All about three-piece aluminum ladders

Aluminum three-section ladders are the most popular type of lifting device. They are made of aluminum alloy - a durable and lightweight material. In the construction business and private households, three-section stairs are most in demand, without them it is almost impossible to carry out repair, installation and finishing work.

Purpose and design features

The purpose of an aluminum three-section staircase can be different, it all depends on the specifics of the work being done. When it is necessary to change the light bulb, for example, in the front door, then a ladder should be used for this. The lighting device is mounted on the wall. Sometimes it is necessary to replace the ceiling in the workshop (it is located far from any walls), for this you need to climb under the ceiling, to a height of more than four meters. In this case, a stepladder is required. There are several types of stairs in total:

- one-section;

- two-section;

- three-section.

The latest devices are most in demand in a wide variety of areas of economic activity. The three-section ladder can be used for the installation of drywall, cornices, and also carry out painting work at rather large heights with its help.

When buying a device, it is important to imagine what needs it will be designed for. Modern lifting devices are thoughtful and robust and can be easily operated by one person. Ladders are easy to store and take up a minimum of space.

The number of steps can be different. It is important to note: there are universal ladders that can be easily modified, becoming stepladders or attached structures in a matter of seconds. Such devices have their advantages: the same lifting mechanism can be used in a wide variety of work activities, which allows you not to spend money on the purchase of additional equipment. Areas of the most frequent use of three-section devices:

- repair of houses, apartments and offices;

- pruning plants;

- as an attic lifting device;

- picking ripe cherries, apples, pears, etc .;

- installation of wiring;

- use in a warehouse;

- utilities also use them frequently.

Advantages and disadvantages

Advantages of a three-section staircase:

- has a low weight;

- easy to disassemble and assemble;

- compact, easy to transport;

- there are universal models that can replace several types at once;

- is inexpensive;

- not affected by corrosion.

Among the shortcomings, it should be mentioned that the ladder consists of three, which a priori reduces the strength factor. The joints can loosen over time. Backlash appears first, then deformation. Before starting work, it is imperative to check how tightly the nodes are adjacent to each other. You should pay attention to the performance characteristics prescribed in the instructions.

For example, the stairs must not be overloaded. Typically, three-section lifting devices withstand a weight of about 240 kilograms.

There are three types of fastening for modular elements:

- the module is installed in the module - in this case, all nodes are fixed with pipes that are inserted into each other;

- widespread fastening "threaded rod" - in this case, the elements are fastened with a hairpin or bolt;

- a clamp on a clamp is often used - when the nodes are bolted together.

The latter type is considered the most effective, for the price of such stairs are more expensive than other analogues.

Varieties

In total, there are several types of three-section stairs:

- three-knee sliding ladder;

- lifting structures that slide out;

- folding ladders;

- attached sliding structures;

- knee ladders;

- folding universal ladders with hooks;

- reinforced professional ladders in 3 or more sections.

The ladder, which has three sections, is, in fact, an improved model of the stepladder, to which one more link has been added. With the help of this element, you can transform the structure depending on the kind of work that needs to be done. Lifting devices like these are preferred by many homeowners: they are compact, easy to move and store.

Additional advantages:

- if you fold the lower block, then the upper part will become a "house", which will consist of two sections;

- the lower sections allow you to make a stepladder, in which there will be four supporting elements;

- by expanding all the blocks, you can make a staircase that will be about ten meters long;

- if the third element is dismantled, then the ladder can be made attached.

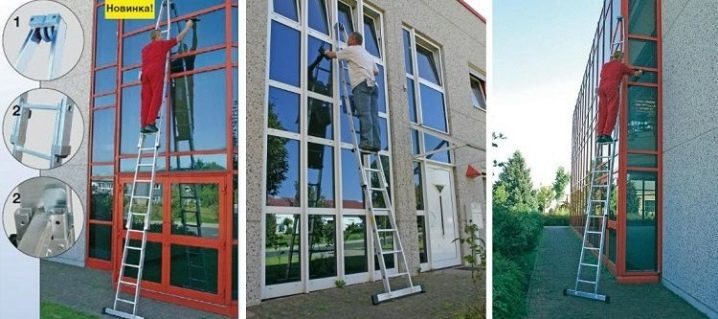

Ladders are in demand in the construction business, the sections of which are attached using special cables. Such a product can reach a height of 10 meters or more. Also, when building houses, a three-section retractable ladder is often used. Private homeowners also often use similar products: they make it possible to repair the walls under the roof of a two-story house. The height is adjusted using fixing steel cables, the pull-out elements are fixed with special hooks.

