Features of band saws for wood

Woodworking with a hand saw at one time supplanted cutting with an ax due to its greater efficiency. But progress does not stand still. Now band saws have appeared, which are much more productive than hand-held ones, but before buying them, you need to study their main specifics.

Features and characteristics

It is appropriate to start a conversation about a band saw for wood with a presentation of its differences from manual versions (hacksaws). The external difference is easy to catch, just look at the canvas. Its edge is covered with teeth, which makes it possible to saw both thick logs and untreated timber. Importantly, other types of tools will not allow you to cope with large workpieces. Band saws are divided into home and professional; one of the differences between these groups is the processing speed of the material, but the width of the canvases must also be taken into account.

Device and principle of operation

In addition to the blade, the band saws also include cutting parts installed on top of it. When the gear starts to spin, the workpieces are split into pieces. In narrow saws, the width of the working teeth does not exceed 5 cm. In wide saws, it is at least 3 cm wider. But the geometry of the cutting teeth also plays a significant role.

If the height of these parts is more than 20% in relation to the width of the working area, there is a high risk of blade breakage due to excessive load. Of course, attention should be paid to the accuracy of the tooth alignment. If the gaps separating them from each other are too small, due to the accumulation of sawdust, the tool will fail. In addition to the cutting part and its base, the band saw always has a table for the workpiece to be processed and a special motor. The work surface in homemade constructions is made of thick wood.

A special pulley is used to transfer the power from the motor to the cutting element. It is put on a wheel of a carefully calculated format. The wheel itself must be fixed as carefully as possible. For this, various types of rigid stops are used. The surface of the wheel is beveled slightly, otherwise the tape will slide off.

What is it for?

But before conducting a detailed conversation about the types of band saws and the features of their use, it is necessary to clearly indicate for what purpose they will be used. The general definition of sawing logs does not clarify much. After all, this work can be performed by saws of other varieties. On the other hand, changing blades allows you to increase the functional characteristics of the tool. It becomes possible to use a band saw when processing not only wood, but also plastic, and even metal.

The canvas can be placed both vertically and horizontally. Importantly, such cutting machines can be used even by non-professionals. And not only to apply, but also to obtain a very clean cut line. Additional processing (grinding) is not required. The cut profile changes at your own discretion; the elimination of sparks allows you to work as safely as possible.

What are they?

The main division of band saws includes:

- toothed;

- toothless;

- electrospark formats.

The toothed product is equipped with a closed sawing contour. It allows you to saw and cut through a wide variety of materials. The other two types differ only in the type of teeth. A hand-held (aka portable) band saw can:

- cut down trees in the garden;

- prepare firewood;

- cut wooden blanks to exact dimensions;

- sand wood furniture.

The mini-saw has a pulley with a diameter of no more than 30 cm. The average size group includes products with pulleys from 42 to 50 cm. And heavy sawing units have a drive belt with a diameter of more than 50 cm. Light machines are equipped with motors up to 2000 W. For more powerful devices, drives up to 4000 W are used.

Devices complemented by bimetallic blades can be used to process not only wood, but also metal. The main part of such a canvas is formed by a special spring steel. The working area itself is formed from thoroughly sharpened tool steel. But there is another division of canvases:

- for quenched throughout the volume;

- on those that have not been hardened;

- on flexible blades with strong teeth.

Products with the same hardness as the width are very well compatible with medium diameter pulleys. The harder the teeth, the less blunt they will be. In addition, the permissible speed of rotation of the saw depends on this property. The bench-top belt system, regardless of the strength of the teeth and other parts, has excellent power, it works as reliably as possible. Its important characteristic is the slope of the working surface, which determines the cutting angle of the material.

The orientation of the canvas is another important differentiation criterion. Horizontal and vertical band saws are very different from each other. The vertical format of the fixture can be called with almost every reason a large industrial jigsaw. Despite its small dimensions, such a device is capable of working with thick material. Slicing can be done along the most complex path.

Double-sided saws are usually characterized by increased cutting accuracy. But besides the performance features, other technical parameters must also be taken into account, including the cutting depth. It can reach from 8 to 50 cm. A thin blade can easily break when working with wood that is difficult to process. If you use a very powerful saw, thin bars are often damaged.

