How many gas silicate blocks are in a cube?

The gas block is a popular building material with which you can erect durable buildings up to 16 m high. Every day gas silicate blocks are becoming more and more popular, manufacturers regularly update and improve the range.

Before starting construction, it is important not only to decide on the material of the future structure, but also to correctly calculate the required volume. It is worth taking a closer look at how to determine the required number of blocks.

Calculation formula

The best way to count the material is worth considering with an example. Suppose it is planned to build a box 8 by 8 meters and a height of 3 meters. The house will have 4 windows with openings of 1.5 by 1.5 meters, as well as a doorway with dimensions of 2.1x1 meters.

Let's analyze the stages of counting.

-

First of all you need to calculate the volume of the wall, for the construction of which gas silicate will be used. To do this, you need to multiply the height of the box and the sum of the height and length of the building: (8 + 8) x3 = 48 m3. At this stage, window and door openings are not taken into account.

-

Second step - calculation of the volume occupied by the openings of windows and doors: 1.5x1.5x3 + 2.1x1 = 8.75 m3.

-

Stage Three - calculation of the final volume. To do this, subtract the result obtained at the second stage from the initial number: 48-8.75 = 39.3 m3.

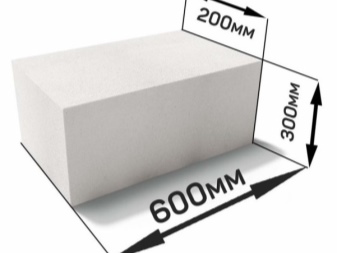

At the end, it remains to divide the resulting volume by the dimensions of the block used. Thus, it becomes clear how to determine the required number of gas blocks. For example, if a gas block of 600x300x200 mm will be used for the masonry of the house, then you will need to order: 39.3 / (0.6x0.3x0.2) = 1092 pieces.

This calculation method is considered simple and affordable. In addition, it is suitable for counting stones of all sizes, if maximum accuracy is not required. If you wish, you can calculate in advance how many blocks of a certain size will be in 1 m3, and then determine the total number.

You can determine the exact dimensions of aerated concrete products on the website of the manufacturer from whom you plan to place an order. Usually on such portals tables are published, which present the required values.

This will speed up the calculations and allow you to determine the exact amount of gas silicite both in one cubic meter and immediately in the required volume.

The number of pieces of gas silicate of different sizes

The gas silicate block is a material with excellent performance characteristics. The construction of residential buildings from such blocks will ensure comfortable living, because in the summer it will be cool inside the house, and in the winter it will be warm.

The structure of the gas silicate block contains up to 60% of small air bubbles, which increases the performance of sound insulation and helps to achieve the desired temperature regime in the building. This structure also made it possible to reduce the weight of the material.

There is a large selection of aerated concrete blocks on the building materials market. All products can be divided into two main groups:

-

rectangular blocks;

-

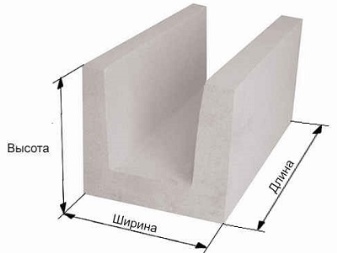

blocks in the shape of the letter U.

The latter option is used to arrange lintels over door and window openings.

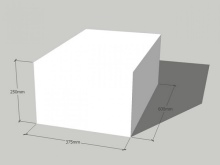

In hardware stores, you can find blocks of different sizes. Dimensions of standard products:

-

length - from 600 to 625 mm;

-

height - from 200 to 250 mm;

-

width - from 85 to 400 mm.

These are the most common options for gas blocks. If desired, the size of the product can be changed without much difficulty. This was achieved due to the low specific gravity and airy texture: the block is easily cut.

If we consider the dimensions of the U-shaped blocks, then the standards are:

-

length - from 500 to 600 mm;

-

height - up to 220 mm;

-

width - from 250 to 400 mm.

For the construction of one-story and two-story boxes, gas blocks with a minimum width of 200 mm are usually used.

In colder areas, thicker products are recommended.

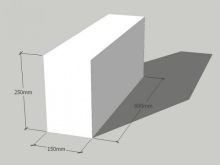

If we talk about the selection of blocks for laying internal walls, then products with a width of 85-100 mm are suitable here.

The main dimensions of gas blocks are presented in the table.

|

Dimensions of aerated concrete block, cm |

Total density, kg / m3 |

Weight of one product, kg |

Volume of one product, m3 |

Number of blocks in one pallet, pcs. |

The total volume of products in the pallet, m3 |

Total weight, m3 |

|

60x30x20 (length, width, height) |

500 |

19 |

0,036 |

33 |

1,152 |

570 |

|

60x30x20 |

600 |

22 |

690 |

|||

|

60x30x20 |

700 |

25 |

807 |

|||

|

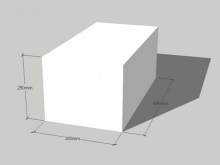

60x30x25 |

500 |

22 |

0,045 |

25 |

1,08 |

535 |

|

60x30x25 |

600 |

26 |

650 |

|||

|

60x30x25 |

700 |

31 |

760 |

Blocks are especially popular: 600x300x250 and 600x400x200 mm for the construction of the outer walls of the house. For partitions, blocks of 150x250x600 are often taken.

The estimated amount of aerated concrete for construction work depends not only on the weight and dimensions of the product, but also on the density. In any case, you first need to complete the project of the building planned for construction, where it will be indicated in detail what size blocks and what specific weight will be used.

Situations are quite common when blocks of different sizes are used to build a box. It will not be difficult to count the number of pieces of a gas silicate block of different thickness, width or height for the construction of a box if you approach the calculation correctly. To do this, you need to decide in advance which blocks will be used in construction, as well as what percentage of the box they will be. And you can also determine in advance how much volume the outer thick walls will have, and how much will be required for the construction of inner partitions of a smaller thickness.

Next, it remains to carry out a few simple calculations. First of all, you will need to calculate the total volume of the box, and then determine what volume is the specified percentage. The last stage is to determine the number of blocks of the required section using the scheme described above.

A few tips:

-

the calculation of the number of cubes of the future house should be made as close as possible to the results of the calculator;

-

in the store where the purchase will be carried out, it is worth clarifying the real dimensions of the gas silicate blocks;

-

when calculating the required number of gas silicate blocks, it is necessary to take into account the design data of the building structure;

-

during calculations, it is worthwhile to lay a stock of 10-20%, since scraps will appear during the construction process.

Careful calculations will help you buy the right amount of material and save money. When buying a gas silicate block, it is worth taking into account not only the parameters of future walls, but also the square meters of the room, which should remain unchanged.

The best option would be a preliminary layout of the building, which will take into account the dimensions of the premises and the thickness of the walls.

The comment was sent successfully.