Composition and proportions of expanded clay concrete

Concrete solutions are in demand in all branches of construction. Expanded clay concrete is an excellent analogue of the classic concrete mortar. The peculiarity of the material is the presence of clay granules instead of fine gravel.

What does the solution consist of?

To prepare high-quality expanded clay concrete, you will need the following.

- Expanded clay component. The particle size should not exceed 20 mm. This is the only way to achieve the required strength and density of the material.

- Concrete. Material of class B15 and higher is suitable. With its help, it will turn out to speed up the kneading process, and also make it easier to lay the mixture into a mold.

- Cement. Required to increase the tenacity of the material and the speed of its solidification.

- Sand. In this case, it is worth giving preference to quarry sand, which will fill the voids between the expanded clay particles.

- Water. It should be cool and clean. The presence of impurities in the liquid will impair the concrete hardening process.

If necessary, sawdust or ash is added to the composition. When mixing a mixture of expanded clay concrete, first add components without water to the container. At the end, a liquid is poured in, which makes it possible to obtain a mixture of the desired consistency.

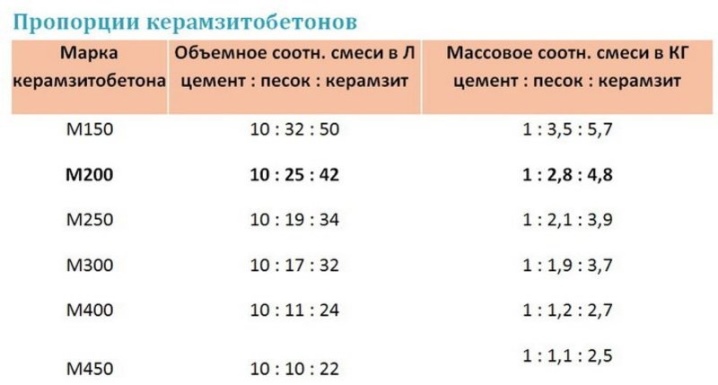

To obtain high quality expanded clay concrete that will be able to cope with the task, it is necessary to first calculate the proportion for mixing the ingredients. It is worth noting that experienced builders have already calculated the optimal amount of mixture for 1 cubic meter. In the network you can find a table through which you can get the claydite concrete of the desired brand.

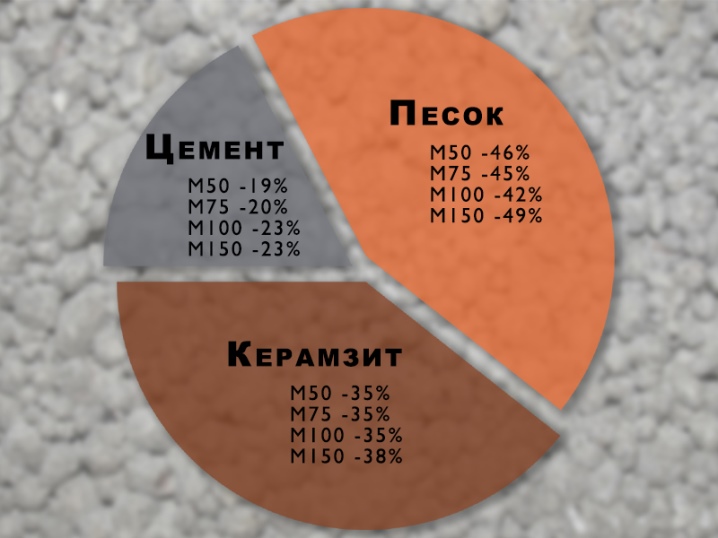

The ratio of components in the table is determined by where you plan to use the material. The optimal proportion of concrete: 1: 3.5: 4.5, where 1 is one part of cement, 3.5 is three and a half parts of the sand seal and 4.5 is four and a half parts of expanded clay. Water is added mainly at the end in the range of 1.5 parts. The table shows the proportions for concrete grades M100, M150, M75, M50, M250.

Expanded clay concrete is a versatile material in demand in the construction industry. The mixture allows you to adjust the density of the final building material, which makes expanded clay concrete so popular. This type of concrete is used in the following works.

- Erection of monolithic or block walls in construction. Lightweight expanded clay concrete solution will make it possible to make durable blocks, panels and other structures. Basically, baths are built from this material.

- Floor screed device. To achieve the required concrete strength, a special mixing ratio of the ingredients is used.

- Floor slab production. The assembly of the structure is carried out using injection technology. Plus of expanded clay concrete slabs is the thermal insulation of the material, which allows you to maintain the desired temperature in the room. Also, expanded clay slabs are lightweight, resistant to moisture and have a long service life.

- Installation of foundations. For the assembly of strong foundations, special expanded clay concrete is used. When mixing the solution, Portland cement is added to it.

In the case of making blocks from expanded clay concrete, preparation of special forms will be required. It is necessary to pour the finished mixture into them, and then compact the composition by means of a vibration device.

How to do it for different purposes?

Expanded clay concrete is a popular mixture that is used not only for assembling building blocks. Material advantages.

- Low weight of finished products. The porous structure of expanded clay makes the density of the finished structure less, due to which it becomes lighter. To install expanded clay concrete blocks, it is not necessary to mount bulky foundations, since the load from such walls will be small.

