All about hardboard

Hardboard is a type of fiberboard, differing from ordinary fiberboard material in a higher degree of density of highly compressed fine fibers. Despite its porous structure, hardboard is a hard and durable material that is used for construction and finishing works, as well as used in the manufacture of furniture products.

Peculiarities

Hardboard is not considered an independent nomenclature unit and is not separately regulated by state standards. This sheet product of woodworking is a type of fiberboard, the manufacturing technology of which and quality standards fall under the standards of GOST 4598-86.

Externally, hardboard looks like a material in which one side is smooth and the other is rough.

Composition

The material is based on wood waste products - crushed to a minimum fraction of wood fibers. These components are mixed with an adhesive polymer composition and pressed under high pressure. The glue mass contains formaldehyde, which, when evaporated, is harmful to human health. The laminated coating, which is applied to some grades of hardboard, significantly reduces the harm from formaldehyde, preventing its evaporation and improving the properties of this material.

The composition of the wood fiber material includes a number of ingredients.

- Phenol-formaldehyde resins and polymer binders. They glue together wood fibers, and also give the material high density and strength.

- Pectol (a product of processing of the tall oil component), as well as other polymer compounds that increase the resistance of the material to mechanical stress.

- Antiseptic compoundsthat affect the resistance of wood fibers to the effects of fungus, mold and prevent decay processes. These additives also increase the moisture resistance of the material.

- Fire retardants - substances that give the material a certain fire resistance.

- Hydrophobic additives in the form of paraffins, rosin resin and others. The components provide the material with water repellency.

According to the technical documentation, hardboard contains no more than 1.3% of the binder adhesive relative to the total mass of the material. In addition, only low-toxic components can be used in the composition of polymers.

Specifications

According to the GOST standards, materials related to hardboard are divided into 3 main types.

- Soft hardboard, marked with the letter "M". The weight of this material is small, due to its low density, which is 100-500 kg / m². If you look closely at the surface of the leaf, you will notice its porosity, like that of cork. This hardboard is used for interior decoration. With its help, they equip partitions, level the floor, ceilings or walls.

- Hardboard, marked with the letter "T". Due to its high density, which ranges from 500 to 800 kg / m², the material is positioned as moisture resistant and can be used not only for decoration, but also for construction needs. Outwardly, this material looks like a solid sheet of technical cardboard. Moisture resistance is especially well pronounced in varieties of this material that have a film lamination of the surface.Dense sheets are used for the manufacture of container boxes, as well as in furniture production.

- Superhard hardboard, marked with the letters "ST". Its density ranges from 800 to 1100 kg / m². The structure of such a material has a reinforced monolithic strength, therefore, hardboard is used in the construction industry, in the production of furniture products, for the manufacture of interior doors and for other needs.

To improve the appearance of fibreboard during its production, film lamination is used, as well as surface coating with paint or varnish.

The most popular option is hardboard without adding any finishing components. This sheet of natural beige color is often used to make the back walls of drawers or cabinets, transport boxes and other container products are made with its use, and also used in construction and finishing works.

The moisture resistance of different types of fibreboard differs depending on their density. For example, a semi-solid material marked with the letters "NT" can be in water for more than a day and at the same time it swells by only 40%, and the superhard type "ST" under the same conditions will swell by only 15%.

Production

Hardboard fiber sheets are made by pressing under the influence of high temperature conditions. The crushed wood fiber components are combined with a hot polymer adhesive. After thorough mixing, the composition is subjected to the action of a defibrator, which explosively breaks down the components of the material. After this stage, finished sheets are cast from the resulting composition in special molds, which are placed under a hot press with high pressure. The next stage of production is drying the sheets in a special drying chamber.

The hardboard production technology is somewhat similar to the MDF manufacturing method. The difference is that the preliminary steaming of the fibers promotes their better splitting, which, in turn, makes it possible to produce even very thin sheets.

