Fiberglass: features and scope

It often happens that the repair made does not please for long with an impeccable look. Painted or plastered surfaces are covered with a network of cracks, and the wallpaper begins to move away from the walls and become covered with “wrinkles”. Preliminary preparation of surfaces allows avoiding such problems - reinforcement (strengthening), leveling, application of a composition to improve adhesion - a rather large amount of work.

They can be replaced by gluing fiberglass based on fiberglass threads. It will strengthen the walls and ceiling, get rid of small cracks. The topcoat will lie flat, no defects will appear even if the walls of the building shrink.

The material is suitable for application in both residential and office, industrial premises. The main thing is to choose the right type of fiberglass.

Peculiarities

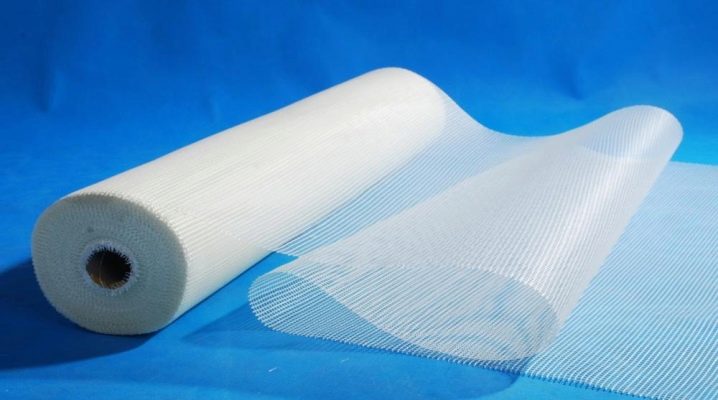

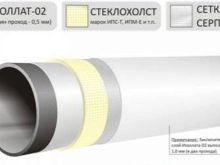

Fiberglass is used for rough finishing to prevent cracking of the finishing material, its deformation during the shrinkage process. The material is nonwoven sheets based on fiberglass filaments that are compressed. Material release form - rolls 1 m wide. Material length - 20 and 50 m.

GOST dictates different thicknesses of threads and their interweaving in a chaotic manner, which provides a reinforcing effect. The density of the material is 20-65 g / m2. Depending on the purpose of the material, rolls of one density or another are selected. Fiberglass with a density of 30 g / m2 is optimal for interior work.

Due to its low density, the material looks like a translucent canvas, for which it received another name - "cobweb". Another name is glass-fleece.

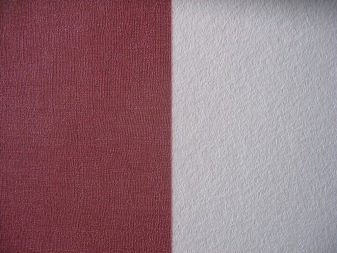

A feature of the material is the presence of the front and back sides in it. The front side is located on the inner side of the roll, it is smoother. The back is more fuzzy for better adhesion to the surface.

Fiberglass can be attached to any type of surface, including for putty, painting, decorative plaster. Preventing cracking of the finish, the material allows the walls to "breathe".

Advantages and disadvantages

The main advantage of the material is the ability to eliminate cracks and deformations in the finish. The fiberglass has good adhesion, which ensures its tight adhesion to different types of surfaces.

The material is hypoallergenic, since it is based on natural ingredients (quartz or silicate sand), so it can even be used in childcare facilities. Thanks to good vapor permeability, it is possible to obtain "breathable" surfaces.

Among other "pluses" are the following:

- good moisture resistance, so the material is suitable for use in rooms with high humidity (bathroom, kitchen);

- fire safety, since the material is not flammable;

- not affected by fungi, mold;

- non-hygroscopicity of the material, due to which the optimal microclimate is always maintained in the room;

- does not attract dust and dirt;

- high density, which provides the effect of reinforcement and slight leveling of surfaces;

- wide temperature range of use (-40 ... + 60C);

- the ability to use on different types of surfaces, apply for painting, putty, wallpaper;

- the ability to use on surfaces subject to increased vibration load;

- wide scope - in addition to strengthening surfaces, fiberglass, like fiberglass, can be used in roofing and waterproofing works;

- high elasticity and low weight, which simplifies the installation of fiberglass;

- light weight.

