The subtleties of the process of finishing the facade with wood

The "stone jungle" of big cities draws all the energy out of a person, so at least on weekends you want to get closer to nature. It is good if you have your own summer cottage with a wooden house or a private cottage. Natural materials of such a home will help you to relax in ecologically clean conditions. And there is simply nothing more comfortable than a room with a wooden finish. The wooden cladding of the house will organically fit into the minimalistic style of the building, as well as suitable for ordinary summer cottages or stylized "antique" cottages.

The facade of the house can be called the hallmark of every owner, therefore, it is worth approaching the exterior decoration of the home with complete seriousness. In addition to the aesthetically attractive appearance of the building, it is also important that the house is warm and environmentally friendly for living. That is why opt for a wood facade finish.

If, due to the high cost of the material, not everyone is able to build a wooden blockhouse, then almost any summer resident can afford to sheathe a home with wooden panels. Technically, the process of cladding with wood from the outside is not so complicated, so even an untrained master will be able to complete the facade work as soon as possible.

Advantages and disadvantages

Wood finishes, like any other finishing material, have their pros and cons.

Among the advantages, we note:

- environmental friendliness;

- the possibility of combining with other finishing materials in the cladding - for example, stone or brick;

- the ability to "hide" under the tree the imperfections of the supporting structures and a thick layer of insulation;

- with proper processing, wooden cladding will reliably protect the house from negative external influences;

- there is no need to install ventilation ducts, since the wooden surface is perfectly ventilated by itself;

- elegance and respectability of the surface;

- variety of design solutions.

There is, in fact, only one drawback - the flammability of a material such as wood. But we can easily solve it with the help of special protective coatings, which will have to be applied to the building from year to year.

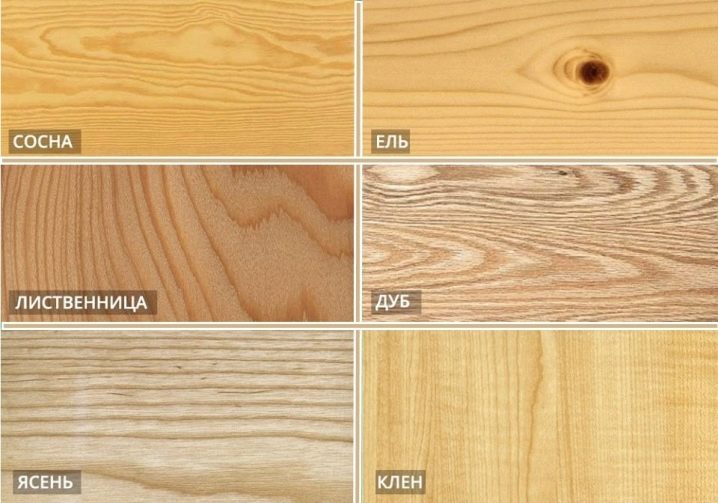

Material breed selection

Before starting facade work, decide what kind of wood you will use, because each material has its own characteristics, advantages and disadvantages. Make a start from the general style and design direction, so that the house looks as harmonious and effective as possible.

The choice of wood species is very important. Do not overestimate exotic wood species - opt for Russian traditions in the construction of log cabins. Only trees growing in central Russia are suitable for any climate in our country.

Pine has soft wood, so the process of processing it is simplified as much as possible for the master. Experts recommend using this material in humid climates, since resinous conifers are resistant to the negative effects of moisture and decay.

The strongest and most durable wood is cedar. It also has an unusual yellow hue, which can be effectively played in the design of your home.

Oak can be considered an elite material, which is not available to everyone due to its high cost.It is distinguished by high strength and durability, besides, oak wood can be of various shades - from golden yellow to dark brown, so you probably will not have any problems with the choice.

Larch has a very strong yellowish wood. Due to the durability of such a material, it is often used for the construction of large-scale objects - for example, temples. Unfortunately, over time, under the influence of the external environment and precipitation, larch wood can darken, so take this into account when building your home.

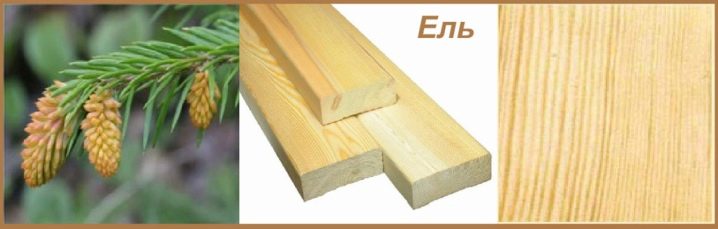

Spruce has a light structure, sticks well, but can eventually start to rot without regular maintenance and treatment with special agents. Alder has a soft texture and is well processed, but also easily rotted. An innovation in the building materials market is thermally modified wood, which is obtained after processing wood under high pressure.