Applications

Hardboard is widely used in various spheres of economic sectors. This material can be used as a light partition inside the room, the ceiling is leveled with hardboard sheets, it can be used for the walls of the kitchen, preparing them for the tiles. The density of the material makes it possible to use it for artistic purposes. For example, a picture painted with oil paints can have a hardboard base.

When carrying out repair work, fibreboard can be used for rough leveling the floor before laying laminate or laying parquet boards.

Hardboard sheet can be used as a heater when sheathing the walls of a country house. Besides, it is also known as a furniture element, without which it is difficult to imagine a modern wardrobe or even its separate drawer. For furniture, thin and hard types of material are used, they are widely used by manufacturers, due to their strength and low cost. Sheets of wood-fiber material are used for interior decoration of railway cars, cabins of sea liners, interior arrangement of motor transport passenger vehicles.

In the field of cargo transportation, hardboard is an irreplaceable material from which crate is made when packing goods, shipping boxes and tare boxes are made. The availability of the material, as well as its low cost and ease of cutting, explain the wide scope of use of hardboard.

Varieties and labeling

As already mentioned, hardboard is considered a type of fiberboard, therefore it is subject to standardization in accordance with GOST 4598-86. We have already touched on the topic of marking a little. Let's dwell on it in more detail. Depending on the strength and design options, hardboard is marked as follows:

- hard, with the front surface of the untreated type - grade "T";

- hard, with the processing of the front surface with a finely dispersed mass of wood - brand "TS";

- hard, with a coating of the front side with paint - "T-P" brand;

- solid, made of wood components of fine dispersion, has a painted front side - brand "T-SP";

- solid, resistant to moisture, with an untreated surface - brand "T-B";

- solid, made of wood components of fine dispersion, resistant to moisture, with a painted front surface - brand "T-SV";

- low hardness sheet - grade "NT";

- sheet of superhardness and high strength, the front side is not processed - grade "ST";

- superhardness sheet made of wood components of fine dispersion, refined on the front side - "STS" brand.

Hardboard, which corresponds to the brands TS, TSP, TP and T, in turn, is divided by the quality of the processing of the front surface into 2 grades - I and II. Refined hardboard can be double-sided. Some brands have a laminated finish or decorative perforation.

Perforated material is used in furniture production or as a finishing material for rooms - for example, it can be a screen for a heating radiator.

Sheet sizes

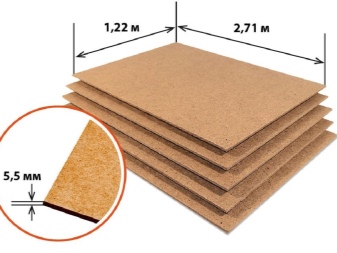

Hardboard panels have a standard size, but it varies depending on how thick the sheet is. The most common indicators are dimensions from 1.2 to 6 m in length and from 1 to 1.8 m in width. Large-sized panels are most often used for construction or industrial purposes. For household needs, hardboard is used, the length of which is 2140 or 2750 mm, and the width is 1220 mm.

In the manufacture of fiberboard, GOST standards allow minor deviations in its dimensions.

- For soft types of material, the discrepancy in length and width is permissible within 5 mm, both upward and downward. As for the thickness, its error can be no more than 1 mm.

- For solid types of material, the discrepancy in length and width is permissible within no more than 3 mm, both upward and downward. In terms of thickness, the error is also allowed within 3 mm.

According to GOST standards, the maximum length of hardboard is 6100 mm, and its width cannot exceed 2140 mm. This material is always thin in thickness - its maximum size is 6 mm.

Design

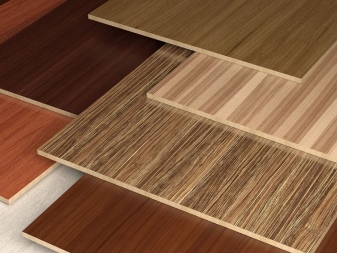

Refined sheets of wood-fiber material have a decorative coating on the front surface. Hardboard sheets can be impregnated with dye under production conditions at the stage of preparing the mass for pressing. This technique allows you to achieve the durability of the dye and its high-quality distribution throughout the material. The most versatile and popular is white hardboard, the second most popular is black.