The disadvantage is the formation of the smallest particles of fiberglass, which appear during the cutting and installation of the blade. They can cause burns if they come into contact with the skin. This can be avoided by protecting the exposed areas of the skin, and the respiratory organs with a respirator.

Fiberglass is often called a type of fiberglass. However, such statements are erroneous. The materials differ in production technology: glass fiber wallpaper is made of fiberglass by weaving, and fiberglass - from fiberglass threads by pressing. This difference also determines a different scope of application of materials: glass fiber wallpaper is used for the finishing coat, while canvas is used to prepare the surface for further finishing.

Views

Painting fiberglass can have different densities. Based on this, there are 3 groups of "cobwebs":

Density 25 g / m2

The material is ideal for gluing to the ceiling for painting, therefore it is also called ceiling. The light weight of the canvas does not load the surface and absorbs less paint. It can be used on a relatively flat ceiling with small cracks.

Density 40 g / m2

A multipurpose fiberglass, the use of which is recommended on surfaces more damaged by cracks than the ceiling. The performance characteristics allow the use of glass mat of this density for walls, for ceilings finished with dilapidated plaster, as well as on surfaces with a high vibration load. The topcoat is also varied, plaster, paint, wallpaper, based on fiberglass or non-woven coatings.

Density 50 g / m2 or more

Technical features allow the material to be used in industrial premises, garages, as well as on surfaces subject to large destruction with deep cracks. This type of "cobweb" is the most durable, and its use is more costly. The costs are associated with the purchase of the material itself (the higher the density, the more expensive), as well as with the increased consumption of glue.

Manufacturers

Today in the construction market you can find glass wallpaper of various brands. We offer you a selection of manufacturers who have won the trust of buyers.

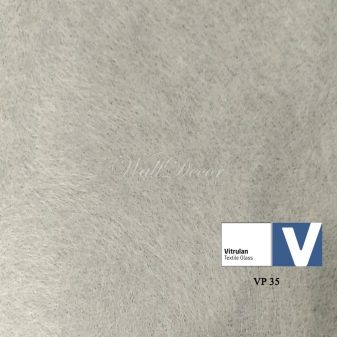

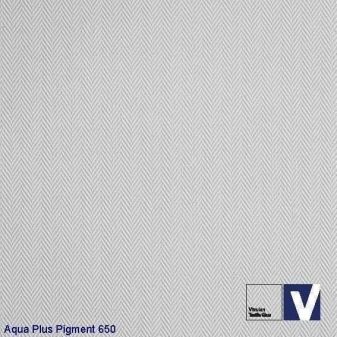

Vitrulan

The German company occupies a leading position in the production of fiberglass. Vitrulan is engaged in the production of wallpaper, including water-active, the assortment is replete with materials and tools for painting, as well as variations of fiberglass. The manufacturer also produces already painted canvases, fiberglass, which imitates fabric textures, has a varied relief.

Buyers note the high performance properties of the material and, importantly, the absence of fiberglass chips when cutting and installing the blade. Finally, the manufacturer produces material with a wide variation in density - from 25 to 300 g / m2,

The company regularly updates its assortment offering innovative solutions. So, those who do not want to bother with glue can purchase glass cloth from the Agua Plus collection. It already contains an adhesive. It can be "activated" by wetting it with plain water. After that, the glue appears on the surface of the "spider web", it is ready for gluing.

The disadvantage of the product can be considered a high price. The cost of even unpainted canvases starts at 2,000 rubles per roll.

Wellton and Oscar

The products are manufactured by the Alaxar production group, which unites leading companies from Germany, Finland, and Sweden. The main activity is the production of wall and ceiling coverings.In addition, related products and tools are produced.

