All about the weight of gas silicate blocks

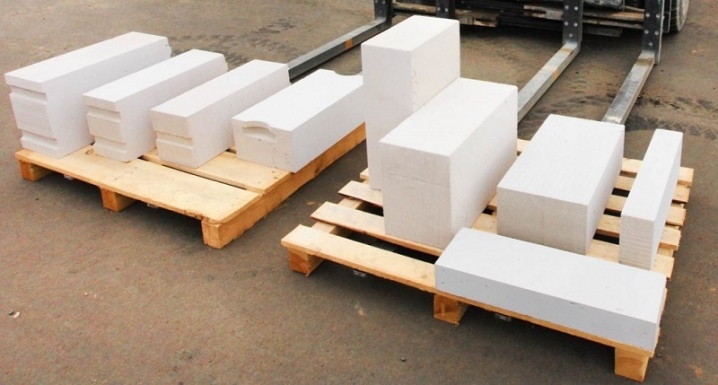

Gas silicate blocks are often used in construction. They come in 600X300X200 and 200X300X600, 600X200X300 and 600X300X250, 600X400X250 and other sizes. You should know the weight of one block of gas silicate and a cube of this gas silicate, as well as a list of significant factors.

How much do the different blocks weigh?

Gas silicate block structures are widely used in construction, reconstruction and renovation of buildings. Although this material successfully competes with brick and traditional concrete in terms of density, the mass of products made from it is very relevant. Knowing the weight properties is useful:

- when calculating foundations;

- when determining the characteristics of floors;

- when preparing for storage of blocks in warehouses and directly at construction sites;

- for the correct planning of transportation, selection of the right transport and packaging.

In some cases, there is a gas silicate block 600X300X100. It finds application due to its increased thermal and sound insulation qualities. When using the 500th grade of concrete, the bearing characteristics will be sufficient for low-rise and high-rise construction. The mass of one block will be 15 kg.

Therefore, lifting it yourself will not be difficult.

With a value of 250X300X600, the weight of one building element will be 36 kg. It is theoretically possible to lift such a product with your own hands. But it will be more accurate and more accurate to lay it with an assistant. The descriptions indicate the significant bearing capacity of the material. It can be used as a thermal barrier.

The block 300 by 200 has considerable popularity, or, more fully, 600X300X200, in other versions 200X300X600 or 600X200X300. Its density belongs to grades 500-700. It is these products that are used in construction work. Weaker brands are needed only for insulation work.

100X250X600 (aka 600X250X100) is also a common building material. A standard cargo pallet holds 120 of these blocks. There are 6.67 items per 1 m2. The mass of 1 structure is 10.5 kg, so it is quite simple to use it.

Another demanded solution is 600X400X250, or otherwise 250X400X600. This is a great option for low-rise buildings and for an indoor partition divider. Comparative lightness is achieved due to the cellular structure. The usual frost resistance is 100 cycles, that is, the material can be guaranteed to be used for 30-40 years. Weight norm - 14.4 kg.

Parts of 600X300X250 can also be made of gas silicate. This is a good wall material with a unit weight of 22.5 kg. Compression strength category from B2.5 to B3.5. There are 22.2 units per 1 m3. The main purpose is capital construction.

Weight 1 pc. gas silicate 625X300X250 is equal to 28 kg 130 g. Wall panels of this type are produced with a density of D500. Among others, they are also produced at the Kostroma plant. The main production standards are set in GOST 2007.

Cold resistance level - F35.

Gas block 625X300X200 is quite acceptable for single-layer masonry. It is unacceptable to use smaller blocks for this purpose. Gross indicator - 30 kg. Designs are suitable:

- for houses;

- in suburban construction;

- in garage construction.

Silicate 600X400X200 is non-toxic. Its frost resistance is sometimes F75. This is typical for the "Thermocube" products. Weight - 30 kg. Compressive strength - B3.5.