Firefighters three-section ladders are often also in demand: they are quickly assembled and assembled, make it possible to climb to a fairly large height.

It is important to distinguish between a three-knee design and a three-march design. The first type is used in the professional activities of firefighters, public utilities, employees of the Ministry of Emergency Situations and builders. The disadvantage of such ladders is that they require two workers to mount them.

Ladder

A stepladder is a ladder that has a platform-support in the kit. The structure can perform a wide variety of tasks at different heights:

- three-section lifting device;

- a ladder that can be a platform.

Stepladders are simple and reliable in operation. When folded, such structures are compact, they are easy to transport on the roof of a car and even in the trunk. When storing ladders, they take up a minimum of space. Stepladders are mainly made of aluminum profiles. But there are also options from other materials:

- steel;

- wood;

- PVC.

Two sections of the ladder are interconnected by fasteners, fixed with a chain or a metal cable. The tips are necessarily equipped with damper rubber mountings: this makes it possible for the structure not to slip on a smooth floor.

Attached

Ladders are useful in everyday life. The largest devices can reach a height of 5-6 meters, they are used most often in the workshops of large enterprises. Three-section ladders can reach a height of 3.5 meters (this is the minimum value), or they can be superimposed (14 steps), reaching a point that is 11.5 meters above the ground. It is impossible to work in the construction business without such ladders. Attached structures are also used in the following cases:

- repair work with wiring;

- trimming the tops of trees;

- harvesting the fruits of the new harvest;

- storage facilities.

Stairs where the number of steps does not exceed ten are in great demand. Such structures are easy to fold, they are assembled with a height of 1.90 meters.

Hybrid

The hybrid shape of the ladder has the same robust stability as a stepladder, it can be as tall as an extension ladder. A similar structure consists of two elements, like a stepladder.There is a third element that slides up and is fixed at a certain level. Thus, when it is necessary to make a transformation, the ladder can be turned into a ladder of great height in a few seconds.

With platform

The staircase with the platform is small, however, the platform is quite enough to accommodate one person at the top with the tool. The platform gives more stability, it is much more comfortable to work on it. The platform itself has hooks that securely fix it to the supporting elements. To better hold the ladder, use spacers or special lance tips. These braces are essential when working outside the home.

The compactness of the ladder allows it to be easily carried by one worker.

A ladder with a platform requires careful attention to itself: before climbing to the very top, you should test the stability of the structure.

Rating of the best models

Three-section ladders are considered the most reliable; there are several dozen types and subspecies of these structures. The most demanded are the staircases of the company "Efel" (France). Two sections in such models are fastened with extra strong belts, an additional (third) segment can be pulled out, it can also be removed and used as a ladder. Efel focuses on the safety and strength of structures. For example, the steps of Efel products are folded directly into the guides, they are also covered with special notches and have rubber pads.

The ladder is well fixed by special snap locks and safety belts made of extra strong material. The material from which the French 3-section ladders are made is anodized aluminum alloy. This metal has a special protective coating that prevents the material from being modified by oxygen and moisture. Also, dark marks do not remain on the hands, which usually happens when in contact with ordinary aluminum.

The company "Krause" is also characterized by high-quality three-section staircases. In the instruction-memo there is always a drawing of the product, where all important parameters are indicated in detail:

- maximum permissible load;

- how to mount the product;

- how to assemble and mount the constituent elements of the structure;

- how the height stabilizer works;

- how to properly install the upper platform.

The following companies are also known and famous for the quality of their products:

- "Granite";

- "TTX";

- Vira;

- "LRTP";

- KRW;

- Krosper;

- Sibrtech;

- Svelt;

- DWG.

It is also important to understand the marking, which is directly related to the number of sections. For example, 538 is a three-section staircase with 8 steps in each block.

How to choose?

To choose the right three-section ladder, you should be guided by some criteria. You should not pay attention to a product that has a presentable appearance - you should proceed from what kind of "work" the product will perform.

You should analyze the prices and manufacturers whose products are sold on this trading platform. It should be remembered that the staircase will serve for more than one year, during which time it will be influenced by:

- high humidity;

- high or low temperature;

- mechanical stress.

