Aquapanels: what do they look like and where are they used?

The range of building materials is constantly updated with new practical items with excellent performance characteristics. Not so long ago, special water panels began to be produced. Today they are widely used in construction work. In this article, we will find out how water panels look and where they are used.

What it is?

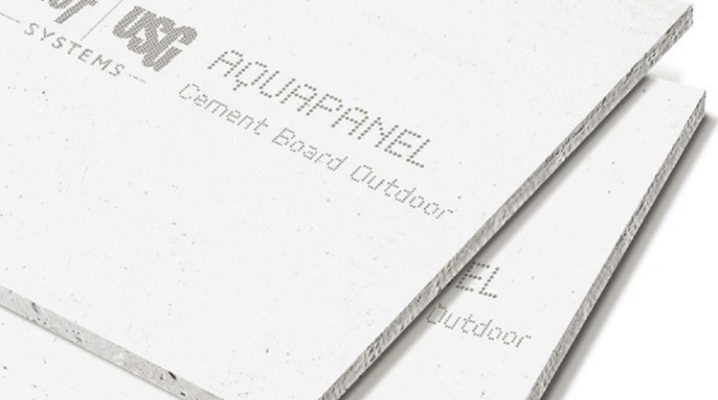

Before getting acquainted with all the parameters and operational characteristics of the water panels, it makes sense to understand what they are. This is a completely new sheet material that has become widely used in the construction industry. Such sheets have planes and end edges that are reinforced.

To achieve high strength parameters, these areas are reinforced with a special mesh-type fiberglass. In the middle of the water panels there is a special core. It is made on the basis of lightweight concrete. High-quality cement slabs are characterized by ideal geometric parameters, which makes it very convenient to work with them without facing unnecessary difficulties.

The very name of the aquapanels indicates that they are distinguished by a high level of resistance to moisture. That is why the materials under consideration are not afraid of high humidity levels or temperature jumps. Aquapanels do not swell, even if they are completely immersed in water. The composition of these products does not provide for components of organic origin, so they are not subject to rotting at all.

In addition, there is no such element as asbestos in aquapanels, so they are absolutely safe for the health of living organisms.

Characteristics and properties

Before using the material on the construction site, it is advisable to initially understand its main quality characteristics and properties. Thus, you can save yourself from all sorts of surprises.

Let's learn about the most important characteristics of modern water panels.

- These building materials boast high strength level... Damaging them is not as easy as it might seem at first glance.

- High-quality water panels are very persistent in relation to mechanical stress, even if the latter are strong enough.

- Considered building materials make it possible to fully veneer even surfaces that are curved.

- Material in the form of slabs does not burn, does not support it.

- On the surface of the water panels harmful microorganisms do not multiply, therefore, the risk of mold or mildew growth is reduced to zero.

- The slabs in question can be safely considered universal... They can be used both inside and outside buildings.

- High quality water panels do not distinguish aggressive and corrosive substances that can harm your health.

- Water panels are possible without unnecessary difficulties slice into individual parts, if necessary.

- Construction material very easy to fit and is fixed by means of self-tapping screws.

- Aquapanels are durable construction products, are distinguished by a high level of wear resistance.

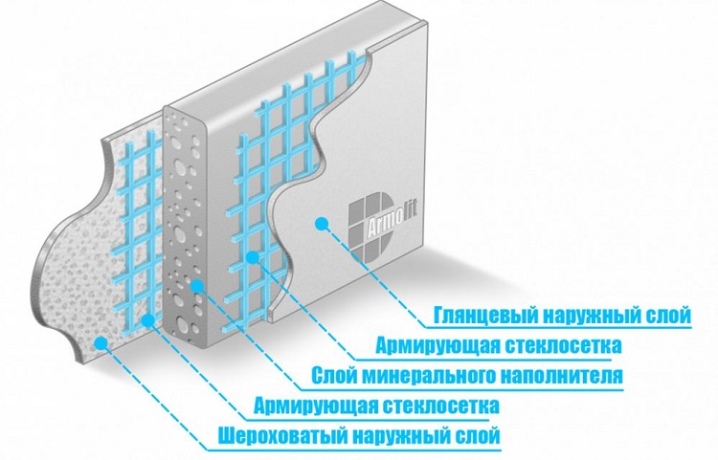

If we consider in more detail the composition of such materials, then the following main components can be distinguished.

