What should be the hood for the barbecue?

Brazier is a necessary thing in a private household. This useful tool comes in a variety of sizes. For large, stationary devices that are used in gazebos or other rooms, a good exhaust hood is required.

Peculiarities

Braziers can be portable and stationary. The mobile option is a simple design that you can assemble yourself. A hood is not required for such a device.

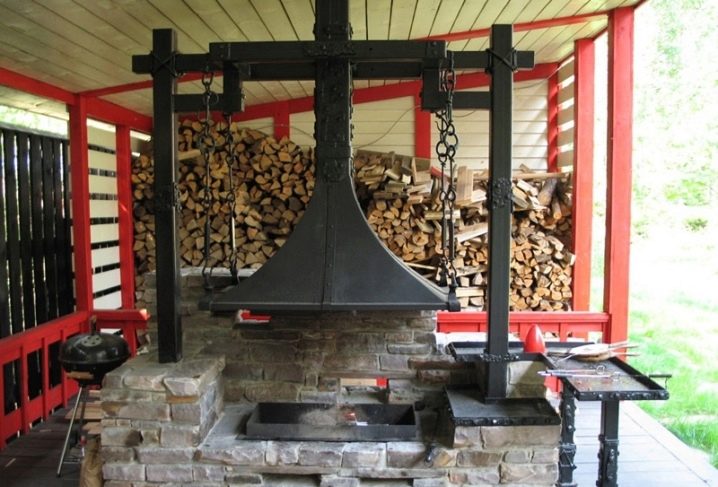

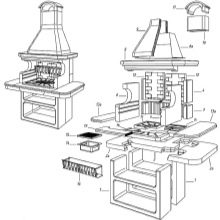

A stationary barbecue is a more monumental structure that occupies a large volume in the room.

A similar unit is designed to prepare meals for a large number of people. Much more fuel is needed for its normal functioning. Without a good hood, such a structure will not work effectively.

At first glance, there is nothing complicated in such devices. However, there are nuances to be aware of. A large grill should have good ventilation, which would allow the removal of combustion products. Such devices, including barbecues, are often sold with ready-made hoods.

Views

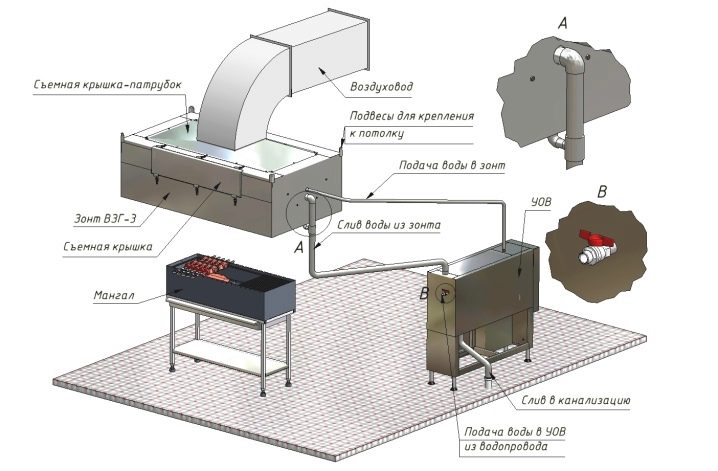

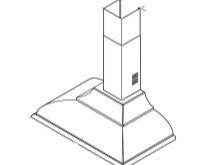

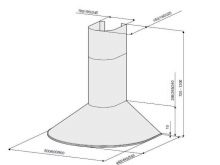

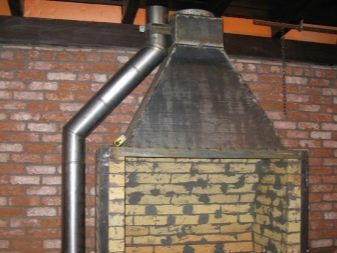

The device itself is made on the principle of an exhaust hood; is a small dome in the form of a hemisphere, cut pyramid or parallelepiped. Often, such hoods are decorated and become an integral part of the overall interior. They look natural and organic.

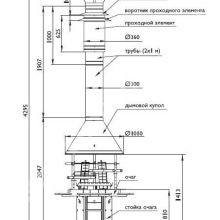

A prerequisite: the area of the dome must exceed the area of the equipment itself by 30 percent. Only in this case it will be possible to efficiently collect and remove combustion products. A prerequisite is also the presence of a tall pipe and a fan.

Equally important characteristics:

- The chimney necessarily has a narrowing and bending, which will generate good draft. The optimum distance between the ground and the top point of the pipe is at least 2.8 meters. The higher the pipe, the better the thrust will be.