The brand boasts a wide range of premium materials as well as more affordable options. Of the features - a wide selection of material in terms of density (from 40 to 200 g / m2), the ability to purchase material by meter, as well as its high performance properties, including the possibility of multiple staining.

Together with the fiberglass, you can pick up glue for fixing it from the same manufacturers, which is very convenient.

The cost of the material is lower (about 1,500 rubles per roll), but it tends to crumble, and therefore requires overalls for installation. There are minor defects on the surface of the fiberglass.

Of the domestic manufacturers, the products of the companies "Technonikol", "Germoplast", "Isoflex" deserve attention. The first manufacturer offers increased strength fiberglass, which is successfully used for the decoration of industrial premises, roofing insulation, as well as heavily damaged surfaces. The advantage of the majority of domestic glass fibers is their affordability.

The Russian manufacturer X-Glass is one of those who manufacture glass non-woven liners in accordance with European requirements. It is distinguished by its versatility of use, perfectly reinforces surfaces, hiding small and medium cracks and preventing the appearance of new defects. The collection of the brand is not as diverse as compared to European competitors, but X-Glass products are notable for their affordability. In other words, this is an excellent option for low-cost repairs without compromising on the quality of the coating.

Reviews

According to independent consumer ratings, the leading positions are occupied by Oscar brand fiberglass, slightly inferior to them by Wellton products. Many users note that the cost of the roll is above average, but the higher price is compensated by the impeccable quality of the material and the ease of its application.

Wellton fiberglass is actively recommended for stickers on ceilings and plasterboard surfaces., noting the ease of application, good adhesion rates, the ability to carry out subsequent finishing work on the next day. Among the disadvantages is the appearance of stabbing fiberglass particles during installation.

Those who are professionally engaged in apartment renovation strongly recommend using Wellton, especially in new buildings. It is important to carefully protect your hands and face from glass dust, ideally - wear protective clothing.

It is better to refuse to buy cheap Chinese and domestic glass fibers. The material creeps away under the action of glue, requires considerable effort to fix it, and with further painting at the joints it sometimes clings to the roller and lags behind the wall.

Preparatory work

Gluing fiberglass is a simple process that you can do yourself. Before starting work, make sure that your hands are protected with gloves and that your breathing organs are protected with a respirator. This is because fiberglass can form particles when cut. They can cause burns if they come into contact with the skin.

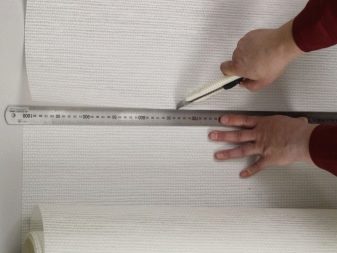

The use of the material begins with its cutting. The size of the piece of material you need is one that is comfortable to work with. As a rule, fiberglass is glued to the wall immediately from ceiling to floor. However, you can divide it into 2 parts and glue them one on top of the other. To fix the "spider web" on the ceiling, professionals recommend cutting a canvas no more than 1-1.5 m long.

Determine the front of the material before sticking it on. When the roll is unrolled, it will be inside. The outer side (to which the glue is applied) is rougher.

Also, at the stage of preparatory work, the glue should be diluted according to the instructions. Adhesives designed specifically for fiberglass should be used. Each type of canvas has its own glue.Adhesive for non-woven wallpaper is also suitable, it will hold glass fleece of any density.

Usage

Fiberglass is used in many types of construction and finishing works:

- wall reinforcement for a better finish;

- preventing the formation of cracks in the topcoat and masking existing cracks;

- preparation of walls for decorative coating - when using fiberglass, you do not need to putty the surfaces with a finishing putty;

- alignment of walls;

- creation of original effects on the surface of the topcoat (for example, marble effect);

- use in roofing works as a basis for bitumen mastic (special types of material are used that improve the adhesion of the roof and mastic);

- pipeline protection;

- waterproofing works - fiberglass is used to strengthen and protect polyethylene sheets;

- organization of drainage systems.

The material is suitable for application to any surface - concrete, plasterboard, and can even stick on top of a layer of old paint (it is better to scratch grooves on it to improve adhesion).

