Making barbecue from fittings

If you decide to go to barbecue, then you should take care of the grill in advance. Such designs can be purchased in specialized stores, but a homemade brazier will be the simplest and most budgetary option. Today we will talk about how to make this product from fittings with our own hands.

Projects

There are many options for creating this design for cooking kebabs. Of all the characteristics of such braziers, only the height of the side parts is constant. As a rule, it is in the range of 13-15 centimeters.

If you make the sides smaller, then the coals that are placed close will begin to burn the meat, and if you raise them higher, you will need too many coals for sufficient roasting.

All other dimensional parameters can be selected independently, depending on several factors. The width will depend on the length of the skewers used. The length of the structure is determined by the number of skewers. The height of the legs can be almost any. As a rule, the shortest supports are found in compact portable barbecues (25-30 centimeters).

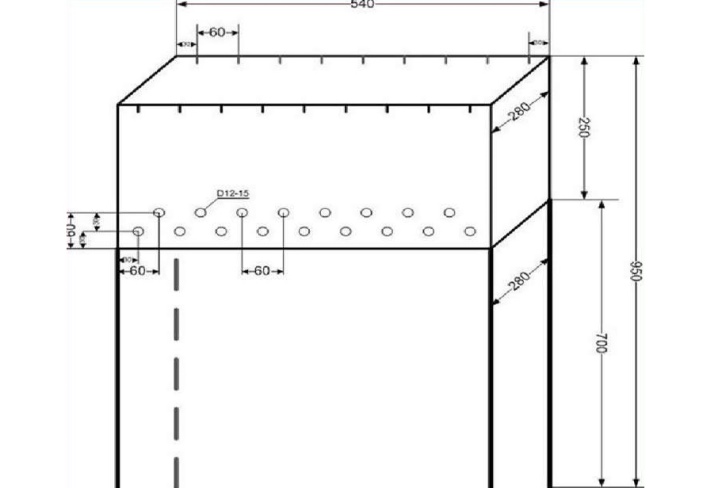

Projects and drawings also reflect the thickness of the metal used for fabrication. If you plan to weld a structure, then preference should be given to bases with a diameter of 10-15 millimeters. If it is a prefabricated product, then thinner specimens will do. It is better to immediately reflect all dimensions in the drawing so as not to get confused in the manufacture of the structure. You can also sketch out each individual detail on paper.

The armature is a fairly durable and wear-resistant material, so structures made from it will not collapse and deform. It is also considered fire resistant, so it can withstand even the highest temperatures and the effects of fire. At the same time, the reinforcement has a relatively low cost.

Braziers can also be made from old unnecessary leftovers.

What is required?

In order to build a homemade brazier, you will need the following materials and tools.

- metal reinforcement with a thickness of 12, as well as 10 millimeters (to create legs);

- welding equipment;

How to do it?

To begin with, do face-to-face marking on the material. To do this, you can use a regular ruler. According to the project, all dimensional values of individual elements of the barbecue are transferred to a metal base. In the finished form, the product should have a conical shape, with the tip pointing down.

In advance, you should make two rings from the reinforcement.

One will hold the side pieces together at the top and the other at the bottom. Next, the reinforcement is cut into separate segments. For a compact mobile barbecue, parts of 25-30 centimeters are quite enough.

Moreover, they must all be the same in length.

When all parts are prepared, you can start welding. All metal pieces are carefully welded to the two rings. The result should be a truncated cone structure. The side pieces must be evenly spaced among themselves. After the metal base is ready, you can start making the legs.

The supports are required to keep the brazier in an upright position, while the lower part of the product should be removed 8-10 centimeters from the ground. Supports should be attached to the narrower part of such a homemade barbecue. The wide part serves as a place for fuel supply.

For a secure fit, only three parts will be enough. It is recommended to additionally strengthen them with iron struts, which are also made of reinforcement. A metal sheet will need to be laid under the bottom of the structure made. As for the thickness of the sheet material, a metal of 2 millimeters may well be suitable for prefabricated structures, but for the bottom it is still better to take a three-millimeter metal base.

In order for the metal sheet to hold firmly, it can be attached to the brazier with a few bolts, but if necessary, such a product will be difficult to disassemble.

For the manufacture of a barbecue from fittings, see the video.

The comment was sent successfully.