Types of cladding

Exterior decoration, as you know, can be wet technology (for example, using plaster) or hinged technology (cladding with wood panels, siding or other finishing materials).

- Block house

In appearance, this finishing material is a log treated with an antiseptic and varnish, divided in half lengthwise. With the flat side, it is attached to the facade due to grooves-tenons on the sides. This installation technology allows you to assemble a house in the shortest possible time. If you use screws or nails, be sure to treat them with a special anti-corrosion compound.

- Siding

A very popular and inexpensive finish is wood siding. It comes in the form of a molded profile from several connected parts, or it can be made of a solid wooden board. And the ease of installation allows even a non-professional builder to finish finishing - of course, with the help of competent instructions and professional advice that can be found on the Internet.

- Wooden shingles

The cladding with wooden shingles looks very impressive. In addition, such a finishing material will significantly extend the life of the building and protect it from adverse weather conditions. The decoration of such a facade is subject only to specialists who have undergone special training, so you should not experiment and save on the services of professionals.

- Thermal tree

Such material can be used not only for the manufacture of decorative elements, for example, stairs, beams, arbors, rafters, panels. Thermowood can also be used as a facade finishing material. Wood that has undergone a special heat treatment is used to reliably protect the house from negative external influences, humidity and temperature extremes. After all, since the days of Ancient Russia, burnt wood has been used to increase the strength of structures.

- Euro lining

The cladding of the building with eurolining is simple - this work can be done independently, since the boards are connected by the “thorn-groove” fastening system. Such an exterior finish looks beautiful and at the same time is affordable. This material is distinguished by its low weight, which means a faster installation speed.

- HPL panels

This material is a combined finishing raw material obtained by pressing cellulose and wood fiber, which are impregnated with heat-shrinkable resins to improve technical characteristics. This material is produced at a high temperature, so the sheets are super strong.

As advantages over other materials, it is possible to note resistance to shock and mechanical damage, as well as to negative environmental influences. Such a facade will serve you faithfully for many years, and caring for it will take a minimum of time and money.

Since HPL panels are lighter than other façade materials, they are often used for large surfaces.A wide range of colors and a rich selection of textures will allow you to choose panels for any interior style. Another advantage is the "self-sufficiency" of the panels, that is, you do not need plastering or additional processing of such a facade.

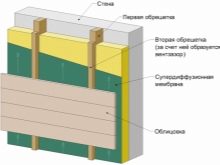

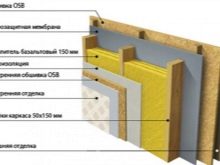

- Ventilated facade

Another innovation is a ventilated facade, when the brackets for the lathing are first mounted on the walls, then insulation and a lathing made of timber are placed. As a result, a kind of air cushion is formed inside, which ensures natural ventilation of the wooden facade.

A membrane is attached to the crate to protect the insulation from the ingress of condensation and the formation of fungus. Note that the absorbent side is attached to the wall of the house. And at the end, the wooden finishing material is fixed to the crate with the help of special fasteners.

Finishing

After completing the installation work, be sure to cover the wooden surface with special protective equipment. Facade varnish can be alkyd or polyurethane with antiseptic fillers against the formation of fungus and the appearance of harmful insects. All of these characteristics are possessed by a yacht varnish.

Oil varnish will save money, it is resistant to sunlight, precipitation and temperature extremes. An alkyd varnish will help prevent wood cracking. Water-based varnish is the most environmentally friendly and harmless. At the same time, a wooden surface treated with such a tool will be reliably protected from external influences and mechanical damage.

When treating the facade with varnish, read the instructions and take into account the wishes of the manufacturers, at what temperature it should be applied, so that the varnish is absorbed according to the rules and, accordingly, the quality of the wooden finish of the house does not suffer.

Another popular facade coating option is the so-called azure coating., which will protect the facade from the effects of precipitation and sun. In doing so, you can give the house different color nuances. The protective properties of glaze are preserved for about 5 years, after which the treatment is repeated.

See below for more details.

The comment was sent successfully.