A high coefficient of structural strength, a material that should not be subject to corrosion - these are the two main indicators that you should focus on when buying a three-section staircase. The third important criterion is the stability of the supporting elements. They must have rubber tips, auxiliary clamps. Before making the final choice, it is best to look at quality analogs on the net, for example, from manufacturers such as Lumet or Krause.

A Russian company from the city of Chekhov "Granite" is also considered a good manufacturer. It is recommended to read reviews of professionals and ordinary users.Another important criterion is the number of steps in the product. That is why it is necessary to understand in advance for what purposes the ladder will be used.

The presence of fixing slings is also important: they prevent the ladder nodes from "dispersed" at the most crucial moment.

Special hook-shaped latches must also be present. They also protect products from spontaneous folding. A professional product can withstand a weight of up to 350 kg, but it is also extremely expensive. A household three-section product can withstand a load of up to 200 kg, which is often quite enough for a variety of jobs. You should pay attention to the quality of the site (if any), it should be made of durable material.

The life and health of the employee depends on the quality of the ladder, therefore, when choosing such a tool, all the nuances should be taken into account - there should be no trifles in this matter.

When purchasing a product in a hardware store after ordering online, you should check all fasteners, make sure that all positions of this ladder are working. Keep in mind: modern staircases can often be transformed into a wide variety of shapes. If there are many fixing nodes, then universal products can be transformed at your discretion. The stability of the newly "invented" forms should be closely monitored. Before working on such a ladder, it should be thoroughly tested.

Dimensions (edit)

Three-section devices are of the following types:

- 3x5;

- 3x6;

- 3x7;

- 3x8;

- 3x9;

- 3x10;

- 3x11;

- 3x12;

- 3x13;

- 3x14.

The first number indicates the number of blocks, the second indicates the number of steps.

Approximate combination of sizes and prices:

- 3x6 - from 3700 rubles;

- 3x9 - from 5800 rubles;

- 3x14 - from 11,400 rubles.

Cost by manufacturer:

- "Alyumet" - from 3,900 rubles;

- "Top" - from 4,100 rubles;

- "Krause" - from 5,900 rubles.

Carrying capacity

Modern aluminum alloys are capable of withstanding significant loads. In terms of strength, they are not inferior to steel and at the same time are not subject to the influence of corrosive processes. The three-section product weighs a little, but at the same time it can withstand a load of up to 245 kg.

Number of steps

By the number of steps, the stairs are subdivided:

- 3 sections with 6 steps;

- 3 sections with 7 steps;

- 3 sections with 8 steps;

- 3 sections with 9 steps;

- 3 sections with 10 steps;

- 3 sections with 11 steps;

- 3 sections with 12 steps;

- 3 sections with 13 steps;

- 3 sections with 14 steps;

- 3 sections with 16 steps.

In total, the device has no more than fourteen steps (the minimum number is six). There are exceptions to the rules, but they are found only in professional types of lifting devices (firefighters, emergency services).

How to operate?

Before starting to work with a three-section ladder, you should read the safety instructions. It is required to keep in mind the following factors:

- are there any special fixing cables;

- are there safety slings;

- the ends of the supporting elements must be equipped with rubber nozzles;

- it is recommended to pay great attention to the locking hooks; their work should be understood in detail;

- household appliances are loaded up to 240 kg, a professional ladder can withstand a load of 1/3 of a ton;

- it is imperative to understand how the site works, what clamps it has (they must be very reliable);

- all additional accessories included in the kit should be studied and understood how they function, what is their purpose;

- it is important to pay attention to the labeling and warranty periods;

- the lifting device must be on a perfectly level surface;

- the plane can be leveled using metal sheets or plywood boards;

- there should be no objects with sharp corners or edges around the lifting device;

- the coefficient of adhesion to the plane must be very high;

- at the beginning of installation, check the fastening of the belts;

- fixing elements should not contain defects: cracks, chips, etc .;

- when working on the highest steps, you should be especially careful;

- you cannot work if your arms or legs are numb, if you have dizziness or high fever;

- it is not recommended to work at height during bad weather;

- there are no safe ladders - the safest thing is to follow the rules of the instruction.

For information on how to properly use three-section aluminum ladders, see the following video.

The comment was sent successfully.