All about polyurethane mastic

The thermal insulation properties of any building depend on the integrity of the building. But no matter how new the building is, over time, weather conditions, loads and other factors will do their job, and under their influence, cracks will begin to appear in the walls, on the floor and on the ceiling. It is through the cracks in the house that moisture, condensation and cold begin to accumulate in large quantities. All this leads to a decrease in the thermal insulation properties of the structure.

But there is a material with which you can seal seams, cracks and joints. We are talking about polyurethane mastic. In this article we will tell you everything about this building material, about the features, types, areas of application and rules for applying to the damaged area.

Peculiarities

Polyurethane mastic is one of the types of plastic substances that can be used to waterproof absolutely any surface. This building material is now quite widely and often used.

The demand for polyurethane mastic is determined by a number of features and advantages that are inherent in it:

- quality;

- reliability;

- long service life and storage - shelf life is about 15 years;

- excellent physical and mechanical properties;

- made from safe and environmentally friendly products - such a composition guarantees safety for both humans and the environment;

- wide assortment - in the modern construction market there is a large selection of mastics from different manufacturers;

- scope of application - the substance is suitable for waterproofing various types of surfaces, both during construction and in the process of performing repair work.

It is also worth noting that absolutely all polyurethane mastic is made in accordance with the requirements of regulatory documents and must have a quality certificate.

The condition of the coating on which the polyurethane mastic is applied is significantly improved. It forms a membrane film on the surface, which prevents moisture, direct sunlight from entering the base material. The heat resistance of such a surface increases to 150 ° C.

Views

Polyurethane mastic, which is presented on the consumer market today, is of two types.

One-component

It is a liquid substance, the main element of which is a pure elastic water-repellent polyurethane resin. It can be used as the main material for waterproofing in any type of work - both internal and external.

The use of one-component mastic for waterproofing swimming pools is strongly discouraged, since constant contact with chlorinated water reduces the properties of the material.

Two-component

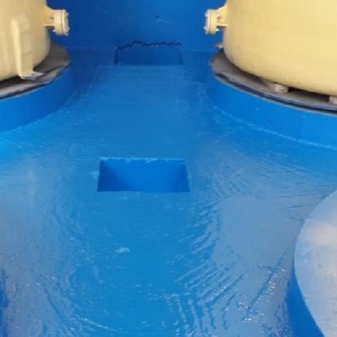

This type consists of two components - resin and binder. Such mastic, as well as one-component, can be used for waterproofing roofs and floor coverings. And on top of that, this particular species is suitable for the treatment and corrosion protection of drinking water tanks.

As for the limitations, it is not recommended to process fragile bases and pools with this type of mastic.

Earlier in the article, it was already said that the scope of application of polyurethane mastic is currently very wide. Depending on the type of substance, it can be used to create a waterproofing layer:

- on the roof covering;

- on the foundation of the building;

- in the pool (you need to choose the mastic on which the manufacturer indicates that the material can come into contact with chlorinated water);

- on the screed, tiles.

- in the parking lot, garage.

Very often, polyurethane mastic is used during repair work. The substance is completely coated on walls, floors and other surfaces prior to application of the base material.

The product is very easy to use, so it will not be difficult for either a professional or an amateur repairman to apply it.

Application rules

Polyurethane waterproofing mastic, like any other building material, must be used correctly and applied as required. There are several basic rules for applying mastic:

- the surface on which the substance is applied must be pre-prepared;

- the mastic itself must be mixed correctly;

- application of the material is possible only at an air temperature of 5 ° C to 35 ° C - if the temperature regime is not observed, the time of complete drying of the material will change.

As for the preparation of the base, then this stage of creating a waterproofing layer must be approached very responsibly. The final result depends on the preparation and condition of the coating.

So, when applying polyurethane mastic to a metal surface, it is necessary to thoroughly clean the latter from dirt, rust and corrosion, smooth out all irregularities and roughness. Then the surface should dry. Next, using a primer, the metal surface is primed. Drying time of the primer is 24 hours.

Only after completing all the steps can you start applying the mastic.

If the base on which the waterproofing material is applied is concrete, it must also be thoroughly cleaned of dirt and leveled. The concrete must be completely dry. Dryness can be checked using a special device - an aerator. The surface is also primed.

For other types of surfaces, such as roofing felt or polyurethane, the preparation steps are almost the same.

A few more subtleties of applying the mastic itself:

- the thickness of the first layer is no more than 1 mm, the material must be applied with a special roller or brush;

- geotextile, reinforcing material is laid on the mastic layer;

- during the day, the first layer must dry;

- then a second layer is applied, the thickness of which should also be 1 mm.

For in order to avoid mistakes when applying waterproofing material, you need to carefully read what the manufacturer writes on the packaging, that is, study the instructions. In the work, it is necessary to take into account all the recommendations and rules of operation.

The comment was sent successfully.