- For the inner layer of the water panels, Portland cement is used, as well as a special mineral filler. The addition of plasticizers allows you to achieve a sufficient level of product flexibility, due to which it becomes possible to finish curved bases.

- On both sides of the core there is a reinforcing fiberglass meshmentioned above.

- The outer sheath is cementitious... It is smooth and glossy on one edge and slightly roughened on the other to achieve better adhesion. The finish easily and without hindrance lies on the outer layer of the aquapanel, so it can be painted, decorated with tiles and other coatings.

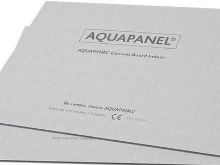

The sizes of such a sheet may be different. Today on sale you can find options with the following dimensional parameters.

- Universal aquapanel... The length of such products is 1200 mm, width - 900 mm, thickness - 6-8 mm, weight - 7-8 kg / sq. m.

- External and internal slabs. The length of these materials can be 900/1200 / 2000/2400 mm, 2500/2800/3000 mm. Width - 900/1200 mm, thickness - 12.5 mm, weight - 16 and 16 kg / sq. m.

- "Skylight" plates. Their standard length reaches 1200 mm, width - 900 mm, thickness - 8 mm, weight - 10.5 kg / sq. m.

When choosing the right type of material, it is very important to take into account its technical characteristics.

Varieties

It should be borne in mind that water panels are divided into several different types. Each category of such building materials is designed for a specific framework of operation, has its own characteristics and characteristics. Let's consider how different types of modern high-quality water panels differ.

Internal

For internal work, such water panels are most often used, the thickness of which is only 6 mm. Similar products can be found in the assortment of the large company Knauf, which specializes in the manufacture of building materials.

The specimens in question are lightweight, but at the same time they are quite durable and reliable.... They are easy to install without any extra effort. The service life of internal water panels is quite long. On sale you can find high-quality Knauf water panels, the thickness of which reaches 8 mm.

These interior slabs are ideal for kitchens, balconies or bathrooms. These products do not deteriorate from exposure to high humidity levels, do not deform, do not change their original shape from the liquid spilled on them. The dimensions of these products are in many ways similar to gypsum plasterboards, but their quality characteristics turn out to be much more practical.

The small mass of internal water panels allows them to be used even for decorating a ceiling base. If you veneer the walls with this material, you will be able to achieve almost perfect surfaces, ready for further finishing manipulations.

The slabs in question can be painted and various finishing materials can be fixed on them.

Outdoor

Aquapanels are often used for finishing frame and monolithic buildings, as well as garages and even summer cottages. The properties of the building material in question make it possible to create different architectural structures with it. Plates are flexible and very durable, therefore they are not afraid of mechanical stress.

External panels are ideal for cladding ventilated façade structures. They can be used as a basis for the subsequent fastening of clinker or ceramic tiles. Other finishing materials for external work are also allowed to be used.

Universal

Today, you can find on sale not only indoor and outdoor models of water panels, but also their universal options. Such varieties are also available in the assortment of the famous Knauf brand. These types of building materials are characterized by their versatility.They fully live up to their name. Universal plates are suitable for both outdoor and indoor use.

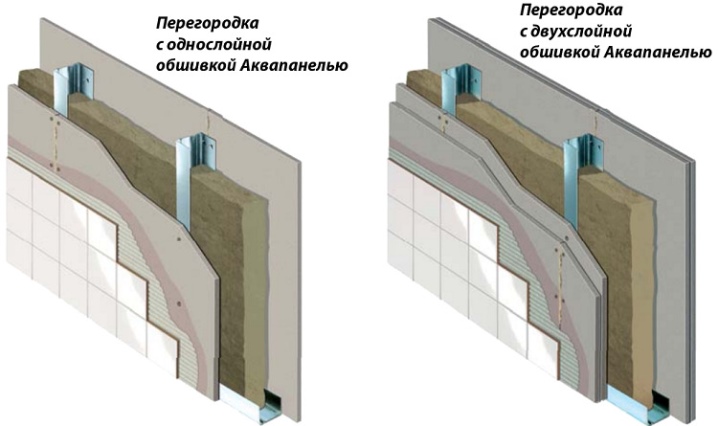

The considered types of water panels are allowed to be used in conditions of temperature fluctuations and humidity levels. In addition, universal plates are often used for the construction and installation of decorative walls and partitions.

