All about fire-fighting mastics

Fire-fighting mastic is intended to increase the fire resistance of certain surfaces and structures. This viscous substance is made in the form of a paste and includes various resins containing nanomaterials. We will talk about the features and varieties of the composition in more detail in our article.

What it is?

The consistency of the mastic is a putty. It includes a set of various substances that will help with gluing, are able to seal cracks, cracks and not too bulky holes. With the help of mastics, waterproofing can be achieved in the required places.

Their consistency is quite dense and paste-like.

This composition is distinguished by its elasticity and the ability to bond various building materials together. It is sold both in the form of a dry mixture, which will require additional dilution with water and solvents immediately before work, and in the form of a ready-made solution.

The mastic hardens gradually. This happens for two reasons. First, the solvent can evaporate from it after being applied to the surface. Secondly, the composition contains a mixture of elements, during the interaction of which various chemical reactions occur.

One of the varieties is fire-fighting or refractory mastic. When applied, the fire resistance of the object increases. The scope of use is quite wide. Mastics are distinguished by such characteristics as viscosity, plasticity, non-toxicity, lack of flammability and the ability, after application, to withstand elevated temperatures (depending on the variety, up to 1800 degrees).

Views

High-temperature sealing mastic is presented in several varieties, differing in the field of application and purpose.

Heat resistant

This mastic has a high operating temperature - up to 1800 degrees. Its use is especially important for the installation of furnace structures and heat-generating equipment.

The composition is based on refractory clay and cement mixtures.

As for the negative aspects, such a product is characterized by insufficient plasticity. It does not tolerate shock and vibration, which can lead to cracks. As a result, the sealing layer is destroyed where the structural elements are connected, respectively, the mastic is no longer able to fully perform its functions.

In the construction market, over time, new, improved formulations appear. Some modern types of heat-resistant mastics are used to seal chimneys and all kinds of production equipment. They are widely used in the transport sector, for engines and exhaust ducts, and for stoves, fireplaces.

Refractory

This variety can be called the most popular in the construction market. The scope of its application is incredibly wide. It is suitable for work with chimneys and stove heating, withstands the loads during the operation of heat generating equipment.

Refractory mastic can also be used to seal small holes and cracks.

Refractory compounds are those that can withstand temperatures of more than 200 degrees for a long time. But, for a not too long time, the indicator can increase up to 1300 degrees.This means that the mastic can even come into contact with an open flame, temporarily protecting the treated surfaces without compromising the tightness. It also withstands constant vibration from devices.

Heat resistant

The working temperature of heat-resistant adhesive mastic can be up to 1100 degrees. It can be used to bond various surfaces that will be exposed to higher temperatures in the future. Great for ceramics. It bonds well fire-resistant materials and metal products, brickwork, tiles.

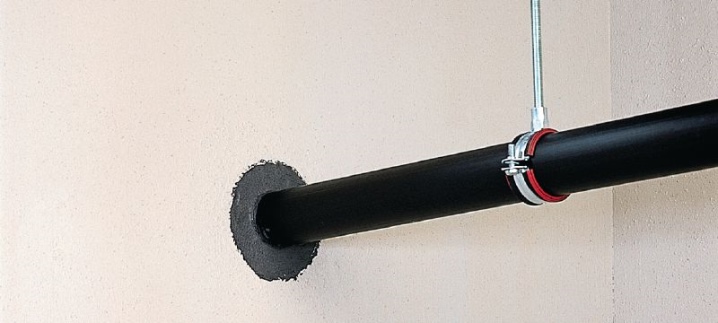

Heat-resistant mastic can be used to cover heating devices from the outside. It is suitable for filling gaps where pipelines are being laid.

Applications

As already noted, fire-fighting mastic can be used in a wide variety of areas, but the main field of application is to ensure the fire safety of facilities.

Thermomastics is suitable for insulating metal structures from the effects of open fire. It should be applied to supporting structures, air ducts and pipes. The importance of a fire-prevention coating is determined by the fact that metal products soften from heat, respectively, the level of their strength decreases.

The surface is deformed after 10-15 minutes of intense heat exposure, and in the presence of a mastic coating, this figure increases to 2-2.5 hours.

Also, mastic is used when working with cables. With its help, all kinds of holes and slots are sealed. The outer layer of the product is reliably protected, while the outer winding also becomes non-combustible. When laying cable lines, it is recommended to use compounds based on acrylic.

Mastic is also widely used in the process of construction work. It is used to seal openings, cracks and fittings. Especially popular is the MTO thermo-expanding mastic, which is designed for sealing joints and sealing cable laying areas.

Due to the binding components of the mastic, old roofs can be treated. The surfaces will be firmly adhered. It is relevant for fire protection of concrete structures and bitumen, relieves stress and thermal stress.

Fire-fighting mastic is often used for wood products. Not only is it able to limit the effects of fire, but it can also prevent rotting. A some of the compositions act as biosecurity, thanks to special components.

Selection Tips

Experts note that choosing the right mastic is not as difficult as it seems at first. The product in a huge assortment is presented on the shelves of specialized stores. Specialists will help you to make the right choice. However, some recommendations in this direction are still present.

So, with regard to the selection criteria, the main indicator is the working temperature of the composition. If the work is planned to be carried out from the front side, it is better to dwell on the heat-resistant version. You do not need to buy a large amount of mastic, as this is an extra financial cost. To calculate the amount, it is worth carefully measuring the area of \ u200b \ u200bworking areas.

The financial issue is one of the fundamental ones. Focusing on the price and trying to save money, someone can pick up a cheaper type of mastic than the one that is needed in a particular case. And this, in turn, can lead to sad consequences. Wherein experts believe that foreign and domestic products differ significantly in price, but the difference in compositions and characteristics is minimal.

As for the recommendations for choosing, experts believe that the use of heat-resistant mastic will be relevant in any case. However, it has the highest cost, respectively, in order to save money, you can use simpler varieties.

Terms of use

If the work was performed correctly and the application technology was fully followed, the product's service life becomes quite long, amounting to about 5-10 years.

Before using the composition, the treated surface is cleaned. Rust is removed from it, solvent treatment is carried out. The coating is applied with a spatula or using special equipment. It is perfect as a ground layer, the first of which should be 1 mm, and the next 1.5 mm.

Work is carried out at positive temperatures, preferably in good weather. The drying process should be checked. This can be done both visually and tactilely.

It is impractical to apply mastic in less than 3 layers. The minimum thickness of the fire protection layer is 3 mm.

You should also carefully read the instructions for use. It contains the main points that will be useful when carrying out work.

The comment was sent successfully.