Rating of the best models

Examining the technical parameters in general is good, but not enough. It is required to take a close look at the features of specific modifications. Bandsaw is featured consistently in almost all reviews Metabo BAS 261 Precision... Mostly favorable reviews are left about her. High-quality German assembly and first-class materials have resulted in a professional-grade machine that can cut without interruption.

Consumers note that this device does not generate strong vibration. With it, you can make cuts at an angle, in a straight line, according to a complex curly pattern. It is possible to make a radial hole, if necessary. A comfortable pusher is also of great benefit. An induction motor with a power of 0.4 kW was used as a drive, which does not create excessive noise. The safety level of this product is not worse than that of other European products.

In addition to a button to prevent an unscheduled start, there is a blocking of the engine after lifting the cover. The developers have provided an effective illumination of the working area. A typical adapter provides connection to a vacuum cleaner.

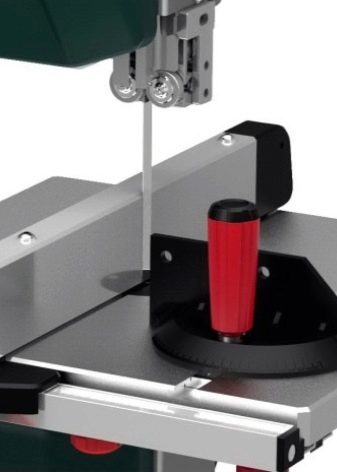

BAS 261 Precision equipped with a cast iron bed and a swivel table. The design allows for a very precise cut, which is very important for many people. No less relevant is the ability to adjust the height of the cut. The tape changes quickly, and without a key. But no one can name any obvious shortcomings of this model. A band saw is also a good alternative.

"Scheppach Basa 1". This device has a long service life. Compared to the just disassembled modification from Metabo, it is noticeably cheaper. The price reduction is achieved by reducing the width and height of the cut. However, its quality is not worse.

"Scheppach Basa 1" great for woodworking and furniture making. The positive properties of this device are its small size and decent power. The band saw is equipped with an asynchronous motor, which does not require any special difficulties in maintenance. The engine is protected at a high level. Reliable fastening of the workpieces is provided by means of rubber clamps, as a result the workpiece does not slip. But it must be remembered that the "Scheppach Basa 1" is not equipped with corner stops.

As for the Swiss units, then Jet JWBS-9X can hardly be called a budget model. But it is equipped with a high-power engine. It drives the saw blade 0.3-1 cm wide. The working surface can be illuminated by a built-in lamp, and a comfortable parallel stop is also provided.

The powerful cast bed rests on 4 legs. Underneath them are rubber pads to help suppress vibration. All you need is a regular wing screw to tighten the blade. The basic package includes an angle stop equipped with a measuring scale. However, it is worth remembering about the limited power of the product.

If this indicator is critical, you should pay attention to Metabo BAS 318 Precision WNB... It is difficult to find a model equal to this band saw in terms of power. The motor develops an effort of almost 1 kW. The impulse is transmitted to the cutting unit thanks to the belt mechanism. Although the saw moves at a speed of 880 m per minute, it moves very smoothly without jerking. To provide the required speed and precisely set the direction of movement of the saw, flywheels equipped with rubber pads are used. Thanks to this, it is possible to fully process materials of different hardness. Illumination is provided. Precision WNB differs in an atypical design of the bed - it was placed on a trapezoidal platform. This solution is highly robust.

Returning to German products, it is worth highlighting "FDB Maschinen MJ 350N"... This band saw is exceptionally powerful and of excellent quality. The motor develops an effort of 0.75 kW, while the cut is made to a height of 20 cm. A very powerful bed is mounted on support legs. Carefully selected rubber pads dampen vibrations. The saw can work at an angle, make a smooth turn, or operate at a strictly verified angle.

There are no backlashes and errors when cutting wood with this tool. Excellent accuracy of work is guaranteed. The pulleys are optimally balanced. Users can choose between two operating speeds. Product reviews are quite supportive.

