Selection and use of face shields

With the development of industry in various sectors, the need arose not only for qualified personnel at enterprises, but also for overalls that would protect against accidents and dangerous situations. In factories, chemical and other industries, in addition to specialized clothing, there is a need to use protective face shields, which allow you to protect the face, and in some cases the frontal and neck areas from sharp fragments, hot splashes and chemical elements. In order to fully protect yourself in the workplace or during difficult and hazardous work, it is important to know how to choose the right face shields.

Peculiarities

The face shield can be used to protect the face while performing professional or specific activities. Its use is essential in the following industries:

- construction;

- gas and oil industry;

- ferrous and non-ferrous metallurgy;

- chemical industry;

- mechanical engineering.

It is customary to protect the face during painting, when plastering surfaces, during welding and other repair work. Workers who come into contact with blast furnaces or steel furnaces must also wear these protective equipment.

In order for the use of protective shields to be safe and convenient, special standards of GOST - 12.4.023-84 have been developed. SSBT.

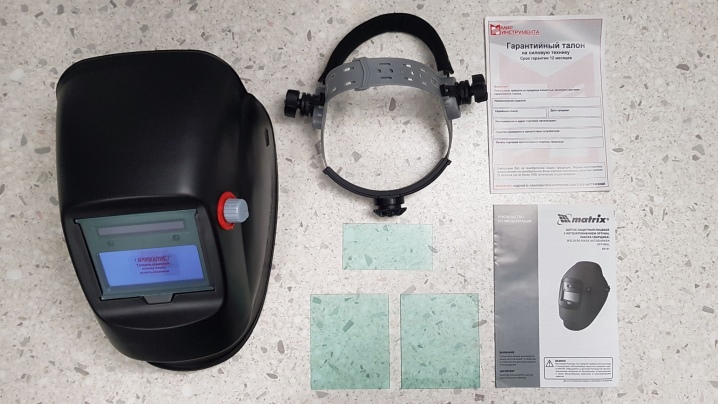

The design of such products should be as simple as possible, but at the same time reliable. The face shield consists of:

- body that protects the face;

- frontal protective tape and parietal tape, which allow you to securely fix the product on the head.

For a variety of jobs, modified products are used, in which there is a visor that can protect the forehead of the worker. This element is attached to a helmet or frontal tape. In addition, the shields can be equipped with forced ventilation, a light filter, a movable glass holder, a handle and an elongated screen for more complete face and neck protection.

The housing material can be varied to suit your specific application. Denser materials are needed for work where contact with solid particles can occur. Versatile products are suitable for protection against radiation, splash of chemicals and molten metal, and sparks. In addition, there are also welding shields, which have a special light filter that protects the eyes of the worker.

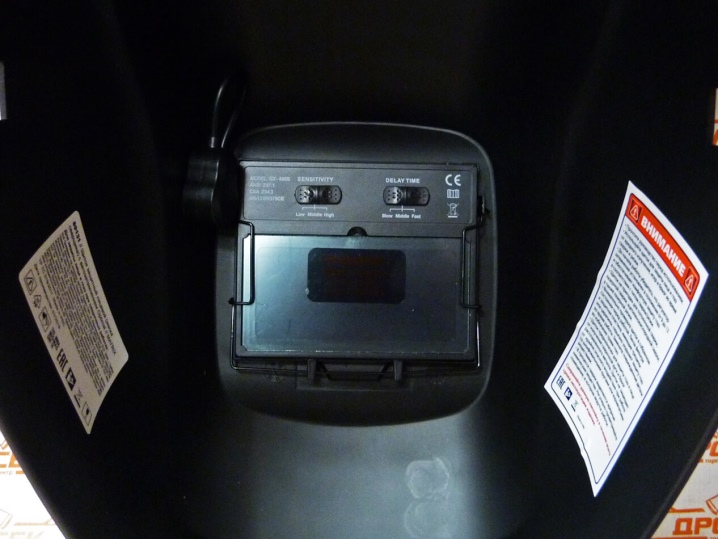

Modern modifications allow you to adjust the degree of shade for different welding conditions.

Views

Since face shields are in demand and are a prerequisite for certain work, you should dwell in more detail on the varieties of these products. Among the most important options, it is worth highlighting such shields as:

- protective products of a universal type with a transparent shield;

- shields with special attachments attached to the helmet;

- products for welding, which are attached to the helmet;

- protective shields for electric welders.

