Frame house made of metal profiles: advantages and disadvantages of structures

For a long time, there was a prejudice towards frame houses made of metal profiles. It was believed that prefabricated structures made of profiles cannot be warm and durable, they are not suitable for living. Today the situation has changed, frame houses of this kind are of increasing interest to owners of suburban areas.

Peculiarities

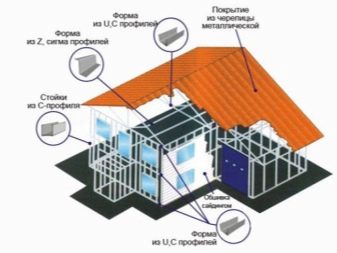

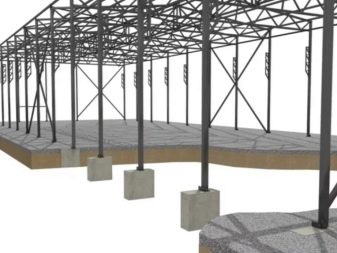

Metal-frame structures, originally used for the construction of warehouse and retail facilities, are now used in private housing construction. The basis of a frame house made of a metal profile is made up of light, but durable structures made of galvanized steel. The thickness of the profiles is calculated individually for each section of the object and depends on the tested loads. Steel profiles provide the structure with the necessary strength, the zinc coating acts as an anti-corrosion protection, guaranteeing the durability of the structure. In order to increase reliability, the profiles are supplemented with special stiffeners.

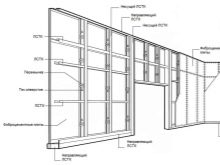

Profiles can have a cross-section in the form of various Latin letters (C, S and Z). Each of them is used in a particular construction site. For example, the base is laid out using C and U profiles, connected with self-tapping screws. The frame pitch is determined by the width of the insulation and sheathing panels used. On average, it is 60-100 cm. The profiles are perforated, which solves the problem of ventilation, increases the thermal insulation characteristics of the object.

They are assembled according to the principle of a children's designer; the construction process itself does not imply the use of special equipment (perhaps, to create a foundation). Having minimal construction skills, you can assemble a house with your own hands with a small number of assistants (2-3 people). Due to the insignificant thickness of the walls of the frame house (on average 25-30 cm), it is possible to obtain a larger usable area than when using standard technologies (houses made of timber, bricks, blocks).

At first glance, it seems that frame metal-profile houses look unattractive and monotonous. However, this is completely wrong, because due to the lightness of the design and the ability to give it a different configuration, it is possible to create objects unusual in their shape. The structural features allow the use of most modern hinged materials for finishing external walls, which can be changed if necessary. If desired, the facade of a metal-profile frame house can imitate stone and wooden surfaces, brickwork.

The house looks stylish and modern, it is not subject to moral obsolescence, since the facade cladding can be replaced at any time.

The cladding can be carried out immediately after the construction of the object, since the frame based on the metal profile does not shrink. The high speed of work is also an advantage. Usually a house for a small family can be built in 2-4 months. At the same time, most of the time will be spent on preparing the foundation and waiting until the poured concrete gains the necessary strength. There is a misconception among the inhabitants about the instability of frame houses. However, such a structure can withstand significant wind loads and is even capable of withstanding a period of seismic activity (its resistance is up to 9 points on the Richter scale).

Another "myth" about frame houses is associated with its ability to attract electricity. From this point of view, frame objects are completely safe - all metal elements are grounded. In addition, the outer and inner steel parts are treated with dielectrics. Among the shortcomings, one can single out the high thermal conductivity of the material. Therefore, one cannot do without high-quality insulation and protection of metal from moisture vapors.

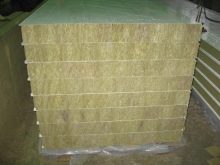

The use of ecowool or mineral wool insulation, as well as the installation of warm facing panels, allows you to optimize the thermal efficiency of a frame house, prevents the formation of cold bridges. Frame houses based on metal profiles cannot boast of durability. Their service life is 30-50 years. Although it is true that the repair of such structures is quite simple, it does not require large investments.

The metal profile itself is characterized by fire resistance. However, the material from the inside and outside is sheathed with a variety of synthetic insulation, vapor barriers, and finishing materials. This can significantly reduce the fire safety of a frame house. The cost of building a frame house is much lower than the prices for building a brick, wooden and even block analogue.

This is due to the smaller volume of material required, the possibility of using a lightweight foundation, the lack of involvement of special equipment and professional builders. A frame house can be made according to an individual or standard project. Of course, the first option will be more expensive, but it will allow you to create an exclusive home that meets all the requirements of its owner.

A typical project is being built according to Canadian technology using a thin-walled metal frame and thermal insulation SIP panels.

Choice of design

Houses based on a metal frame can have several varieties.

Based on rolling

Such a house is characterized by the presence of metal columns on which the entire structure rests. The construction technology is similar to a monolithic frame structure. However, metal columns used for profile technology are lighter and cheaper than reinforced concrete foundations. Most skyscrapers and shopping centers are built in this way. In private housing construction, such a technology can turn out to be unreasonably time consuming and expensive.