- A heat-resistant spark arrestor is placed on top of the pipe. By design, it is similar to a sieve through which smoke passes freely.

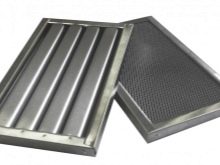

- It is necessary to supply a grease trap in the form of a frame with a removable container. The fat that comes out of hot meat accumulates in it. Such a container is periodically changed or cleaned, depending on the design.

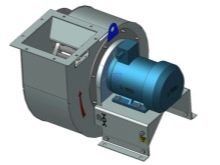

- A smoke exhauster must be present - a fan that creates additional air exchange and increases the removal of smoke.

All of the above points are simple in their design.

It is important that they fit properly.

In specialized stores, ready-made metal "umbrellas" are sold, on which there is a duct smoke collector. They can be fitted to homemade equipment.

Often the hood in large barbecues is supplied with a fan.as well as a forced blower providing additional traction. The device itself has standard parameters and is not something technically difficult. If the equipment is non-standard, then it can be ordered from a specialized organization. For example, there are companies that manufacture hoods even with complex pipe bends or open structures.

Individual orders with additional options can be quite expensive. In order not to spend too much, you can do everything you need yourself.

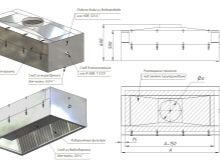

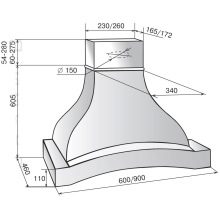

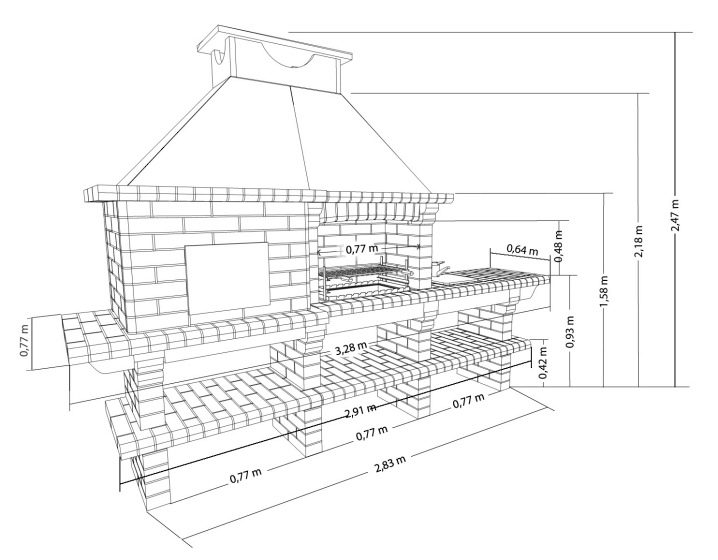

Standard parameters of a four-slope hood for a wood-fired barbecue:

- metal that is suitable for such products has a thickness of 1 to 3 mm;

- smoke box length 855-1550 mm;

- width - 660-950 m;

- pipe with a height of at least 3 meters;

- pipe section from 255 mm.

Sizes can vary markedly. However, it is important to keep the proportions unchanged.

How to make it yourself?

A metal hood has the following advantages:

- light weight;

- it is possible to install additional options;

- low price;

- simplicity of design;

- ease of installation.

Brickwork has an undeniable advantage: such a structure can stand for a thousand years without visible damage.

It will only be important to clean such an object from soot in time.

After all, it has a detrimental effect on the quality of the prepared dishes and the operation of the air duct itself. Traction will sooner or later decrease due to accumulated dirt, so it is best to do a preventive cleaning.

It is important to decide at the very beginning which type of exhaust device is preferable.

The materials required to create a metal hood are simple:

- iron sheets 1-3 mm;

- corners with a section of 30 x 30 x 30 mm;

- bolts;

- thermo primer.

The height of the umbrella can reach 2 meters, the optimal size of the barbecue is 110 x 65 cm. The umbrella is composed of three units: base, dome with internal fastening and pipes.

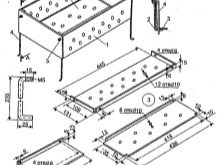

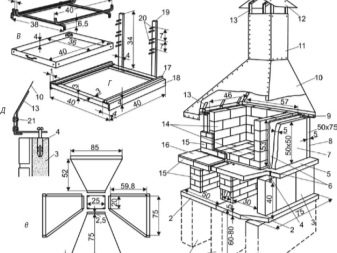

It is not difficult to make a cooker hood with your own hands. First, markings are made on a sheet of metal with a marker, which corresponds to previously drawn sketches. Then, with the help of a grinder, the necessary components are cut out, the parts are assembled and the joints are welded.