For decorating sheets of wood-fiber material, a film is used. Its color performance can be different - it can be transparent or colored. Film with a pattern can imitate the texture of wood, stone or ceramics.

Refinement of hardboard is carried out by coating its front side with varnish - this method allows you to create a glossy or matte surface, depending on the type of varnish applied.

The cost of a decorated hardboard for 1 sheet will be much higher than the price of an ordinary sheet without special processing. But such costs pay off, since the refined material acquires a number of valuable advantages:

- decorative coating protects the hardboard sheet from scratches, chips and moisture;

- the laminated material can often be subjected to hygienic processing, while it is easy to clean and does not absorb foreign odors;

- protective treatment extends the service life of the wood fiber material up to 20 years;

- a variety of colors and textures can significantly expand the range of applications of the material and increase its aesthetic qualities.

The main qualities for which a wood-fiber product is valued are its durability of operation, resistance to mechanical stress, moisture resistance and practicality in use. All these properties are combined in one material, which has a rather low cost.

How to choose?

Hardboard is offered by almost any specialized retail outlets, so it will not be a problem to purchase this product. But when choosing sheets of this material, it is necessary to take into account some important nuances.

- The working dimensions of the sheet are 2140 by 1220 mm and have a thickness of 2.5 or 3.2 mm. Custom sizes can incur high trade margins.

- Grade II material can have dimensions of 1700 by 2745 mm, while its price will be the same or slightly lower than that of a sheet with standard I grade dimensions.

When choosing during the purchase process, it is recommended to carefully examine the material. A quality I grade product should not have chips, scratches, creases or cracks. Pay attention to the presence of dimples or bends in the sheet.

If the waviness is too pronounced, it is better to refuse to buy.

Operating tips

Hardboard material is used only for indoor work and dry rooms; this product is unsuitable for outdoor use. When choosing a material, you need to determine what hardness you need. Even the hardest sheet can be cut to size at home. To cut the fibreboard, you need a regular jigsaw or circular saw. The cut of the material with these tools is smooth, without chipping and torn edges.

If necessary, a dry sheet of hardboard can be painted with paint or varnish. Today, this material has become ubiquitous for repair or decoration work carried out in houses and apartments. Hardboard ceilings, walls or floors have become a common feature in private homes, outbuildings or warehouses. To perform facing with hardboard, a frame of slats is preliminarily installed on the surface to be decorated, only then sheets of material are fixed to it. Ordinary nails or self-tapping screws will help to fix the material. Unlike fiberboard, hardboard is a lighter material, so it is easier to use in work.

In some cases, the sheets of hardboard can be fixed with glue - for example, this is done when decorating walls. Previously, the surface of the wall is cleaned of plaster, putty or old wallpaper, only then the adhesive is applied to the wall and to the material itself.

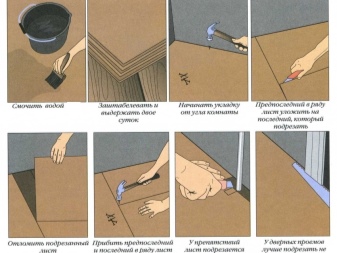

For hardboard flooring, you can adhere to the following technology:

- moisten the surface of the sheet with water using a paint brush;

- lay the sheets evenly in a stack on top of each other, then let them dry at room temperature for 2-3 days;

- when the sheets of material become perfectly even, they begin to lay them from the far corner of the room;

- in order to correctly adjust the length of the last sheet, it is laid on the previous sheet and cut with a sharp knife, and then broken off;

- sheets are nailed to the crate;

- at the junction of the sheet with the door casing, it is recommended to cut not the sheet, but the door casing itself.

Hardboard allows you to perform the required amount of work rather quickly and without large cash costs. This wood fiber material is reliable in use and has an aesthetic appearance.

About what hardboard is and how to prime it, see the next video.

The comment was sent successfully.