In the line of silicate building parts Ytong stands out block 625X400X250. In its production, they are guided by GOST 31360, adopted in 2007.One block pulls 43 kg 800 g. Traditionally, the density of the material is D500, the frost resistance of the product is equal to F100. And this is how the table of the specific gravity by mass of gas silicate blocks looks like (with the D500 brand).

|

Dimension, mm |

Estimated dry weight, kg |

|

600X300X100 |

15 |

|

250X300X600 |

36 |

|

600X300X200 |

21 |

|

100X250X600 |

10,5 |

|

600Х400Х250 |

14.4 (average) |

|

600X300X250 |

22,5 |

|

625X300X250 |

28,13 |

|

600X400X200 |

30 |

|

625Х400Х250 |

43,8 |

But not everything is as simple as it seems. Builders and repairmen are not always guided only by the weight of 1 unit of products. Sometimes for them the weight of the gas silicate cube is much more important. The fact is that it is on the volume that they are guided when they deal with storage and transportation. The capacity of warehouses, individual storage positions, trucks and wagons is measured in cubic meters.

To calculate what the mass of 1 m3 will be, you must first determine how many blocks fall into this value. Let the indicators of gas silicate elements 25X40X62.5 cm be analyzed. Multiplying all these parameters successively, we will see that the result is 0.0625 m 3. It is not difficult now to estimate that there should be 16 blocks per 1 m3. Further calculation, if you know how much 1 copy weighs, is not difficult.

If you take a pack of gas silicate measuring 62.5X25X20 cm, then it usually contains 64 pieces of such products. But the volume of the container is 2 m3, and this circumstance is very important for the correct calculation during transportation. Calculating the actual weight of the pack is not difficult. You just need to pay attention to the volumetric weight of the finished product.

And you don't even need to recognize it - it is already included in the brand name after the letter D.

Influencing factors

The weight of gas silicate blocks is a variable value that depends not only on the dimensions of the product, as is often (and erroneously) thought. First of all, the density of the hard part of the product is of great importance. The moisture content of the gas silicate will also have to be taken into account. The density level is indicated in the labeling of the supplied goods. It is usually measured in kg per m 3.

Density marks are designated as DXXX, where XXX is the desired value. There is nothing complicated here, the specific weight of mass-produced units can be 300 or 400 kg. For denser products, this figure reaches 500 or even 600 kg. The influence of moisture is also predictable - the more water the sample takes in, the heavier it becomes, and the porosity of the building blocks only increases the severity of this process.

Moisture saturation is associated with the peculiarities of the production technology. Aerated concrete produced in autoclaves inevitably absorbs water. After all, it is always kept in saturated steam, and even at significant pressure. Therefore, at the time of packaging and shipment to the manufacturer, the silicate block contains at least 25% water, and sometimes this figure reaches 30%. Accordingly, the selling weight is just as much higher than that declared by the manufacturer.

Subject to proper installation and sensible operation, the humidity will decrease to about 5% in a few years.

Calculation features

The definition of mass is based on the size of the structure and its specific gravity. Let there be a gas silicate block 60X30X20 cm in size. And let the density correspond to the D400 brand. The technique is as follows:

- all sides of the block are multiplied (it is advisable to take them in millimeter terms);

- get the millimeter volume of the structure;

- this indicator is converted into cubic meters (in this case, 0.036 m3 is obtained);

- multiply the resulting number by the weight index of the brand and get a total weight of 14.4 kg.

But there is another subtlety that is often overlooked. Basically, the calculation of the gravity of silicate assemblies is needed to determine the load on the foundation. In this case, humidity can be neglected, since during normal use it will still return to normal quite quickly. This will happen by the time the roof is arranged, window and door openings are installed. However, it must be remembered that at first the gas silicate is still quite heavy, and you will have to build a house or other structure together with assistants.

The calculation cannot ignore water saturation when it comes to storage or shipping. Sometimes, because of this, even very unpleasant incidents appear. For example, if a dry building element pulls 21 kg, this does not mean that such properties will always be preserved. With solid moisture, the weight can easily increase up to 23 kg. Therefore, you have to work extremely carefully and carefully.

It must be remembered that the lighter the material is initially, the more it "drinks" from the atmosphere, and the more significant the weight gain is.

The comment was sent successfully.