All about band saw sharpening machines

Sawing and turning of wood, as well as other sawn timber, occurs with circular or band saws. However, the use of a band saw is much more technologically advanced. Such varieties allow several times to speed up the work process, as well as leave much less waste after work activities.

A band saw is a working tool for special machines that allows you to cut many materials. But, like other cutting tools, such a saw tends to become dull, which means that for further normal use it is necessary to sharpen the blades.

Peculiarities

A saw of this type is a closed band of teeth. This design has several advantages over other saws.

A band saw is useful in situations where you need to cut some expensive raw material, as the teeth create a neat and narrow cut, thus keeping the maximum amount of material intact. For example, you can use a wood band saw when working with high-value wood materials.

If you sharpen the teeth of such a saw correctly and with constant frequency, then the tool will perform its task efficiently, namely: instantly, accurately and with a small amount of waste, cut parts from almost any material.

What can you sharpen?

A small blade with small teeth can be sharpened with a special file or the usual nozzle of the machine. However, such sharpening is very long and inefficient, and also very often causes a number of saw breakdowns. Given these problems, many craftsmen have long been using an electric sharpening machine that sharpens all the teeth of a band saw quite quickly and equally evenly.

Such machines are divided into several groups.

- Fully automatic centers, they use a specialized feed and sharpening program, such machines are mainly used by large workshops for sharpening or restoring large and massive band saws. The process takes place with the use of cooling chemical liquids and under strict control.

- Semi-manual machines with special tool consoles.

- Small automatic centers, in them the step of moving the web is configured and the process is monitored.

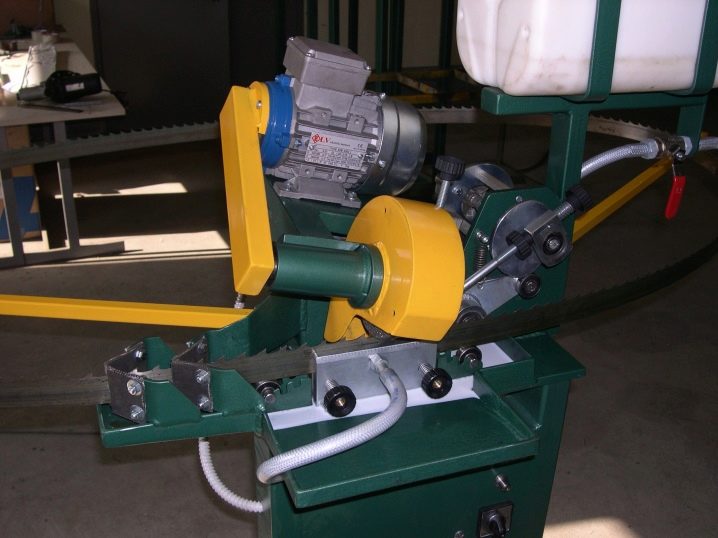

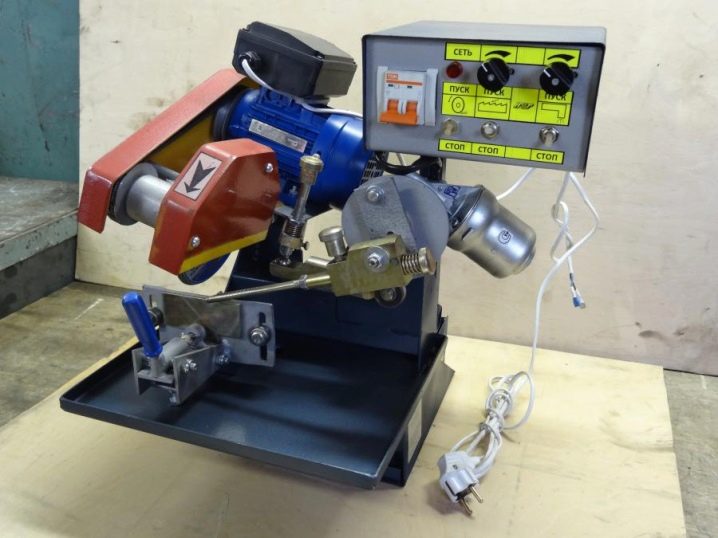

A sharpening machine is an aggregate that helps to sharpen the saw with high quality using a sharpening wheel. Most often, a certain unit is selected for a certain type of saw.