- Excellent strength indicators. Expanded clay concrete is actively used in low-rise construction, constructing walls, floor slabs, floors from it.

- Good thermal insulation. This parameter allows the use of expanded clay concrete structures in the construction of residential buildings or baths. It is noteworthy that the material retains heat better than classic concrete.

- Reliable sound insulation. With the help of expanded clay concrete walls, it will be possible to protect the room from extraneous noise from the street.

- Environmental friendliness. For the manufacture of expanded clay concrete products, clay and expanded clay are used. The components of the mixture do not emit harmful substances into the environment, which makes the use of blocks and other structures safe for health.

- Long service life. Expanded clay products can serve for more than 25 years without collapsing or deforming.

- Low price. The low cost of expanded clay makes the material affordable and in demand.

- Ease of manufacture. You can make the mixture yourself. For this, shovels are suitable, if it is not possible to organize the mixing of components in a concrete mixer. The simple technology for the manufacture of expanded clay concrete blocks with their own hands made the material popular.

- Convenience of finishing. Plus of expanded clay concrete products - high surface adhesion. This means that a plaster mixture of any composition will adhere perfectly to the walls or ceiling.

Its high performance material is suitable for a variety of purposes. Expanded clay concrete is often used for flooring, erection of both monolithic and block floors. The purpose of using expanded clay concrete determines its composition and manufacturing method. It is worth considering in detail how to prepare each concrete option in building conditions.

For floors

Pouring floors requires the use of a special mixture of expanded clay concrete. Standard proportion for slabs:

- cement - 1 part;

- sand - 4 parts;

- expanded clay - 5 parts;

- water - 1.5 parts.

You can increase the elasticity of concrete by adding a plasticizer to the bucket where the mixture is located. There are several requirements regarding the use of expanded clay concrete for the assembly of slabs.

To build the formwork, you need to prepare the steel sheets. It is desirable that they be profiled. You will also need I-beams and plywood. To achieve the required strength of the material, you will additionally have to purchase fittings. The order of work on the construction of the floor involves the following stages:

- first, load-bearing beams are laid - they will act as the basis of the future overlap;

- metal sheets are spread over the beams, which will play the role of the bottom of the formwork;

- plywood is used to construct formwork side walls;

- a reinforcing mesh is laid inside - the frame of the floor slab;

- prepared solution is poured into the formwork.

The concrete slab should not interact with moisture and dirt. For this, it is necessary to provide for the presence of a waterproofing layer. Waterproofing materials can be purchased at the store. The device of the waterproofing layer will help speed up the hardening process of the mixture, which will allow you to obtain a high-quality monolithic structure of the structure.

For walls

It is no secret that for the construction of vertical surfaces, the composition of expanded clay concrete will need to be changed. The solution should have a denser consistency. The recipe for the mixture for the construction of monolithic walls requires the preparation of the following ingredients:

- cement M400 - 1 part;

- sand - 1.5 parts;

- fine expanded clay - 1 part;

- water - 1 part.

This proportion will help to achieve maximum strength and speed up the hardening process of the material. It should be noted that the solution is suitable for the construction of walls in low-rise buildings. The maximum height of the structure should not exceed three floors.

For floor

Pouring the floor in the house requires compliance with certain conditions. First, the pouring mixture must be mixed in strict accordance with the established proportions per 1 m3. The composition can be mixed with a concrete mixer or manually.

The proportion of concrete mix for the floor:

- cement M500 - 1 part;

- fine gravel - 2 parts;

- expanded clay sand - 3 parts;

- water - 1 part.

Water is added at the end when the rest of the ingredients are thoroughly mixed. Several features are worth highlighting.

- When using metal or iron parts in the process of arranging the floor, you can add any brand of concrete to the mixture. The required strength will be ensured in any case.

- To ensure the solidity of the floor, it is necessary to add a ball from the thermal insulation component. The choice of a component should be carried out based on its characteristics.

- Laying wood planks to create a floor will require an extra layer to prevent moisture from affecting the wood.

Taking into account the features will help make the coating strong and durable. Also, such a concrete formulation is suitable for a blind area. It turns out to be durable and able to withstand climatic and mechanical influences.

Recommendations

To get a high-quality expanded clay concrete mixture, it is worth considering a number of recommendations from specialists.

- Use washed sand to create the mixture. Such a material will make the concrete shrink better and will also increase the strength of the material.

- For reliable preparation of the mixture, it is better to use a concrete mixer. It is also possible to manually mix the ingredients of the composition, but the quality will be lower.

- When working with a concrete mixer, the order in which the components are fed must be observed. First, you need to pour water into the container, then cement, then sand. The last ingredient is expanded clay. It needs to be added only after the other three form a homogeneous mass.

- If shovels are used for kneading, then the sequence of adding the ingredients can be skipped. However, in any case, expanded clay concrete should be added only after a high-quality DSP is obtained.

- If it is necessary to increase the strength of the expanded clay concrete mixture, it is worth adding reinforcement.

Taking into account the listed recommendations will help to achieve high quality of expanded clay concrete and the reliability of the product or structure that is formed from it.

Expanded clay concrete is a material in demand in the construction industry, the advantage of which is its low density. The mixture for the manufacture of expanded clay concrete is selected depending on the construction task, which determines the correct proportions of the components.

For information on how to prepare expanded clay concrete, see the next video.

The comment was sent successfully.