A brick hood has its own characteristics. It is made of special bricks (fireclay) mixed with clay and sand. The clay must be of a certain grade and soaked in water for 48 hours. A special frame is made in a brick hood, on which a brick is placed. In this case, the material must be treated with special refractory enamel.

The frame is fixed with brazier fittings on anchor bolts or by welding.

This is followed by the laying of bricks. The base, that is, the first is glad, is laid with the jogging side of the brick, the shortest. A conventional smoke box consists of 9-11 rows. The masonry is made in such a way that it narrows, that is, the displacement occurs about 16 mm at each level, along the end part of 35 mm. Then a square-shaped pipe is laid out of brick.

At the top, the pipe has a cross section of 265-265 mm. This figure was obtained empirically, it is optimal for the operation of the retractor, while the height of the pipe is about 3 meters.

It is important to withstand at least 3-4 weeks after the end of the masonry, so that the structure has settled for greater strength. It is impossible to rush to use the "raw" structure. This can lead to deformation and cracking of the material.

The surface is covered with a special primer, which will protect against high temperatures. As you can see, from a technological point of view, there is nothing super complicated in such works; a person with minimal construction skills can make the masonry.

Before starting to work, the corners should be thoroughly cleaned, then cut with a grinder the required amount.

Always wear protective goggles and gloves when working.

Choice of materials

It is recommended to mount a metal hood strictly in the center so that it hangs over the equipment. The pipe is closed with a visor to protect it from moisture ingress. The material commonly used is copper or stainless steel, which are the best to resist corrosion. Such materials can be used for a long period of time.

A metal hood is the most acceptable option, it is relatively inexpensive and has excellent performance.

For the hood, red or fireclay bricks are also used, which have no less good technical indicators.The mortar used for masonry is made in proportions of 1: 3, where 1 is cement of a grade of at least 400, and 3 shares are seeded sand.

Components

Components for creating a hood for a large barbecue are required as follows:

- pipe;

- spark arrester;

- grease trap;

- fan with motor.

All components are collected from different sources. A mangal fan can be purchased at a store, a spark arrester and a grease trap are easy to make from a metal sheet. The most important element is the pipe, which must correspond to the working capacity of the device. If the cross-section is too small, then the combustion products will enter the room, which is highly undesirable. Before creating the hood, you need to make a detailed drawing and carry out careful calculations.

Construction of drawings

A correctly drawn up drawing is a guarantee of flawless operation of the device for many years. The cross-section of the pipe and the weight of the barbecue are the main parameters that must be taken into account when working out the schematic plan. You should start building a drawing with a sketch and drawing the base dimensions of the barbecue. Based on these figures, it will be possible to further calculate and draw the hood. A correctly drawn up drawing will also allow you to calculate the amount of material required. Avoid overspending.

Assembly instructions

- The dome is assembled first. Then the pipe is assembled and fixed.

- After the end of welding, the seams are processed with a grinder. The finished surface is coated with a fire-fighting anti-corrosion primer.

- Then you should mark the metal that will go to the sheathing of the exhaust hood. Sheets are bent at the corner of the workbench. The metal is attached to the base with rivets and bolts;

- It is recommended to place a metal plate (size 98 x 35 cm) in the canopy diagonally to improve traction. The indent from the edge should be about 1.5 cm, for these edges the plate will be attached.

- The base is mounted on the grill with anchors or special screws. After that, the dome is installed and the pipe is fixed with rivets.

The pipe can also be made of brick, but in this case it will weigh much more.

A massive solid foundation is required under it so that deformation or distortions do not arise during the operation. Exhaust hoods made of bricks are created according to a simple principle: a metal frame is cooked, which is lined with refractory material.

Often, the hood can be decorated with a wild stone. The metal umbrella can also be sheathed with wood panels; there must be a thermal spacer between the panels and the metal.

Where can you apply?

The hood can be used in any room:

- on the balcony;

- in a glazed gazebo;

- garage;

- hall of the restaurant of oriental cuisine.

If everything is done correctly, the hood will work smoothly in closed rooms for a long time.

Useful Tips

It is recommended to make the chimney cross-section optimal; how the chimney will work by 80% depends on the diameter of the chimney. The metal structure must have a cross section of at least 16 cm. The brick chimney must have a cross section of at least 26 cm.

The length of the chimney is the key to good draft. The structure must be sufficiently elongated, otherwise smoke will enter the room. When creating a barbecue and a hood, it should be remembered that the material must correspond to the temperatures at which the process takes place. Otherwise, too thin metal will deform. You can not also use asbestos in construction, this material is manufacturable, but unsafe for health.

See below for more details.

The comment was sent successfully.