A versatile variety suitable for a wide variety of jobs where workers may encounter fines, splashes and chemicals. There are various options for products with different degrees of protection, which is determined by the glass material.This option is easy to use, because representatives of different professions prefer to wear it to protect the face area. Thanks to the elongated design and rounded shape, the face, neck and upper chest are protected, and the worker can freely turn and lower his head while working.

Protective shields, which are attached to the helmet, are considered more comfortable and safe, as they protect, in addition to the face, also the worker's head.

Professionals prefer to work in closed-type one-piece products. These options are especially relevant for welders, as they allow them to provide the highest level of protection. Thanks to the light filters and the possibility of their adjustment, the worker can create the most favorable conditions for himself, under which he will see well the adhesion site, while not harming his eyes. Another advantage of welding shields can be considered the presence of a large viewing area, which makes it possible to correctly assess the work and avoid emergency situations.

The protective face shield for the electric welder differs from other options in its design and materials. Unlike a universal product with a simple headband or with a helmet attachment, this version is a one-piece design with a head section that protects the forehead and top of the head, as well as a rounding in the chin and neck area, which prevents sparks from hitting the skin. Products with a light filter are used for both conventional and electric welding, protecting the eyes from the negative effects of bright flashes of light.

Another type of protective equipment is a mesh shield. It is used for activities involving mechanical work, in which solid particles can fly into the face.

The product is made of steel and has a small cross-section, which does not allow small parts to pass through, but conducts air well. To protect the shield, its mesh is painted with nitro paints, which prevent corrosion. The body of such shields is made of durable plastic, the headband has a smooth adjustment function and reliable fixation, and for ease of use, a soft insert is provided on the forehead.

Materials (edit)

Due to their special purpose, the shields are made exclusively of wear-resistant materials that can withstand mechanical damage, shock loads and other types of wear. Among the materials from which these products are created, polycarbonate can be distinguished, which, in addition to impact resistance, copes with short-term exposure to high temperatures.

Another material for the manufacture of protective products is heat-resistant plastic. Thanks to this material, a worker in contact with an open fire or working at high temperatures feels half the heat, since half is taken up by the material of the protective shield. In addition to this advantage, heat-resistant plastic copes with mechanical stress, as it has good impact resistance.

The most common material in low-cost models of protective shields is plexiglass or PMMA.

These products are similar in composition to heat-resistant plastic, but they contain additional components that effectively resist chemical compounds. Thanks to polymers, it became possible to create hypoallergenic materials that are suitable even for allergy sufferers.

Any of the above materials have high dielectricity values, so they can be used to work with electrical appliances. Modern shin guards are lightweight, which reduces stress on the neck and spine, providing the most comfortable working conditions. The advantage of the shields is also a completely transparent screen glass that does not have any distortions, which makes it possible to use protective products for a long time.

How to choose?

In order to select high quality and reliable face shields, you need to pay attention to the following factors:

- the ability to adjust the headbands;

- high impact resistance of basic materials;

- the material from which the protective screen is made;

- the weight of the entire structure;

- additional accessories.

When choosing a protective device for your head, you should decide on the type of attachment. If there is no danger of head injury, then you should opt for eye protection products, which are attached with tapes directly to the head. It is important that the bands are smoothly adjusted and securely fixed in the chosen position. If face shields are not enough, it is better to purchase products that are attached to a helmet in order to fully protect the entire head during work. Such shields are especially popular for protection against an electric arc.

The choice of products with certain indicators of shock resistance and protection against various phenomena should be made based on the type of occupation.

For long-term use of protective shields, the weight of the structure is of fundamental importance: the lighter it is, the more convenient it will be to work in it. For an electrician who constantly uses protective equipment, this is of particular importance. Locksmith's shields differ from others in a one-piece design, they have a small plastic helmet and a semicircular transparent shield. When choosing such products, it is important to pay attention to the convenience of the protective structure, its weight and the ability to quickly change the shield if the need arises.

Storage and operation

The shelf life of face shields varies depending on the manufacturer and operating conditions. To maximize the "performance" of protective equipment, it is worth purchasing special covers for them. If you do not use additional means, it is necessary to store the shields away from hard and sharp objects that can damage the integrity of the protective shield. Any scratches make it much more difficult to use the products, leading to eye fatigue and later other health problems.

On each product, the manufacturer indicates the terms and principles of storage of protective equipment.

Besides, the manual contains information on the rules of operation and maintenance of the shields. If you follow the instructions carefully, you can use a protective device for a long time, protecting your face from any negative factors. If the instructions from the manual for the protective shield are disregarded, its validity and properties can be significantly changed for the worse.

See below for which face shield to choose.

The comment was sent successfully.