Construction crushed stone: characteristics and types

Construction crushed stone is an important type of aggregate for concrete, asphalt, road and railroad embankments. Crushed stone, which has a beautiful appearance, is used as an element of artistic decoration of the landscape. Released in tons and in bags.

Specifications

Construction crushed stone is a universal material for construction, repair and arrangement of objects and territories for various purposes. Its main characteristics are frost resistance and strength. Frost resistance is a value equal to the number of long-term freezing and defrosting cycles.

It is known that when microcracks form on any stone, regardless of its size, water gets into them. Freezing, it is distributed in all directions; ice takes up one tenth more space than liquid water in its original state. The strongest stone will crack under the pressure of ice.

The number of freeze-thaw cycles will one day reach a critical value - the stone will be so riddled with cracks that it will turn into a stone crumb.

In terms of frost resistance, crushed stone differs within several brands of products.

- The high-resistance fractions include the brand of crushed stone F-200/300/400. This crushed stone is suitable for the construction of high-rise buildings, bridges, external dumping, piers in sea and river ports, as well as in northern latitudes.

- The F-50/100/150 brand is used in the middle lane and in the south of Russia.

- Volatile factions - F15 / 25/40. This rubble must not be loaded. It is only poured onto the paths and sidewalks, put into the drainage below the GWL. It is used mainly for internal work: for heated elements of buildings, as well as for treatment facilities.

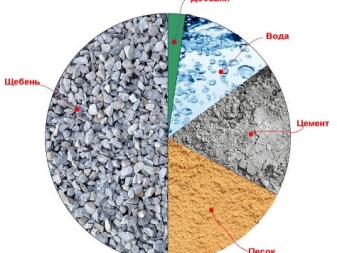

Measurements of the frost resistance parameter are carried out on the open fraction. Getting into concrete, crushed stone acquires additional frost resistance - on all sides the pebbles are surrounded by a cement-sand mortar, and this characteristic improves up to 40%. The strength of crushed stone is no less important than the resistance to frost, an indicator. In laboratories, the stone is subjected to crushing, accelerating its wear.

The values corresponding to certain grades of crushed stone - in terms of strength - are shown in the table.

|

Marking |

Strength group |

|

M-1600 ... M-1400 |

Extra durable |

|

M-1400 ... M-1200 |

High strength |

|

M-1200 ... M-800 |

Normal strength |

|

M-800 ... M-600 |

Reduced strength |

|

M-600 ... M-300 |

Weak strength |

|

M-200 and worse |

Particularly weak strength |

Strength marking is determined by the content of impurities that are not quite dense in consistency in accordance with the total weight of the crushed stone batch. The test portion is tested with a load equivalent to approximately 200 Earth atmospheres. Weak breeds are mixed in different percentages:

- M-1600 - less than 1%;

- M-1400 ... M-1000 - up to 5%;

- M-800 ... M-400 - up to 10%;

- M-300 ... M-200 - up to 15%.

Rock crushed with more than 1/5 of the weakened fraction by weight is called gravel. It is used for filling temporary and secondary roads, where asphalt and concrete are not required for use. Its second purpose is a rough floor in change houses, construction of temporary buildings, arrangement of utility sites and other not quite critical facilities.

In some cases, the gravel is thoroughly washed from dust, clay, sand residues and other inclusions that reduce, for example, the strength of the foundation.

Views

Crushed gravel is formed by the method of screening out quarry rocks during the destruction of rocks by directional explosions. Gravel is less durable than granite, has a grayish color scheme. The advantages of this building material are as follows.

- it is mined in many places, the firms that produce it are constantly in competition with each other;

- low cost - gravel crushed is widespread;

- simplified production process, low radioactivity.

In terms of fractions, the product is intended for the following types of work:

- up to 10 mm (screening) - used for filling roads and sidewalks;

- up to 20 mm - is used for the production of paving slabs;

- up to 40 mm - added to concrete for reinforced concrete products;

- 20–40 mm - into concrete for pouring the foundation.

Limestone crushed stone - calcium carbonate - a material compacted to a rocky consistency. It looks like gravel. White in color, looks attractive. Granite crushed stone is mined by directional explosions of dense rocks (natural stone). Further, the resulting rock is crushed and sieved. Has a reddish tint. The broken edges of each pebble adhere perfectly to the cement-sand filler. The shine of uncontaminated stones of such rubble gives an attractive appearance to the jellied floor. Compared to limestone and gravel, the material is unusually strong, the composition of crushed stone has stones up to 12 cm in size. The quality requirements are the highest.

Slag crushed stone is produced from waste of ferrous and non-ferrous metallurgy. Thanks to this, concrete products are significantly cheaper than products containing rock crushed. Secondary crushed stone - brick, stone, foam and gas-block breakage (processing of construction waste). Used concrete products can be used. Secondary crushed stone is half the price of granite.

Application in construction

The crushed stone fraction plays an important role.

- Up to 5 mm. The product is needed as a decorative covering in the garden or on sports fields. On the roads, this rubble is used for rainwater drainage.

- 0.5-2 cm. Goes into concrete with granite crushed. They are given secondary paths. Old asphalt is also used instead of rocks. Concrete with this fraction is used in airports.

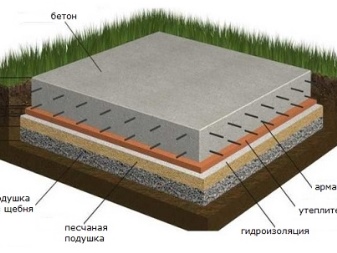

- 2-4 cm. They are poured a gravel cushion under highways, reinforced foundations of industrial buildings, railways.

- 2-7 cm. The material is used for the first layer for airfields, bridges and high-rise buildings.

- 7 cm or more. It is used as a decoration for swimming pools, ponds, alpine slides and other attributes of the landscape.

Also, by mixing different fractions of crushed stone, they achieve increased concrete strength.

The comment was sent successfully.