The machine includes:

- base and external structure;

- tool holder;

- special drives used to move the blade and rotate the grinding wheels.

Sharpening process

The undercut is subdivided into 2 types:

- sharpening of edges;

- full-profile sharpening.

The process can be carried out without using a special machine, however, with such a process, you may encounter a number of difficulties. And if with the first type of sharpening such problems will be insignificant, then with the second - you simply cannot do without using a special grinding machine.

The work is carried out using special grinding wheels, each of which has certain parameters, which means that they must be selected individually.

How to choose equipment for sharpening?

It is quite difficult to choose a high-quality sharpening machine, but in the modern market there are more and more truly high-quality tools. With the advent of automatic saw sharpening tools, the quality of the process has also increased, since the human factor in this process is minimized, which means that incorrect angles of inclination of sharpened teeth or knocking down sinuses are excluded.

Among the high-quality machines, models of several brands can be distinguished.

- "Cedar". One of the most widespread and well-known brands. This tool refers to a fully automatic machine tool that uses work due to an installed program. It also implies constant monitoring and use of the coolant for normal operation. "Cedar" is quite easy to use and will suit even novice craftsmen. Setting the angle manually is also not difficult, just loosen the two special bolts located on the back of the tool and adjust the angle you need with the screw near the base. And also the tool has a blade speed regulator.

More modern variations allow the use of diamond sharpening wheels.

- "Taiga"... The brand is no less famous than the previous one, has practically the same characteristics, the control in it is even a little easier. The blade feed angle and speed can also be easily adjusted on the tool.

This machine can be used for both wide and narrow band saws.

- "AZU-02"... The most modified of all the previous machines. All models have a special device for automatic coolant supply. There are several switches on the tool that allow full control over the operation of the sharpening machine. And also in all models, diamond discs are used, which speed up the process of work and improve its quality.

On the AZU-02, it is still possible to adjust the speed modes of movement of the canvas, which also greatly simplifies the process.

- "PZSL 30/60 Profi"... A modern, fully automatic machine with a high sharpening speed. A special cooling oil is used to cool this machine. To work with such a machine, no professionalism is required; in the process of work, only surface control is needed, since the machine turns off by itself when grinding one circle of saw teeth.

- "PZSL 10/2"... Automatic machine for narrow band saws, suitable for both wood and metal saws. This unit, like the previous one, is oil-cooled. The process is fully automated, the task of the master is only to establish the required process and bring the canvas into the machine, then the machine itself will do all the work.

- Astron (A-1)... A full-profile borazon machine, the process of working with such a unit is fully automated. The machine will cut through the entire saw band in 1 full pass. For sharpening, a CBN disc is used, which is of high quality and durability. Setting up the process is very easy and does not require high professionalism.

In the modern market for tools, there is a huge number of a wide variety of sharpening machines for saws, the above are the most basic and popular sharpening machines.

Useful Tips

If you want to sharpen the tool with high quality and ease, then during work you need to observe the following:

- in fully automatic devices, it is necessary to use a special liquid, otherwise the device will overheat and may break;

- an equal layer of material should be removed from each clove during sharpening;

- after work, there should be no irregularities and burrs on the teeth;

- all work must be carried out with the same pressure on the tool and at the same angle;

- the workplace should be cleaned, and nothing should interfere;

- there should always be a first aid kit at hand;

- during work it is necessary to use protective clothing.

When performing work by a person without special education and experience, certain difficulties may arise, therefore it is better to sharpen it with at least some knowledge and skills in this area.

Summing up, we can say that the use of special sharpening machines for band saws greatly simplifies and speeds up the work process, but it is important to follow the instructions and all recommendations, and also not to forget about the safety rules.

For information on how to sharpen a band saw on sharpening machines, see the following video.

The comment was sent successfully.