As a rule, they resort to it if it is necessary to create an "iron" design house of unusual sizes. Using this technology, you can build a domed or multi-storey building. Often, decorative architectural elements of irregular shape are located around such a house. In most cases, these are masked elements of the frame tube. A house on a welded frame made of rolled metal profiles is characterized by the largest weight among the frame counterparts of the same size, but it also has the longest service life, which reaches 50-60 years.

From a lightweight profile

The basis of such a house frame is thin-walled metal structures, visually similar to drywall profiles. Naturally, the frame elements have a much greater margin of safety. Of the advantages of such buildings, we can note their lower weight, which allows you to save on the preparation of the base, to optimize the construction estimate. Although the reduced mass of the structure turns around and a decrease in the life of the house.

Modular and mobile

Technology developed for the construction of temporary or seasonal objects (summer crowbars, kitchens). It is applicable in the construction of a country house for living in the warm season. The building is based on modules, the frame of which is combined and consists of metal and wood. Mobile buildings involve the installation of a rigid metal frame as a frame.When building a temporary facility and a two-story country house, it is necessary to create a project plan.

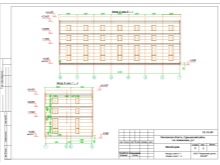

The drawing must reflect all the structural features of the building, the calculation of the bearing capacity of the profiles is required

Construction

The construction of a frame house begins with studying the characteristics of the soil at the construction site and creating a 3D project of the future structure. The three-dimensional image allows you to calculate the required bearing capacity of the main structural elements, arrange them in compliance with the spatial geometry. After that, the order is sent to the plant, where profiles with the required technical characteristics, shapes and dimensions are made for a specific project. Component elements for a frame house can be assembled at the factory or created by hand on a construction site.

The first option will be somewhat more expensive, but then it will take no more than 4-6 days to assemble the house. With self-assembly, you will be able to save a little, but the assembly time will stretch to 7-10 days. After the preparation and approval of the project, you can start organizing the foundation. Any type of it is suitable, the option of a strip foundation is considered optimal, or the use of a shallowly buried slab as a base. After the foundation has gained a margin of safety, they begin to assemble the metal frame of the house. The next stage is roofing work, installation of windows and doors and laying of communications.

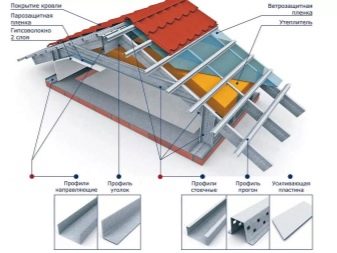

The roof must also be defined at the design stage. It can be flat, single, gable (the most popular options) or have a complex configuration. When organizing the roof, first prepare the rafter system, after which they begin to create the sheathing. Next, the steam and waterproofing layers are laid, the roofing is laid (slate, ondulin, metal tiles).

Before insulation, a windproof film should be laid over the entire surface of the outer contour of the house. Heat-insulating material is placed on it, after which it is the turn of the installation of the facing layer. Usually, all wall gaps are filled with foam or aerated concrete. Spraying with polyurethane foam is possible. When using sandwich panels that initially contain insulation, you do not have to worry about additional thermal insulation of the outer walls.

As a rule, frame houses made of metal profiles are subject to insulation from the inside. For this, the walls are laid with a layer of heat insulator, which is covered with a vapor barrier membrane. Next, drywall sheets are fixed on the crate, plaster and facing material are placed on top of them. As an external cladding, heat blocks are widely used, which do not need additional thermal insulation, ready for applying paint or plaster.

You can sheathe the house with siding, clapboard, overlay with silicate bricks.

Advice

Any type of foundation is suitable for a frame house. However, this does not mean that you can choose it without resorting to a preliminary study of the soil. When choosing the type of foundation, you should always focus on the features and characteristics of the soil. It is necessary to conduct his research at different times of the year. The most common for this type of object is a narrow strip foundation, which is a solid frame. Even when installed on moving soils, the load from the metal frame will be uniform over the entire surface of the base.

The columnar foundation assumes the presence of beams connected to each other. It has a lower bearing capacity and is suitable for clayey soils. If construction is planned on a highly rugged terrain, a pile type of foundation can be recommended. The last 2 options require the involvement of special equipment for driving pillars or screwing in piles. The most economical and less laborious is the implementation of a shallow foundation in the form of a slab. Such a base is optimal for moving soils.

If the use of built-in kitchens and furniture is planned in the house, its location should be determined at the planning stage to give increased strength to the metal frame in the places of their installation. Reviews of those who independently erected a frame house suggest that the assembly of the structure itself does not cause great difficulties.

It is important to follow the project, all structural elements are numbered, which makes installation easier and faster. When laying the vapor barrier, it should be done with an overlap of 10 cm, gluing the joints and damaged joints.

Next, see an overview of the finished metal frame house.

The comment was sent successfully.