contribute to their premature cracking.

Having data on the used construction mixture, residual moisture (hardened building material does not lose the rest of the water), air content in pores and voids, it is realistic to determine how much one block weighs.

How much do the different blocks weigh?

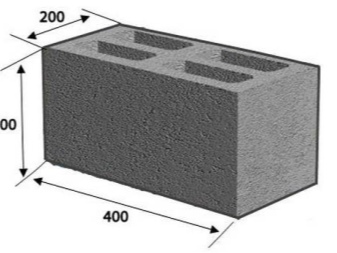

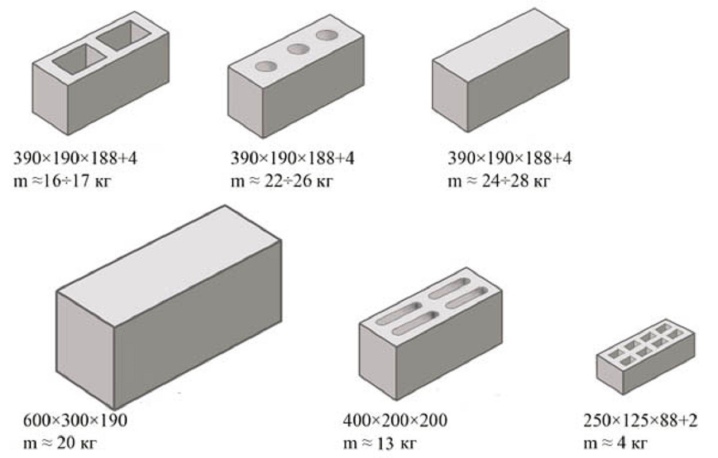

The most popular in our country is the expanded clay block with dimensions of 40x20x20 (20x20x40) centimeters (in millimeters - 400x200x200, 200x200x400). It is used for the construction of load-bearing walls of low-rise and one-story buildings. It also showed itself well as a partial substitute for the classic concrete M400 / M500 as part of the foundation. These dimensions are indicated taking into account the corrections for cementing glue joints (or for ordinary cement-sand mortar): the actual dimensions are 390x188x190 mm (390x190x188, practically the same size). Experts like the dimension of 390x190x190 mm more, as it contains two repeating numbers. The number of voids varies from 2 to 7. Two voids have rectangular and circular outlines - in longitudinal section when the block is viewed from above and below. Three are round or square, four are rectangular; blocks with 5-8 voids can contain gaps of different shapes (except for non-standard ones). Block weight - from 10 to 15 kg / piece. High quality - strength and hardness - the hollow block is lost when the total weight is reduced below 10 kg.

Detailed information on the characteristics of the varieties of expanded clay bricks are given below.

|

Structure |

Strength marking |

Specific weight, kg |

Density of material, structure kg / m3 |

Heat conductivity, W / m per degree |

Frost resistance |

|

With voids |

M-35 |

11 |

750 |

0,24 |

F-25 |

|

M-50 |

12 |

850 |

0,28 |

F-35 |

|

|

M-75 |

14 |

1000 |

0,35 |

||

|

M-100 |

16 |

1100 |

0,39 |

F-50 |

|

|

No voids |

M-75 |

18 |

1300 |

0,54 |

F-35 |

|

M-100 |

19 |

1400 |

0,57 |

Having decided on the compliance of the selected expanded clay block with the declared requirements, the buyer will submit the order to the delivery company (or directly to the manufacturer). The firm, having accepted the application, will calculate the mass of a batch of expanded clay concrete requested by this user. In particular, the weight of one pallet with blocks is determined. A wooden pallet weighs up to 80 kg - it must withstand the specific gravity of all bricks stacked on it. Accordingly, one "cube" of blocks contains 31-32 pieces. The mass of a cubic meter of hollow claydite blocks is from 496 ... 512 to 620 ... 640 kg - adjusted for the rounded dimensions of expanded clay concrete bricks in 40x20x20 cm. With a euro pallet, this value increases to about 600 ... 750 kg.

It is for this weight that a truck is selected that is capable of transporting a multiple number of such pallets with expanded clay blocks. A truck crane (or a forklift truck), in turn, must have a double (or more reserve) in terms of carrying capacity - 1.5 tons or more.

The fact is that each pallet with blocks will be lifted and moved to a height of up to several meters after the ordered cargo arrives at the construction site.

How to check the quality by weight?

There are no gaps in hollow blocks - except for the small pores that penetrate the entire thickness (or fragments entirely consisting of expanded clay) of such a brick. Hollow blocks weight - 16 ... 20 kg / piece., in some places and a little more. The quality - in terms of strength, the value of the permissible load - is considered by weight, but it is useful to check the batch of blocks for compliance with GOST in composition: 50% expanded clay, 30% washed river sand, 10% water and 10% Portland cement.

Chasing lightness, the builder significantly loses in the reliability of the building being erected. For example, a solid block is used for the foundation, bearing walls and "gate" wall (or pillar) supports. Hollow - mainly as wall partitions (curtain walls). For the purpose of additional thermal insulation, an additional layer is used - due to the thickening of the walls from the outside with the help of highly porous and high-void expanded clay bricks. The consumer decides for himself what is closer to him - greater strength and mass or greater heat and sound insulation, coupled with less weight.

High-quality expanded clay concrete has a permissible load of 50 ... 150 atmospheres... For comparison, it would have to withstand the pressure on the surface of Venus (92 atm) without cracking. After the expiry of the warranty period, the permissible load on the expanded clay block is reduced by 1/10. Thermal conductivity in accordance with GOST and industry, technical standards should not exceed 55 milliwatts per square meter when cooling air "overboard" per degree Celsius. Expanded clay blocks do not give any shrinkage - the constructed structure or wall will not sag even by a millimeter, without taking into account the properties of the cementing joints. The density of expanded clay concrete without voids should not exceed 1500 kg / m3.

If expanded clay in a block is replaced by crushed stone screenings, crushed rocks and brick chips (or small brick / glass breakage), then such a block weighs much more - due to the use of materials of increased density in it.

Then these are already simple concrete bricks that have nothing to do with expanded clay. A conscientious seller, at the buyer's request, will cut one block from a batch (a pallet with such bricks) - the user will see with his own eyes that there is the required amount of expanded clay in them. To demand an inflated price for a brick block, in fact, made from waste not provided for by the recipe, the manufacturer - and with it the supplier - has no right. If such violations are found, it is recommended to change the seller of building materials.

The comment was sent successfully.