The use of the "cobweb" is recommended especially for those surfaces that are exposed to constant mechanical stress. Wallpaper, paint and other materials, fixed on top of glass fiber, will last you longer without changing the original attractive appearance, even if the structure shrinks.

The glued web of "cobweb" allows you to abandon many operations. You do not need to prime the surfaces, you also do not need finishing puttying (if you do not plan to glue the wallpaper). If the walls are relatively flat, without potholes, then it is enough to fix the fiberglass.

The glued fiberglass dries quickly, and the application of subsequent finishing will be faster. This will save you time and effort on repairs.

It is ideal for under-ceiling applications as it will provide a flawless finish to your finish. The fiberglass mat glued to the outer corners will help to quickly and beautifully stick the wallpaper in this area.

Advice

When applying the glue to the glass mat, it is better to apply it a little wider than the material's width, as it absorbs the glue quickly. When gluing the canvas to the wall, iron it well with a clean cloth, and when it “grasps” a little, run it with a spatula. This will help eliminate air bubbles from the space between the web and the base. After the fiberglass is securely attached to the wall, apply glue to the front side so that it darkens with the glue.

The canvases are glued with an overlap, and after they dry, all protruding parts of the overlap should be cut off with a well-sharpened sharp knife. As a result, a flat surface should remain.

After the canvas is completely dry, you can proceed to the finishing. Since the "cobweb" absorbs paint, you will have to apply it in 2-3 layers, paying attention to the joints. It is recommended to purchase a special "wing" for coloring them. Preference should be given to water-based paints, applied with a roller or wide brush. Application of the next layer is recommended 10-12 hours after the application of the previous one.

If desired, the fiberglass can be pasted over with wallpaper, however, first the surface should be putty. By the way, applying a layer of putty before painting will help reduce paint consumption.

When choosing fiberglass for the ceiling, preference should be given to a material of lower density - 20-30 g / m2 is quite enough. For wall decoration, denser canvases are suitable. Usually, for repairs in a private or apartment building, glass fiber with a density of 40-50 g / m2 is sufficient.

When the canvas dries, it is unacceptable that there is a draft in the room or heaters and other additional heat sources are turned on.

Beautiful examples in the interior

The main purpose of fiberglass is a reinforcing function, however, using certain techniques, you can achieve interesting style solutions. For those who want to achieve original surfaces, it is recommended to pay attention to European fiberglass with a certain texture.

You can achieve an interesting effect by applying the paint directly to the "cobweb" in a thin layer. The result is an original textured surface. The image in the photo is given with a high magnification, in reality the texture is not so pronounced

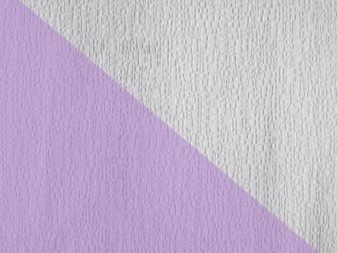

If you need perfectly smooth surfaces for painting or wallpaper, use a putty. Thanks to this technique, you can get a flawless ceiling and walls. On such surfaces, you can safely use bright glossy shades, which, as you know, are very demanding on the evenness of working bases.

You can get interesting effects by applying embossed fiberglass and applying paint directly to them. For structural materials, it is recommended to choose saturated shades - burgundy, chocolate, blue, violet. On light beige surfaces, the relief is usually "lost".

The use of glass fiber for painting is an excellent solution for bathrooms. It will cost much less than tile cladding, but it will look no less attractive. In addition, due to its water resistance and strength, the coating will last for more than one year. And if you get tired of the bathroom design, you just need to repaint the fiberglass. Both a completely smooth wall and a combination of smooth and textured surfaces look organic.

An equally interesting effect can be achieved by painting the same relief surfaces with different shades.

Finally, with the help of fiberglass, you can achieve the effect of marble surfaces.

What is fiberglass for and how to glue it, see the video below.

Thanks! Very detailed!

The comment was sent successfully.