Jet JBS-12 ideally suited for lumber and wide board widths. The designers were able to provide a uniform, albeit very rapid impact on the material. The saw of this model is capable of performing both straight cuts and curly cuts from thick wood. The widest width of the workpieces to be sawn reaches 30 cm. The engine, which generates a force of up to 0.8 kW, helps to cut even very strong wood species. It should be borne in mind, however, that this unit weighs 60 kg.

Band saws of Russian production, such as "Enkor Corvette-35"... The device is very powerful and works at high speed. It is recommended for the most busy workshops. The tape moves at a speed of 15 m per second. This pace is enough for sawing various types of workpieces, not only wood, but also made of plastic. Bandsaw machine "Corvette-35" shipped to customers together with high stands.

The lift of the upper frame is sufficient to make even difficult cuttings easy. The work table is designed to leave room for both workpieces and the hands of the operators. Importantly, the rotating parts of the Russian-made saw are insulated with steel covers.This significantly increases the level of safety at work. The belt is supported by a special roller to avoid tearing or jamming.

Shipping kit "Corvette-35" includes a protractor to facilitate the oblique incision. The ability to vary the speed reduces the load on the motor. The device can be connected to 220 V networks. The cut is made to a depth of 20 cm, but it is quite difficult to rearrange the belt.

Subtleties of choice

The most important consideration for selecting the optimal band saws is the impeccable quality of the emerging boards. Any "dips", "waves" and so on are categorically unacceptable. In terms of power, these devices are divided into:

- professional;

- semi-professional;

- homemade.

For a home workshop, you should not buy very powerful units. Yes, they are very productive, but the power consumption will also increase significantly. In addition, high-powered devices take up a lot of space and generate a lot of noise. Small-sized mechanisms designed for the home are usually quieter. However, they are unlikely to cope with the processing of durable wood species.

The semi-professional product is recommended for small businesses and ancillary workshops. Such a tool can work for quite a long time, including when cutting hard material. But if you need to process large-diameter frozen forest, only professional devices are suitable. The cutting depth also plays an important role. It is directly proportional to the power of the motor. You also need to pay attention to the kerf width. The width of the processed boards depends on this indicator. The machines installed in large industries can cut workpieces up to 61 cm wide. It is required to check the degree of sharpening of the teeth, which affects the evenness of the cut. Saws that allow you to change the speed of work are clearly better than the regular versions.

But we must remember that a household tool rarely has such a function. The payment for auxiliary options is not very significant, but they are reflected in the convenience of work immediately. The ability to quickly tension the blades reduces the time wasted, and also reduces the labor intensity of the work. It is also advisable to choose versions with millimeter scales. They increase the accuracy of the cut, especially if there are 2 or more stops.

Usage Tips

It is important to consider that you will have to be careful when working with the band saw. Regular maintenance includes wiring and careful sharpening. These manipulations are quite complicated, and in the absence of work experience, it is advisable to use the help of service centers. You can sharpen saws with a working band with special wheels. The selection of sharpening devices is made in accordance with the strength of the instrument's teeth.

But the geometry of the sharpening parts is also determined by the technological parameters of the saw. Before sharpening, make sure that the teeth of the tool can cut surfaces as evenly as possible. Taking on such work, you cannot make jerks. A sufficient level of coolant must be checked in the grinding mechanism. The accuracy of the adjustment of the teeth depends on this. When the sharpening is complete, you need to inspect the band saw. Any burrs, debris and particles must be removed. Sharpening the tool is required strictly in goggles, while wearing a respirator. It is recommended to give preference to professional grade grinding machines.

Setting the teeth is just as important as sharpening them. The task of such manipulation is to reduce the friction force. Complex types of wiring are done only by trained professionals. It is also imperative to adjust the band saw. This procedure is required for each newly assembled machine and also after changing the blade. Cleaning of the pulleys is a must. It is needed even with stable dust protection. The setting also includes the required tension of the canvases. It is weakened if they plan not to work for 2-3 days.

See the next video for more details.

The comment was sent successfully.