Applications

Currently, water panels are very often used in construction work. These materials quickly gained great popularity due to their practical characteristics and resistance to the influence of dampness or moisture.

Let's consider what are the main areas of application of the latest building materials that are rapidly gaining popularity.

- Instances designed specifically for work inside buildings, are used as bases for finishing and cladding, even in damp rooms. We are talking about the kitchen, bathroom, laundry and so on. It is allowed to use even in those areas that are equipped around the pools.

- Materials "sharpened" for outdoor work, used for cladding in frame and panel housing construction.

- There are slabs included in the special series "Skyline"... Similar materials are used for the construction of high-quality suspended ceilings. They are also used in the design and facing of loggias and balcony rooms located in the interior of buildings under construction or reconstructed.

- Modern aquapanels suitable for facing canopies.

- The building materials in question are very often used to build attractive gazebos or sheds. They are also suitable for cladding plinths.

- Aquapanels are very useful when it comes to installing curved type partitions, as well as shafts for organizing various kinds of engineering networks, for cladding various components of a structural type (stoves, fireplaces, slopes, and so on).

Aquapanels are multifunctional. They are suitable for work in a wide variety of conditions. These can be actions in a wooden house and even in a bathhouse.

The materials in question can be used to equip walls, ceilings, shelves, ceilings. Thanks to the wide range of uses, the water panels gained popularity so quickly.

Installation nuances

Before attaching the purchased water panels, you first need to prepare all the necessary tools. You should stock up on:

- pointed screws;

- high-quality self-tapping screws with a drilling end;

- special reinforcing solution (glue);

- white putty.

Let's consider the main stages of correct installation of modern water panels.

- The first step is to clean the base on which the waterproof panels will be attached. It is required with utmost care to remove absolutely all dirt that is on the surface.

- This is followed by the mandatory measurement of the working area, as well as the identification of lines (vertical and horizontal). In the area of the planned location of the waterproof profile, it will be necessary to apply accurate markings.

- In the next step, you will need to mount and securely fix the guide profile. This component acts as the basis for all the other necessary components. Previously, it will be necessary to place a special sealing tape on the part, which ensures better adhesion to surfaces.

- Further, based on the areas where the main parts are located, you may encounter some nuances. The lathing is mounted in accordance with the same technology as in the case of using drywall sheets.

- When the fastening of the frame base is left behind, you can safely proceed to the installation of the water panels themselves. If the size of these building materials needs to be adjusted, then they can be easily cut using a special construction knife.It happens like this: they cut through the fiber, as well as the internal filling, after which the plate simply breaks. On the other side of the sheet, similar manipulations are performed with respect to the reinforcing mesh.

- When it comes to facing wall structures, then all basic work must be started from the bottom.... Plates must be carefully laid, not forgetting about the offset by one profile rack. This is necessary to prevent the appearance of cruciform joints.

- Using a conventional screwdriver, the materials in question will be able to easy to fix on the surface of the base.

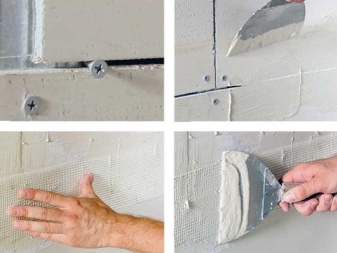

- After that, you can proceed to applying and fixing the selected finishing materials.... It is imperative to scrupulously close up all the seams and joints on the structures.

- Highly recommended carefully hide absolutely all fasteners, which are still noticeable after the correct installation of the water panels.

- It is required to carefully lay the solution on the corner surfaces. After that, these bases are covered with a reinforcing corner profile.

When doing the correct installation of the slabs in question, it is very important to remember that there must be a distance of at least 5 cm between the cement panels themselves and the ceiling base.The gap from the floor and floor coverings is also important - it must be at least 20 mm.

It is required to apply a special polyurethane adhesive solution to the edges of the fixed products, which provides a more reliable and high-quality fastening.

The comment was sent successfully.